In essence, an autoclave uses high-pressure saturated steam to kill microorganisms by irreversibly damaging their essential proteins. The intense heat causes these proteins to coagulate and lose their function, a process called denaturation, which lethally disrupts all cellular activity. This method is effective against a vast range of organisms, including bacteria, viruses, fungi, and even highly resistant bacterial spores.

The core principle is not just heat, but the use of pressurized steam to achieve temperatures well above the boiling point of water. This moist heat rapidly penetrates and destroys microorganisms far more efficiently than dry heat alone, making autoclaving the gold standard for sterilization.

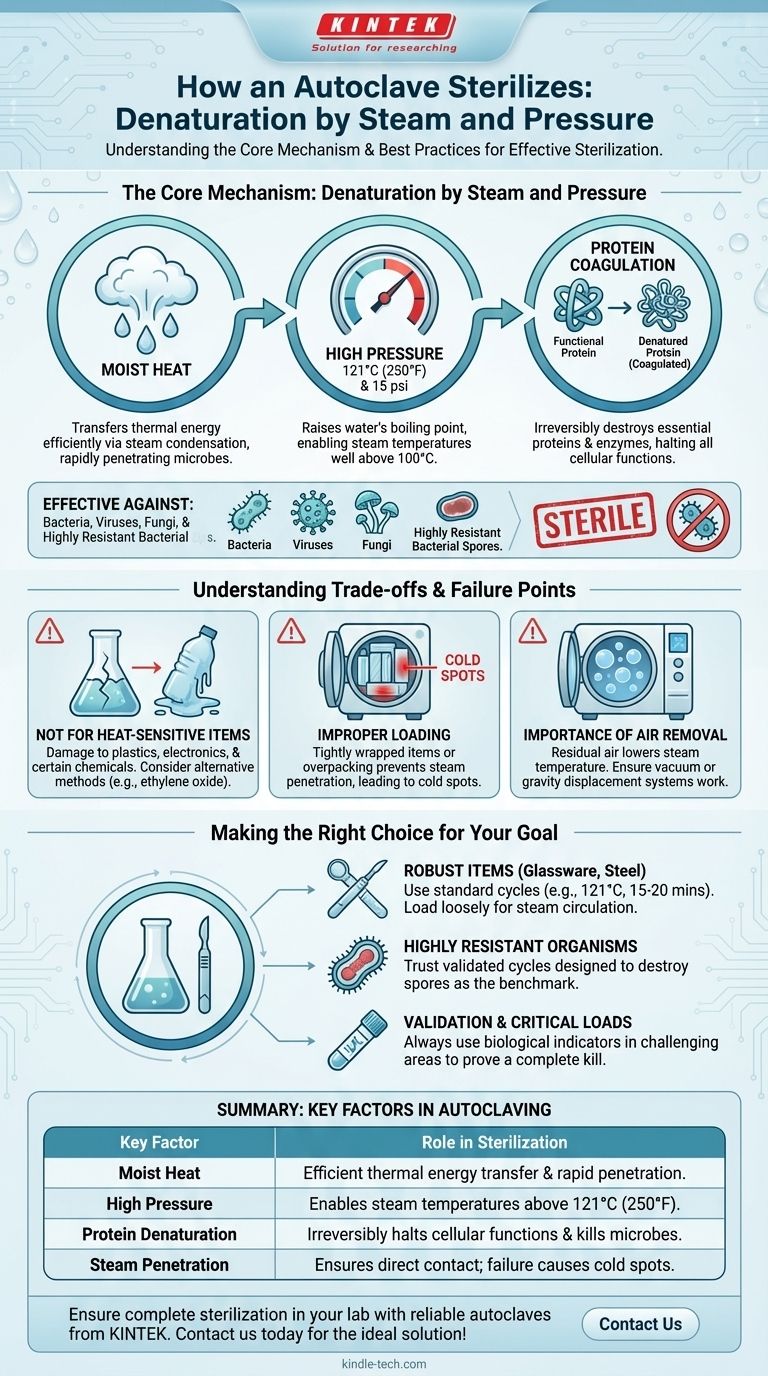

The Core Mechanism: Denaturation by Steam and Pressure

To understand why autoclaving is so definitive, we must look at how it weaponizes the physical properties of water. The process is a combination of temperature, pressure, and moisture, each playing a critical role.

The Power of Moist Heat

Heat kills microorganisms, but moist heat is significantly more effective than dry heat. Steam acts as an extremely efficient vehicle for transferring thermal energy.

When this superheated steam makes contact with a cooler item, it rapidly condenses into water, releasing a large amount of energy directly onto the surface and into the microorganism. This is far faster and more penetrating than simply baking an item in a dry oven.

