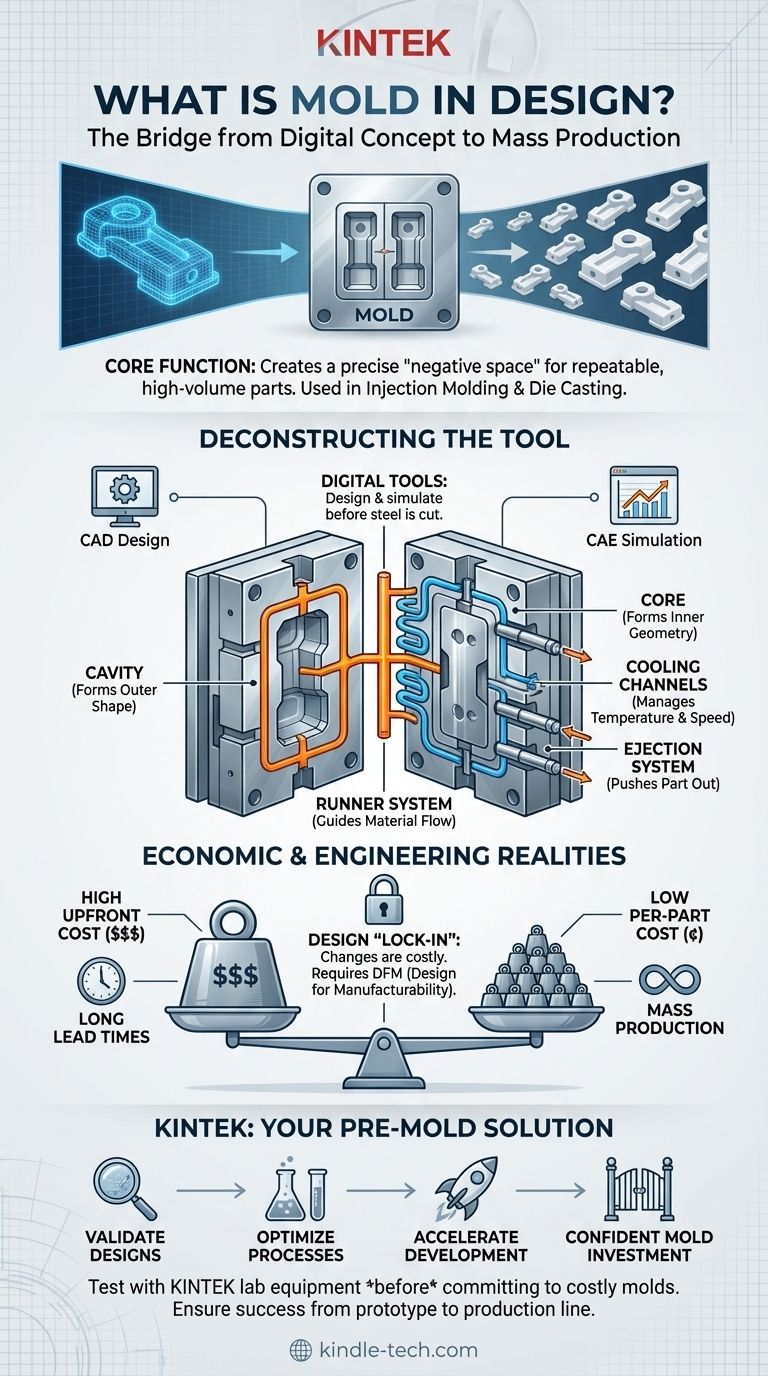

In the world of physical products, a mold is a custom-made industrial tool used to shape raw materials into a finished part. It is typically a hollowed-out block of hardened steel that functions as a negative of the final product's shape. Materials like molten plastic or metal are forced into this cavity under high pressure, allowed to cool and solidify, and then ejected as a perfectly formed, repeatable part. Mold design, therefore, is the critical engineering process of creating this tool.

A mold is the essential bridge between a digital design and a mass-produced physical product. The quality of the mold design itself directly dictates the final part's quality, the manufacturing cost, and the speed at which millions of units can be made.

From Digital File to Physical Part: The Role of the Mold

The Core Function: Creating a Negative Space

At its heart, a mold operates like a highly advanced industrial ice cube tray. It creates a precisely machined void—a "negative space"—that is the exact inverse of the part you intend to produce.

When raw material is injected into this void, it takes on the mold's shape. This process ensures that every single part produced is virtually identical to the last, which is the cornerstone of mass production.

Key Processes: Injection Molding and Die Casting

Molds are central to several high-volume manufacturing methods. The most common is plastic injection molding, where molten plastic is forced into the mold cavity.

A similar process for metals is die casting, where molten metal like aluminum or zinc is used instead. Both rely on the same principle: a robust, reusable mold to create consistent parts at high speed.

Why Molds are Essential for Mass Production

While a single part can be made with 3D printing, making one million parts this way is slow and expensive. Molds solve this problem.

After a significant upfront investment to create the mold, the cost to produce each individual part becomes incredibly low. This economy of scale is what makes consumer electronics, automotive components, and countless other everyday items affordable.

