In the food industry, a rotary vacuum evaporator is a precision tool for concentrating flavors and extracting delicate aromas without damaging them with heat. By lowering the pressure inside the system, a rotovap allows liquids like fruit juice or alcohol to boil at very low temperatures, sometimes even room temperature. This process carefully separates liquids, preserving the volatile compounds that define a food's fresh taste and scent, which would otherwise be destroyed by traditional heating methods.

The true value of a rotary vacuum evaporator in food applications lies not in simple water removal, but in its ability to gently separate components at low temperatures. This unlocks the potential to create intensely flavorful concentrates, pure aromatic essences, and unique infusions that are impossible to achieve with conventional cooking.

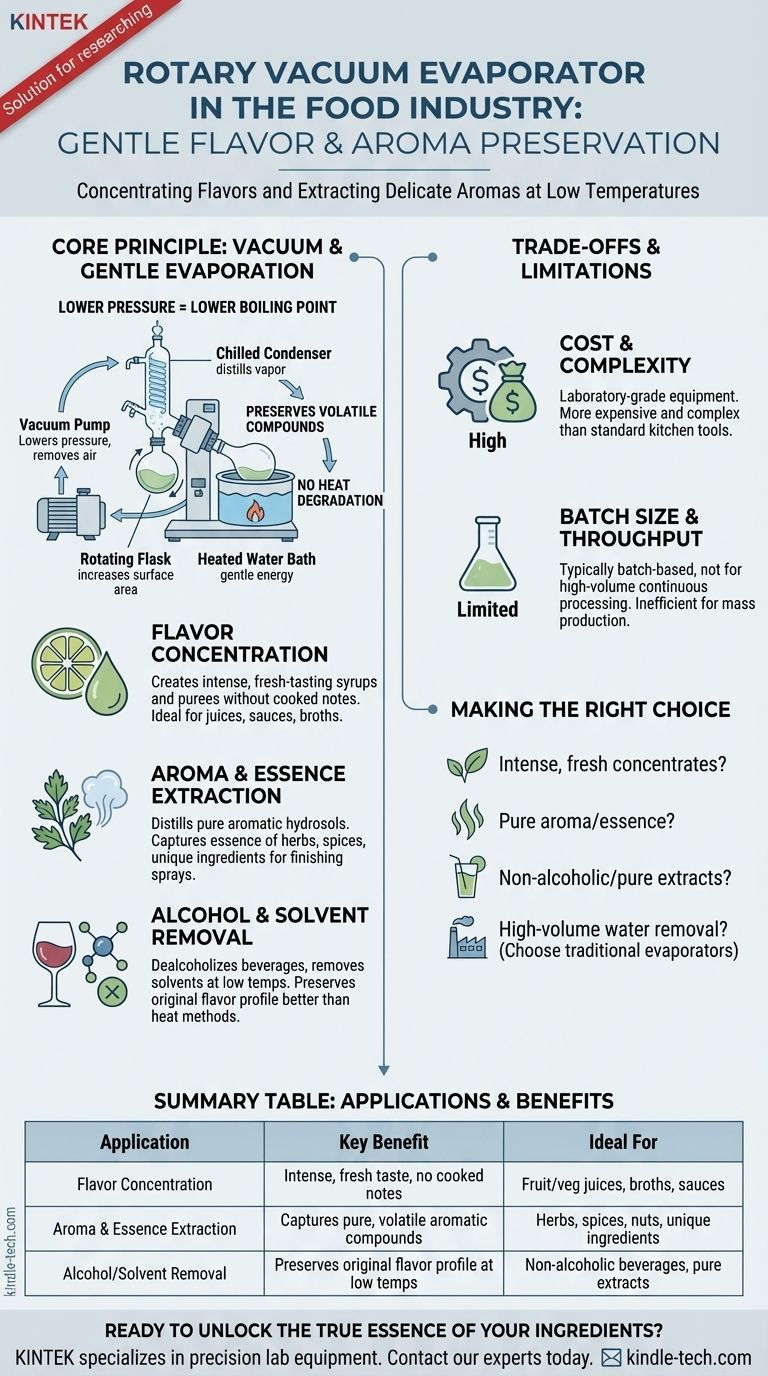

The Core Principle: Gentle Evaporation Under Vacuum

At its heart, the rotovap manipulates a fundamental law of physics to protect the integrity of food. It solves the single biggest problem in flavor concentration: heat degradation.

How Vacuum Changes the Game

Every liquid has a boiling point, but that point is dependent on the atmospheric pressure above it. By using a vacuum pump to remove air from the system, a rotovap dramatically lowers the pressure.

This reduction in pressure makes it much easier for molecules to escape the liquid and become a vapor. The result is a significantly lower boiling point, allowing for evaporation without aggressive heating.

Preserving Volatile Compounds

The "flavor" and "aroma" of food are carried by highly volatile organic compounds. These molecules are fragile and easily destroyed or altered by heat, which is why a fresh strawberry tastes different from strawberry jam.