The Critical Role of Pressure

An autoclave is fundamentally a pressure chamber. Its purpose is to manipulate the boiling point of water.

At standard atmospheric pressure, water boils at 100°C (212°F). By increasing the pressure inside the sealed chamber, the autoclave forces water to remain liquid at higher temperatures, allowing the steam generated to reach 121°C (250°F) or even higher.

This elevated temperature is what enables rapid and reliable sterilization, particularly for the most stubborn organisms.

The Fatal Blow: Protein Coagulation

The final step is biological. All life depends on proteins and enzymes to carry out essential functions like metabolism, replication, and structural integrity.

When exposed to the high temperatures delivered by the steam, these complex protein structures are violently shaken. The bonds holding them in their specific, functional shapes are broken, causing them to unfold and clump together, or coagulate.

This process is irreversible, much like cooking an egg white. A denatured protein cannot perform its job, leading to a complete shutdown of cellular machinery and the death of the microorganism.

Understanding the Trade-offs and Failure Points

While highly effective, the autoclaving process is not infallible. Its success depends on a correct understanding of its mechanism and limitations.

Not for Heat-Sensitive Items

The primary trade-off is that the very conditions that kill microorganisms—high heat and moisture—will also damage or destroy heat-labile materials.

Many plastics, sensitive electronics, and certain chemicals cannot withstand the autoclaving process. For these items, alternative sterilization methods like ethylene oxide gas or irradiation must be considered.

Proper Loading is Non-Negotiable

A common point of failure is improper loading of the autoclave chamber. The principle of sterilization relies on direct steam contact with every single surface.

If items are wrapped too tightly, containers are sealed, or the chamber is overpacked, "air pockets" can form. These pockets prevent steam from penetrating, creating cold spots where microorganisms can easily survive the cycle.

The Importance of Air Removal

For sterilization to succeed, virtually all air must be removed from the chamber and the load before the steam pressurizes. Modern autoclaves use vacuum cycles or gravity displacement systems to achieve this.

If residual air remains, it will lower the partial pressure of the steam, meaning the target temperature of 121°C will not be reached, even if the chamber gauge reads the correct pressure. This is a subtle but critical failure mode.

Making the Right Choice for Your Goal

Applying this knowledge correctly ensures that sterilization is not just an assumption, but a verifiable outcome.

- If your primary focus is sterilizing robust items like glassware or surgical steel: You can rely on standard autoclave cycles (e.g., 121°C at 15 psi for 15-20 minutes), but always ensure items are loaded loosely to permit full steam circulation.

- If you are dealing with highly resistant organisms like bacterial spores: Trust that the validated time and temperature of your autoclave cycle are specifically designed to destroy these targets, as they are the benchmark for achieving sterility.

- If you are validating your process or sterilizing critical loads: Always use biological indicators (vials containing heat-resistant spores) placed in the most challenging parts of the load to definitively prove the cycle achieved a complete kill.

Ultimately, understanding that an autoclave kills by forcing high-temperature steam into every crevice to denature proteins empowers you to use it as the powerful and reliable sterilization tool it was designed to be.

Summary Table:

| Key Factor | Role in Sterilization |

|---|---|

| Moist Heat | Transfers thermal energy efficiently via steam condensation, penetrating microbes rapidly. |

| High Pressure | Raises water's boiling point, enabling steam temperatures above 121°C (250°F). |

| Protein Denaturation | Irreversibly coagulates microbial proteins and enzymes, halting cellular functions. |

| Steam Penetration | Ensures direct contact with all surfaces; failure leads to cold spots and survival of microbes. |

Ensure complete sterilization in your lab with reliable autoclaves from KINTEK. Our equipment delivers precise high-pressure steam cycles to eliminate bacteria, viruses, and spores effectively. Trusted by laboratories worldwide for safety and compliance. Contact us today to find the ideal autoclave solution for your needs!

Visual Guide

Related Products

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

People Also Ask

- How do you calculate autoclave capacity? Avoid Sterilization Failures with the Right Formula

- How is high pressure generated in an autoclave? Unlock the Science of Sterilization & Synthesis

- What is the role of a high-temperature high-pressure autoclave in HTR simulation? Ensure Reactor Material Durability

- Are autoclaves safe? How to Ensure Sterilization Safety in Your Lab

- What is the lowest temperature for sterilization? Methods for Heat-Sensitive Materials

- What are the common sterilization methods in a laboratory? A Guide to Choosing the Right Technique

- Why is a high-pressure helium injection system used? Ensure Accurate Sample Recovery in Autoclaves

- Is an autoclave the same as a steam sterilizer? Understanding the Key to Reliable Sterilization