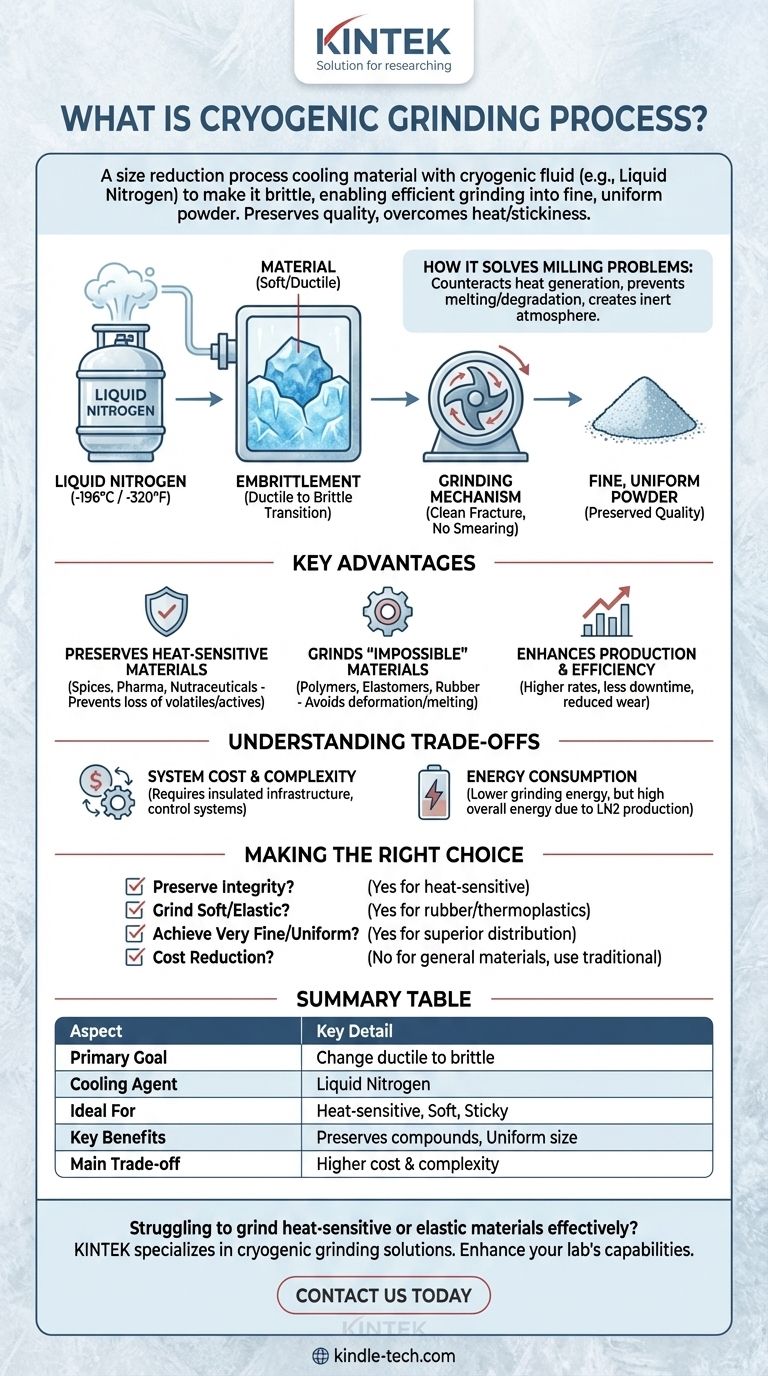

Cryogenic grinding, also known as freezer milling or cryomilling, is a size reduction process where a material is cooled to a very low temperature before or during grinding. This chilling, typically done with liquid nitrogen, makes the material brittle, allowing it to be fractured easily into a fine, uniform powder. This method preserves the material's original quality by preventing heat damage and overcoming the challenges associated with grinding soft, sticky, or elastic materials at ambient temperatures.

The fundamental purpose of cryogenic grinding is not just to cool a material, but to change its physical state from ductile to brittle. This transformation enables the efficient grinding of materials that would otherwise melt, smear, or clog standard grinding equipment.

How Cryogenic Grinding Solves a Fundamental Milling Problem

Traditional grinding generates significant heat through friction. For many materials, this heat is a critical problem, causing them to soften, melt, or degrade. Cryogenic grinding directly counteracts this issue.

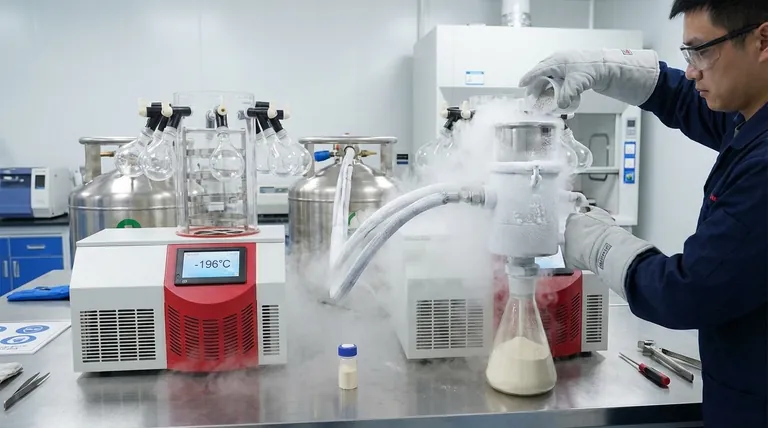

The Role of Cryogenic Fluids

The process begins by introducing a cryogenic fluid, most commonly liquid nitrogen, into the system. This has three immediate effects:

- Embrittlement: The extreme cold (liquid nitrogen is -196°C or -320°F) chills the material well below its glass transition temperature, making it hard and brittle like glass.

