The fundamental difference between wet and dry vacuum systems lies in the mechanism used for sealing and lubrication. Wet vacuum pumps use a fluid, typically oil or water, to create seals and lubricate moving parts. In contrast, dry vacuum pumps operate without any fluid in the vacuum-generating space, relying instead on extremely precise engineering and tight mechanical tolerances between components.

The choice between a wet and dry vacuum pump is not merely a technical preference; it is a critical decision about the acceptable level of contamination in your process. Wet pumps trade potential contamination for lower cost, while dry pumps prioritize purity at a higher initial investment.

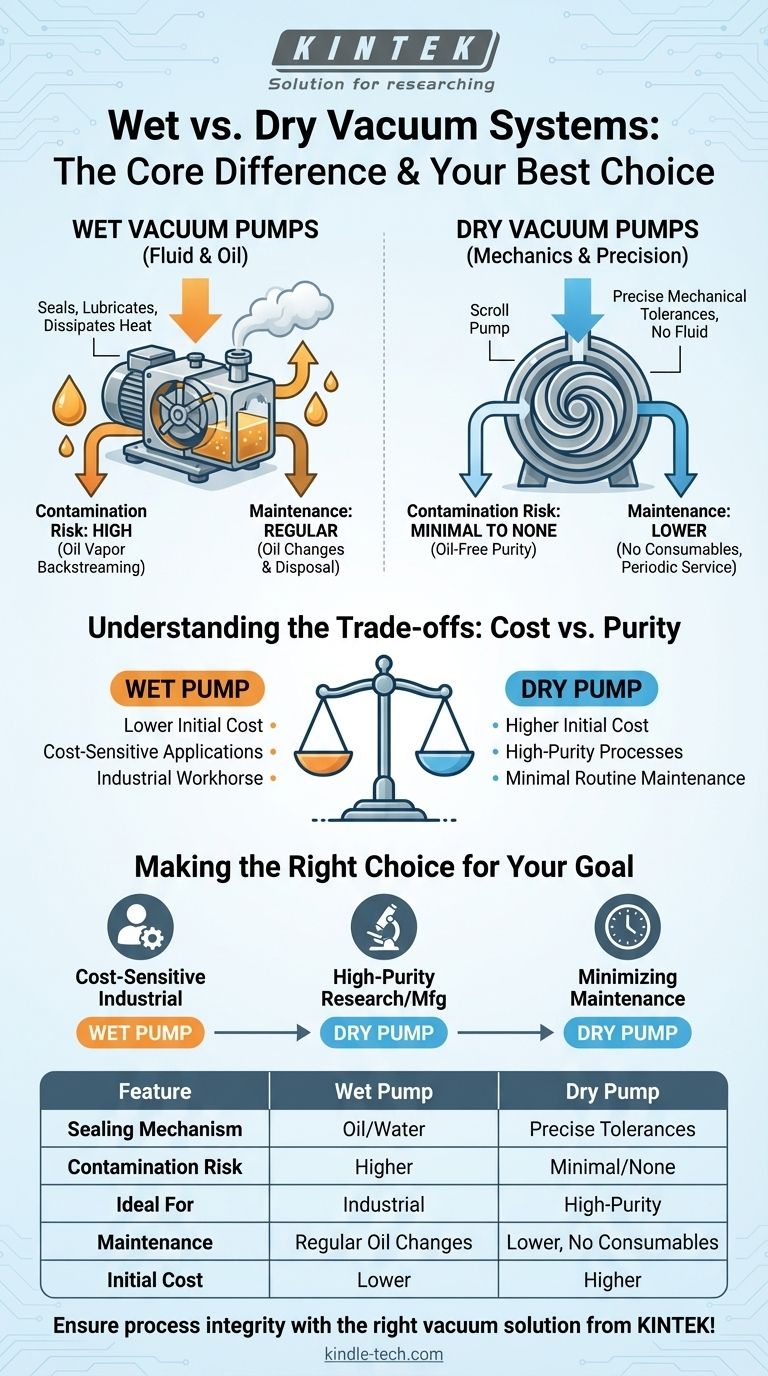

The Core Difference: Fluid vs. Mechanics

The presence or absence of a sealing fluid dictates the entire design, performance, and application range of a vacuum pump.

How Wet Pumps Work

Wet pumps, such as the common rotary vane pump, use oil to fill the gaps between moving parts. This oil serves three critical functions: it seals the compression chambers, lubricates the rotating components to prevent wear, and helps dissipate heat generated during gas compression.

This design is robust, reliable, and has been a workhorse in general vacuum applications for decades.

