In agitated vessels, heat transfer is the controlled exchange of thermal energy between the vessel's contents and an external source or sink. This process is fundamental for managing the temperature of chemical reactions, crystallizations, or mixing operations. It is typically accomplished using a heating or cooling medium that flows through a jacket surrounding the vessel or through internal coils, with the agitator playing the most critical role in determining the rate of heat exchange.

The effectiveness of heat transfer in a stirred tank is not dictated by the temperature of the heating or cooling fluid alone. It is fundamentally controlled by the agitator, which creates the turbulence needed to break down the insulating fluid layer at the vessel wall, thereby governing the overall efficiency of the process.

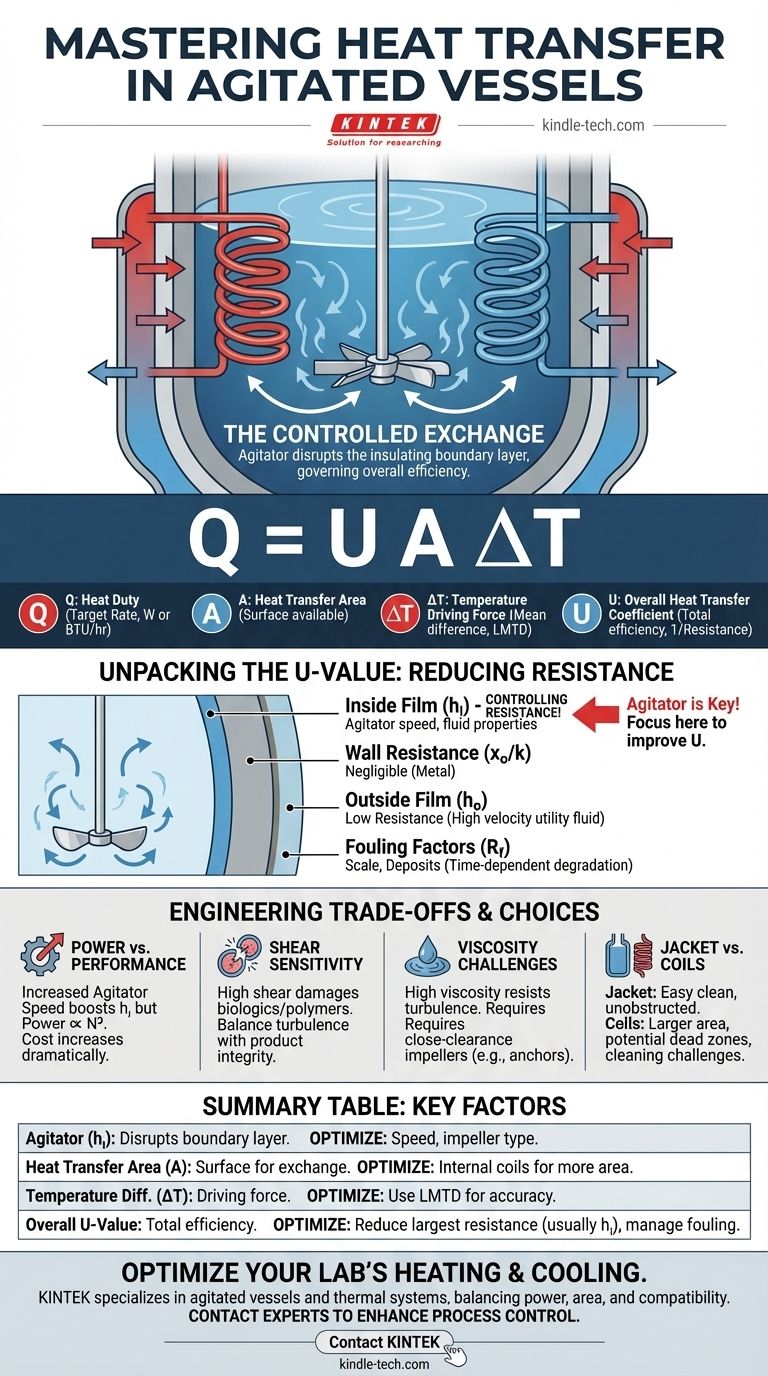

The Fundamental Equation: Q = U A ΔT

To understand and control heat transfer, we rely on a core engineering equation. Each variable in this equation represents a distinct aspect of the system that can be engineered for a desired outcome.