Deconstructing Mold Design: The Art and Science of the Tool

More Than Just the Part's Shape

Mold design is a highly specialized field of engineering that goes far beyond simply creating a negative of the product's geometry. The designer must account for how the material will behave and how the part can be manufactured efficiently.

The Cavity and Core

A simple mold is made of two halves. The cavity is the half that typically forms the outer, "cosmetic" surface of the part. The core is the other half that forms the inner, often unseen geometry. When these two steel blocks close, they form the complete void for the part.

The Runner System: Guiding the Material Flow

The mold designer must create a network of channels, called runners, that guide the molten material from the machine's nozzle into the cavity. The design of this system is critical for ensuring the cavity fills evenly and completely, preventing defects.

The Ejection System: Getting the Part Out

Once the part has cooled and solidified, it must be pushed out of the mold without damage. The mold designer incorporates an ejection system, which consists of multiple steel pins that press against the part to eject it from the core.

Cooling Channels: Managing Temperature

The speed of manufacturing is often limited by how quickly the part can cool. Mold designers engineer intricate cooling channels within the steel blocks, through which water or oil circulates to control the temperature and reduce cycle time.

The Role of Digital Tools (CAD/CAE)

Modern mold design is performed using digital tools. Engineers use CAD (Computer-Aided Design) software to model every component of the mold.

They then use CAE (Computer-Aided Engineering) software to run simulations. This allows them to predict and solve problems—like material flow issues or warping—before any expensive steel is cut, dramatically improving quality and shortening the design cycle.

Understanding the Trade-offs and Implications

High Upfront Cost, Low Per-Part Cost

The single biggest factor to understand about molds is their cost. A production-quality mold for a complex part can easily cost tens or even hundreds of thousands of dollars. This investment is only justified when producing thousands or millions of parts.

Long Lead Times

Creating a mold is a slow, meticulous process of machining hardened steel to incredible tolerances. The lead time to produce a finished mold can range from several weeks to many months, which must be factored into any product launch timeline.

The "Lock-in" Effect

Once a mold is made, the product's design is effectively "locked in." Making even a small change to the part design often requires expensive and time-consuming modifications to the steel mold, and in many cases, a completely new mold is needed.

The Need for "Design for Manufacturability" (DFM)

A product cannot be successfully molded unless it is designed to be moldable from the start. This principle, known as Design for Manufacturability (DFM), involves rules like including slight angles (draft angles) on walls so the part can be ejected, and maintaining uniform wall thickness to prevent warping. This requires close collaboration between the product designer and the mold engineer.

How This Applies to Your Product Development

Understanding molds is fundamental to making strategic decisions in product development.

- If your primary focus is rapid prototyping or low-volume production: Avoid molds and their high initial costs by using 3D printing or urethane casting.

- If your primary focus is launching a mass-market physical product: Plan for the mold's high cost and long lead time as a critical component of your budget and timeline from day one.

- If your primary focus is improving an existing molded product: Recognize that any design change is a significant engineering task that will require expensive and time-consuming modifications to the tool.

Ultimately, understanding the mold is understanding the fundamental economics and engineering constraints of bringing a physical product to the world.

Summary Table:

| Aspect | Description |

|---|---|

| Core Function | A hollowed-out steel tool (negative space) that shapes raw materials into finished parts. |

| Key Processes | Plastic Injection Molding, Die Casting. |

| Main Advantage | High upfront cost leads to very low per-part cost for high-volume production. |

| Key Consideration | Requires Design for Manufacturability (DFM) and locks in design after creation. |

Ready to bridge the gap between your digital design and mass production?

The principles of mold design are critical for any successful physical product launch. At KINTEK, we specialize in providing the high-quality lab equipment and consumables needed for prototyping, material testing, and process validation—essential steps before committing to a costly mold.

We help you:

- Validate Designs: Test material properties and behavior with our reliable equipment.

- Optimize Processes: Ensure your manufacturing parameters are dialed in.

- Accelerate Development: Get the precise tools you need to move from concept to production with confidence.

Don't let manufacturing challenges slow you down. Contact our experts today to discuss how KINTEK's solutions can support your product development journey from prototype to production line.

Visual Guide

Related Products

- Special Heat Press Mold for Lab Use

- Special Shape Press Mold for Lab

- Polygon Press Mold for Lab

- Multi-Punch Rotary Tablet Press Mold Ring for Rotating Oval and Square Molds

- Assemble Lab Cylindrical Press Mold

People Also Ask

- Why is it necessary to apply alumina powder to graphite molds for TiC10/Cu-Al2O3? Ensure Smooth Release.

- What role do graphite dies play during the Spark Plasma Sintering (SPS) of ceramic powders? Enhance Sintering Efficiency

- What is the difference between injection mold and insert mold? A Guide to Multi-Material Parts

- What is the function of high-purity graphite molds? Enhance Vacuum Hot Pressing for Al-Matrix Composites

- What are the advantages of a 3 plate mold? Unlock Superior Gating and Part Quality

- What role does a steel pellet die play in molding BZY20 ceramics? Ensure Uniform Density & Precision.

- What functions do high-temperature molds perform in vacuum hot pressing? Enhance Metal Layered Composite Precision

- What is the role of graphite molds in vacuum hot-press sintering? Optimize Ti/Al2O3 Composite Bonding