- Heat Absorption: The liquid nitrogen instantly absorbs the heat generated by the milling action, keeping the material in its brittle state throughout the process.

- Inerting: The nitrogen gas creates an oxygen-free atmosphere, which prevents oxidation and the potential for dust explosions, improving safety and preserving product quality.

The Grinding Mechanism

Once embrittled, the material is fed into a mill. The mechanical impact shatters the material along its natural fracture lines, rather than tearing or smearing it.

This results in a powder with a finer and more uniform particle size distribution than is often achievable with conventional grinding. The cold, inert environment also eliminates issues like caking and adhesion of powder inside the mill.

Key Advantages Over Traditional Grinding

Choosing this process is a strategic decision to overcome specific material challenges and achieve superior results.

Preserving Heat-Sensitive Materials

For materials with volatile or heat-sensitive components, cryogenic grinding is essential. It is widely used for spices, pharmaceuticals, and nutraceuticals, as it prevents the loss of volatile oils, flavors, and active ingredients that would be destroyed by the heat of conventional milling.

Grinding "Impossible" Materials

Many polymers, elastomers, and plastics are too soft, gummy, or elastic to grind at room temperature. They simply deform or melt. Cryogenic grinding makes it possible to reduce these materials—such as nylon, polyester, and rubber—into fine powders.

Enhancing Production and Efficiency

By preventing material from softening and sticking, cryogenic grinding leads to higher production rates and less downtime for cleaning. It reduces wear and tear on mill components, increasing equipment lifespan.

Understanding the Trade-offs

While powerful, cryogenic grinding is not a universal solution. Its benefits must be weighed against its specific operational requirements.

System Cost and Complexity

The primary trade-off is the infrastructure and operating cost associated with using a cryogenic fluid. This includes a storage tank for liquid nitrogen, insulated piping, and sophisticated control systems to manage temperature and flow, which adds to the initial capital investment.

Energy Consumption

While the grinding action itself may require less energy due to the material's brittleness, the overall energy balance must include the energy needed to produce the liquid nitrogen. The total energy efficiency of the system is often low (one study cites an exergy efficiency of 10.9%), making it a targeted solution for high-value problems rather than a general cost-saving measure.

Material Suitability

The process is most effective for materials that exhibit a distinct ductile-to-brittle transition at low temperatures. It provides little to no advantage for materials that are already hard and brittle at ambient temperatures, such as ceramics or minerals.

Making the Right Choice for Your Goal

To determine if cryogenic grinding is the correct approach, consider your primary objective.

- If your primary focus is preserving product integrity: Cryogenic grinding is the ideal choice for heat-sensitive materials like spices, active pharmaceutical ingredients (APIs), or products with volatile organic compounds.

- If your primary focus is grinding soft or elastic polymers: This is often the only viable method for achieving a fine powder from materials like rubber, thermoplastics, and elastomers.

- If your primary focus is achieving a very fine, uniform particle size: The clean fracture of an embrittled material often yields a superior particle distribution compared to the tearing action of ambient grinding.

- If your primary focus is simply cost reduction for a hard material: Traditional grinding methods are likely more economical and suitable for materials that do not pose heat-related or stickiness challenges.

Ultimately, cryogenic grinding is a specialized tool that unlocks processing capabilities for materials that are otherwise difficult or impossible to handle.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Primary Goal | Change material state from ductile to brittle for efficient grinding |

| Cooling Agent | Liquid Nitrogen (-196°C / -320°F) |

| Ideal For | Heat-sensitive materials, soft polymers, sticky/elastic substances |

| Key Benefits | Preserves volatile compounds, prevents melting/smearing, uniform particle size |

| Main Trade-off | Higher operational cost and complexity due to liquid nitrogen usage |

Struggling to grind heat-sensitive or elastic materials effectively?

KINTEK specializes in advanced laboratory equipment, including cryogenic grinding solutions. Our expertise helps you overcome material challenges, preserve product integrity, and achieve superior particle size distributions. Whether you're processing pharmaceuticals, polymers, or spices, we provide the right tools for optimal results.

Contact us today to discuss how our cryogenic grinding systems can enhance your lab's capabilities and efficiency. Let's find the perfect solution for your specific needs.

Get in touch with our experts now!

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the primary function of a freeze dryer in a laboratory setting? Preserve Delicate Materials with Sublimation

- Why does the manufacturer affect the price of a lab freeze dryer? Invest in Reliability, Innovation & Support

- What are the key reasons to use a freeze dryer in laboratories? Preserve Sample Integrity for Reliable Research

- What industries can benefit from freeze drying technology? Preserve Value in Pharma, Food & More

- What benefits do laboratory freeze dryers provide in chemical and biotechnological processes? Preserve Purity & Stability