Q: The Heat Duty

Q represents the rate of heat transfer required, measured in units like Watts (W) or BTU/hr. This is your process target. It's the amount of energy you need to add or remove per unit of time to achieve your goal, whether that's heating reactants to a specific temperature or removing the heat generated by an exothermic reaction.

A: The Heat Transfer Area

A is the physical surface area available for heat exchange. This is the surface area of the vessel wall that is in contact with the heating/cooling jacket, or the total surface area of any internal coils. For a given vessel, the area is largely fixed, but the choice between a jacket and internal coils is a key design decision.

ΔT: The Temperature Driving Force

ΔT, or the mean temperature difference, is the driving force for heat transfer. For processes where temperatures change over time (like a batch heating up), we use the Log Mean Temperature Difference (LMTD). It accurately averages the temperature difference between the process fluid and the utility fluid at the inlet and outlet, providing a true representation of the thermal driving force.

U: The Overall Heat Transfer Coefficient

U is the overall heat transfer coefficient. This is the most complex and critical variable in the equation, as it quantifies the total resistance to heat flow between the bulk process fluid and the bulk utility fluid. A higher U-value means less resistance and more efficient heat transfer.

Unpacking the Overall Heat Transfer Coefficient (U)

The overall resistance to heat transfer (which is the inverse of U, or 1/U) is the sum of several individual resistances in series, much like electrical resistors. To improve heat transfer, you must identify and reduce the largest resistance in the chain.

The Inside Film Coefficient (hᵢ)

This coefficient represents the thermal resistance of the thin, stagnant layer of process fluid that clings to the inside wall of the vessel. In agitated vessels, this is almost always the controlling resistance.

The agitator's primary job is to create turbulence and shear that disrupts this "boundary layer," making it thinner and dramatically reducing its resistance. The value of hᵢ is therefore a direct function of agitator speed, impeller type, and fluid properties (viscosity, density, thermal conductivity).

The Wall Resistance (xₒ / k)

This is the resistance offered by the physical material of the vessel wall itself. For standard metal vessels (like stainless steel), the thermal conductivity (k) is high and the wall thickness (xₒ) is relatively small, making this resistance negligible compared to the fluid films.

The Outside Film Coefficient (hₒ)

This represents the resistance of the fluid film in the jacket or on the outside of the coils. Because utility fluids like steam, hot oil, or cooling water are typically pumped at high velocities to promote turbulence, this resistance is often significantly smaller than the inside film resistance (hᵢ).

Fouling Factors (R_f)

Over time, deposits, scale, or product buildup can form on either the inside or outside heat transfer surfaces. This fouling adds another layer of thermal resistance. In design, engineers include a "fouling factor" to account for this expected degradation in performance over the life of the equipment, ensuring the system still works even when it's not perfectly clean.

Understanding the Trade-offs

Optimizing heat transfer is not a simple matter of maximizing every variable. It involves balancing competing engineering and economic factors.

Agitation Power vs. Performance

Increasing agitator speed boosts turbulence and improves the inside film coefficient (hᵢ). However, the power required by the agitator motor increases with the cube of its speed (Power ∝ N³). This means a small increase in heat transfer performance can demand a massive increase in energy consumption and operational cost.

Shear Sensitivity

Many modern processes, particularly in biotechnology and polymer production, involve shear-sensitive materials. The high-speed, turbulent mixing that is excellent for heat transfer can destroy delicate cells or break down long-chain molecules, ruining the product. In these cases, heat transfer goals must be balanced against the mechanical limitations of the product.