How Dry Pumps Work

Dry pumps achieve a vacuum without any fluid in the path of the evacuated gas. Instead, they use complex designs like scrolls, lobes, or screws that move in close proximity without touching.

The effectiveness of these pumps depends entirely on the precision of their manufacturing. The tiny, consistent gap between moving parts is small enough to prevent significant gas leakage, allowing the pump to function effectively without lubrication or fluid sealing.

Why This Distinction Matters for Your Application

Understanding the core mechanical difference is the first step. The more important consideration is how this difference impacts your specific goal.

The Critical Issue of Contamination

The oil in a wet pump can create oil vapor that "backstreams" or migrates back into the vacuum chamber. This introduces hydrocarbon contamination, which is unacceptable for sensitive processes.

Applications in semiconductor manufacturing, surface science analysis, mass spectrometry, and medical device fabrication require a "clean" vacuum. Any contamination can ruin samples, alter results, or cause product failure. Dry pumps are the definitive solution for these environments.

Maintenance and Operational Demands

Wet pumps require regular maintenance, including monitoring oil levels, changing the oil, and properly disposing of the contaminated waste oil. This adds to the operational cost and labor requirements.

Dry pumps eliminate these tasks entirely. While they may require periodic servicing (like tip seal replacement in a scroll pump), their routine operational demands are significantly lower. However, if a major failure occurs, repairs can be more complex and costly due to their precision engineering.

Understanding the Trade-offs: Cost vs. Purity

The decision often comes down to balancing your budget against your process requirements.

Upfront Investment

Wet vacuum pumps are generally less expensive to purchase. Their simpler, long-established design makes them a more economical choice for applications where oil vapor is not a concern.

Dry pumps have a significantly higher initial cost. The precision machining required to achieve tight tolerances without contact is a complex and expensive manufacturing process.

Total Cost of Ownership

While the initial purchase price of a wet pump is lower, you must factor in the ongoing costs of consumables (oil, filters) and waste disposal.

For dry pumps, the higher initial cost is offset by lower routine maintenance and the elimination of consumables. More importantly, for sensitive applications, the cost of a single contaminated batch often far exceeds the price premium of a dry pump.

Making the Right Choice for Your Goal

Selecting the correct pump technology is essential for ensuring process integrity and operational efficiency.

- If your primary focus is cost-sensitive industrial applications: A wet pump is a robust and economical solution for tasks like vacuum forming, degassing, or backing diffusion pumps where minor oil vapor is tolerable.

- If your primary focus is high-purity research or manufacturing: A dry pump is non-negotiable to prevent hydrocarbon contamination and ensure the integrity and repeatability of your results.

- If your primary focus is minimizing routine maintenance: A dry pump offers a clear advantage by eliminating the need for regular oil changes, providing more consistent and unattended operation.

Ultimately, choosing the right vacuum system is about matching the technology's inherent cleanliness to the purity your work demands.

Summary Table:

| Feature | Wet Vacuum Pump | Dry Vacuum Pump |

|---|---|---|

| Sealing Mechanism | Uses oil or water | Relies on precise mechanical tolerances |

| Contamination Risk | Higher (oil vapor backstreaming) | Minimal to none (oil-free) |

| Ideal For | Cost-sensitive industrial applications | High-purity processes (semiconductors, research) |

| Maintenance | Regular oil changes and disposal | Lower routine maintenance, no consumables |

| Initial Cost | Lower | Higher |

Ensure process integrity with the right vacuum solution from KINTEK!

Choosing between a wet and dry vacuum system is critical for your lab's success. Whether you need a cost-effective workhorse for industrial applications or a contamination-free pump for sensitive research, KINTEK has the expertise and equipment to meet your specific needs. Our range of high-quality lab equipment and consumables is designed to deliver reliability and performance.

Don't let the wrong pump compromise your results. Contact our experts today to discuss your requirements and find the perfect vacuum system for your laboratory.

Visual Guide

Related Products

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Laboratory Benchtop Water Circulating Vacuum Pump for Lab Use

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- How long does heat treatment of steel take? From Minutes to Days for Your Project

- What is magnetron sputtering coating? A High-Performance Thin Film Deposition Process

- What kinds of components are produced through the sintering process? Essential Parts for High-Performance Industries

- What is the difference between biomass and biomass energy? Unlock the Power of Renewable Resources

- Is pyrolysis for converting biomass to more useful liquid? Unlock Bio-Oil, Biochar & Syngas

- What is a slow pyrolysis? A Guide to Maximizing Biochar Production from Biomass

- Which is a disadvantage of the carburizing process? High Costs, Complex Control, and Post-Processing Demands

- How to measure the thickness of coating? Choose the Right Method for Your Substrate