Because the rotovap operates at low temperatures, it evaporates water or alcohol while leaving these delicate flavor and aroma compounds behind in a more concentrated form.

The Key Components in Action

A rotary vacuum evaporator works through a system of coordinated parts. A rotating flask increases the surface area of the liquid, a heated water bath provides gentle energy, the vacuum pump lowers the boiling point, and a chilled condenser coil turns the evaporated vapor back into a separate, distilled liquid.

Key Applications in Food Production

This ability to gently separate liquids opens up a range of applications, from industrial product development to high-end culinary arts.

Flavor Concentration

The most common application is creating potent concentrates. By evaporating the water from a fruit or vegetable juice, you can produce a syrup with an intense, fresh flavor, completely avoiding the "cooked" or caramelized notes that come from traditional reduction.

This is ideal for creating powerful fruit purees, vegetable essences, or concentrated broths and stocks.

Aroma and Essence Extraction

A rotovap can distill the aromatic compounds from an ingredient into a pure, clear liquid called a hydrosol or essence.

Chefs and food scientists use this to capture the essence of fresh herbs, toasted nuts, spices, or even non-traditional items like soil or leather for use as a finishing spray or an ingredient in a larger formulation.

Alcohol and Solvent Removal

The technology is also highly effective for dealcoholization. It can remove ethanol from wine or beer at a low temperature, which helps preserve the beverage's original flavor profile better than heat-based methods.

Similarly, if a solvent like food-grade ethanol is used to extract a flavor from a solid, the rotovap can then remove that solvent to leave behind a pure, concentrated extract.

Understanding the Trade-offs and Limitations

While powerful, the rotary vacuum evaporator is a specialized tool with specific constraints.

Cost and Complexity

This is laboratory-grade equipment. It is significantly more expensive and complex to operate than standard kitchen or industrial machinery like a boiling pot or steam-jacketed kettle.

Batch Size and Throughput

Rotovaps are typically batch-based systems, meaning they process a limited volume at a time. While larger industrial-scale models exist, they are not suited for the kind of high-volume, continuous processing required for mass-market products like tomato paste.

Not a Universal Solution

For simple water removal where the preservation of delicate top-notes is not a priority, other industrial evaporators are far more cost-effective and efficient. The rotovap is reserved for high-value products where flavor and aroma fidelity is the primary goal.

Making the Right Choice for Your Goal

Deciding whether to use a rotovap depends entirely on the desired end product.

- If your primary focus is creating intense, fresh-tasting concentrates: Use a rotovap to reduce juices, broths, or sauces without introducing cooked flavors.

- If your primary focus is capturing a pure aroma or essence: Use it to distill the volatile compounds from herbs, spices, or other ingredients into a hydrosol.

- If your primary focus is producing non-alcoholic beverages or pure extracts: It provides a superior, low-temperature method for removing alcohol or other food-grade solvents.

- If your primary focus is simple, high-volume water removal: Consider more traditional industrial evaporators, as a rotovap will be inefficient and not cost-effective.

Ultimately, the rotary vacuum evaporator empowers food creators to deconstruct and concentrate the very essence of ingredients with unparalleled precision.

Summary Table:

| Application | Key Benefit | Ideal For |

|---|---|---|

| Flavor Concentration | Intense, fresh taste without cooked notes | Fruit/vegetable juices, broths, sauces |

| Aroma & Essence Extraction | Captures pure, volatile aromatic compounds | Herbs, spices, nuts, unique ingredients |

| Alcohol/Solvent Removal | Preserves original flavor profile at low temps | Non-alcoholic beverages, pure extracts |

Ready to unlock the true essence of your ingredients?

KINTEK specializes in precision lab equipment for the food industry. Our rotary vacuum evaporators are engineered to help you create intensely flavorful concentrates and pure aromatic extracts without heat degradation.

Whether you're developing new products in R&D or scaling up for production, our solutions are designed to meet your specific needs for quality and efficiency.

Contact our experts today to find the perfect system for your food science and culinary applications!

Visual Guide

Related Products

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Ceramic Evaporation Boat Set Alumina Crucible for Laboratory Use

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

People Also Ask

- What type of wastes are used for the pyrolysis treatment? Unlock Value from Organic Waste Streams

- What is the bias of sputtering RF? How a Negative DC Self-Bias Enables Insulator Sputtering

- What is the process of sintering finishing? From Near-Net Shape to Final Precision

- What is slow and fast pyrolysis? Choosing the Right Process for Bio-Oil or Biochar

- Why is sintering easier in the presence of a liquid phase? Unlock Faster, Lower-Temperature Densification

- What are some examples of where brazing is used? Join Dissimilar Metals with High-Strength, Leak-Proof Joints

- What are the advantages of electron beam method? Achieve Speed, Cost Savings, and Material Integrity

- Why is potassium bromide used in FTIR? The Key to Accurate Solid Sample Analysis