The primary advantage of vacuum evaporation is its ability to significantly lower the boiling point of a substance. By reducing the ambient pressure, less heat energy is required to transform a liquid into a gas. This makes the entire process faster, far more energy-efficient, and suitable for materials that would be damaged or destroyed by the high temperatures needed for evaporation at normal atmospheric pressure.

By removing the obstacle of atmospheric pressure, vacuum evaporation allows substances to boil at much lower temperatures. This fundamental principle saves significant energy, protects heat-sensitive materials, and enables high-purity processes that would be impossible in open air.

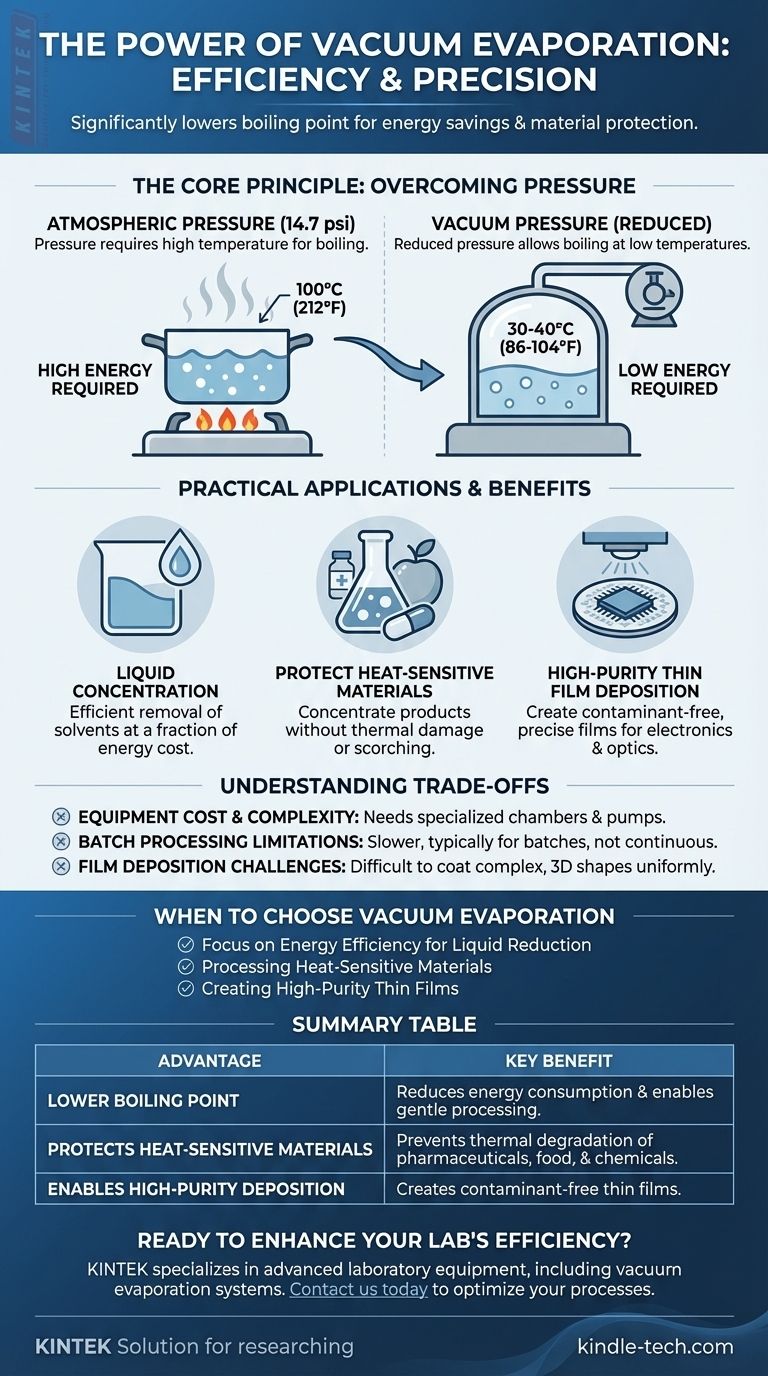

The Core Principle: Overcoming Atmospheric Pressure

To understand the advantage of a vacuum, we must first revisit what "boiling" actually is. It's a simple concept that is entirely dependent on pressure.