The Challenge of Viscosity

High-viscosity fluids are exceptionally difficult for heat transfer. They resist turbulent flow, creating a thick, insulating boundary layer at the vessel wall that is very difficult for standard agitators to disrupt. This results in an extremely low inside film coefficient (hᵢ) and poor performance.

Jacket vs. Internal Coils

A jacket is simple, easy to clean, and leaves the vessel interior unobstructed for optimal mixing. However, it has a relatively low heat transfer area-to-volume ratio, which becomes a bottleneck in large vessels.

Internal coils offer a much larger heat transfer area for the same vessel volume, enabling far more rapid heating or cooling. However, they are difficult to clean and can create "dead zones" in the mixing pattern if not designed properly.

Making the Right Choice for Your Process

Your approach to heat transfer must be dictated by the specific demands of your process fluid and operational goals.

- If your primary focus is rapid heating/cooling of low-viscosity fluids: Prioritize creating turbulence with high-speed impellers (e.g., turbines) and consider using internal coils to maximize the available heat transfer area.

- If your primary focus is handling a high-viscosity product: Use close-clearance impellers like anchors or helical ribbons, which physically scrape the insulating boundary layer from the vessel wall to ensure heat transfer.

- If your primary focus is processing shear-sensitive materials: Employ large-diameter, low-speed impellers that promote bulk fluid motion and temperature uniformity without creating the intense, damaging shear found at the tips of high-speed impellers.

- If your primary focus is long-term operational efficiency: Design your system with realistic fouling factors and choose a jacket or coil configuration that balances performance with the practical need for cleaning and maintenance.

Ultimately, mastering heat transfer in an agitated vessel means intentionally designing a system that controls the fluid dynamics at the heat transfer surface.

Summary Table:

| Key Factor | Role in Heat Transfer | How to Optimize |

|---|---|---|

| Agitator (hᵢ) | Disrupts insulating fluid layer at wall (controlling resistance) | Increase speed (turbulence); choose correct impeller type |

| Heat Transfer Area (A) | Surface area for energy exchange (jacket/coils) | Use internal coils for larger area; jackets for simplicity |

| Temperature Difference (ΔT) | Driving force for heat flow | Use LMTD for accurate batch process calculation |

| Overall U-Value | Total system efficiency (1/U = sum of resistances) | Reduce largest resistance (usually hᵢ); manage fouling |

Optimize your lab's heating and cooling processes with the right equipment.

Whether you are managing precise chemical reactions, handling high-viscosity materials, or working with shear-sensitive biologics, effective heat transfer is critical for your results. KINTEK specializes in lab equipment and consumables, including agitated vessels and heating/cooling systems designed for superior thermal performance.

We can help you select a system that balances agitator power, heat transfer area, and material compatibility for your specific application—ensuring efficiency and protecting your product integrity.

Ready to enhance your process control? Contact our experts today to discuss your laboratory's needs.

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Super Sealed Electrolytic Electrochemical Cell

- 20L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- High Temperature Constant Temperature Heating Circulator Water Bath Chiller Circulator for Reaction Bath

People Also Ask

- What is a high pressure reactor? Unlock Chemical Reactions with Precision Control

- Why is a laboratory continuous flow reactor preferred over a closed reactor? Optimize Methane Reforming Precision

- What function does a pyrolysis reactor serve for LDPE waste? Optimize Plastic-to-Fuel Thermal Cracking

- What is the function of a high-pressure stainless steel autoclave in the catalytic conversion of cellulose into sugar alcohols?

- Why is a PTFE-lined high-pressure autoclave required for hydrothermal doping? Achieve Pure Graphene Synthesis

- How do high-temperature reactors utilize gasifying agents to convert MSW into syngas? Efficient Waste-to-Energy Secrets

- Which physical conditions are simulated by high-pressure autoclaves? Precise SCWR Environment Replication

- What is the function of a high-pressure reactor in nitrogen-doping carbon supports? Enhance Catalyst Nucleation