What is Boiling?

A liquid boils when the pressure of its own vapor equals the pressure of the environment surrounding it. At sea level, the weight of the atmosphere exerts significant pressure (about 14.7 psi), forcing water to reach 100°C (212°F) before it can boil.

How a Vacuum Changes the Equation

A vacuum chamber artificially removes most of the air, drastically lowering the environmental pressure. With very little pressure pushing down on the liquid's surface, its molecules can escape into a vapor phase with much less energy.

For water, this effect is dramatic. Under a partial vacuum, water can boil at a gentle 30-40°C (86-104°F) instead of a harsh 100°C. This is the central benefit that unlocks all other advantages.

Practical Applications of Low-Temperature Evaporation

This ability to evaporate materials at low temperatures has profound implications across different industries, from waste treatment to high-tech manufacturing.

For Liquid Concentration and Purification

In applications like waste water treatment or food concentration, the goal is to remove water efficiently. Using a vacuum allows for this at a fraction of the energy cost.

This also enables the processing of heat-sensitive materials. Products like pharmaceuticals, fruit juices, and milk can be concentrated without scorching them or destroying their essential compounds. The evaporated water can also be recovered as high-purity distilled water, as contaminants are left behind.

For High-Purity Thin Film Deposition

In electronics and optics, vacuum evaporation is used to deposit ultra-thin layers of material onto a substrate (a process known as Physical Vapor Deposition, or PVD).

Here, the vacuum serves two critical functions. First, it removes atmospheric gases like oxygen and nitrogen, which would otherwise react with and contaminate the vaporized material. This ensures a high-purity film.

Second, the absence of air molecules allows the vaporized material to travel in a straight, uninterrupted line from the source to the target. This line-of-sight trajectory is essential for precise deposition.

Understanding the Trade-offs

While powerful, vacuum evaporation is not a universal solution. The benefits come with clear trade-offs that must be considered.

Equipment Cost and Complexity

The most obvious downside is the need for specialized equipment. Vacuum chambers, robust seals, and powerful pumps are required to create and maintain the low-pressure environment, representing a significant upfront investment.

Batch Processing Limitations

Many vacuum evaporation systems operate in batches. The chamber must be sealed, pumped down, run, vented, and then opened. This cycle can be slower and less suited for high-volume, continuous production compared to some atmospheric processes.

Challenges in Film Deposition

The line-of-sight trajectory that is a benefit for purity can also be a drawback. It makes it difficult to coat the surfaces of complex, three-dimensional objects uniformly without sophisticated rotation and fixture systems. Certain materials, especially complex alloys, can also be difficult to evaporate consistently.

When to Choose Vacuum Evaporation

Your decision to use vacuum evaporation should be based entirely on whether its core benefits solve your specific problem.

- If your primary focus is energy efficiency for liquid reduction: Vacuum evaporation is superior, as it dramatically lowers the energy required to boil water or other solvents.

- If your primary focus is processing heat-sensitive materials: Vacuum evaporation is often the only viable choice to concentrate a product without causing thermal damage.

- If your primary focus is creating high-purity thin films: A vacuum is non-negotiable to prevent contamination from atmospheric gases and enable precise, line-of-sight deposition.

Ultimately, leveraging a vacuum transforms evaporation from a brute-force heating process into a precise, efficient, and controlled physical phenomenon.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Lower Boiling Point | Reduces energy consumption and enables gentle processing. |

| Protects Heat-Sensitive Materials | Prevents thermal degradation of pharmaceuticals, food, and chemicals. |

| Enables High-Purity Deposition | Creates contaminant-free thin films for electronics and optics. |

Ready to enhance your lab's efficiency with precision evaporation?

KINTEK specializes in advanced laboratory equipment, including vacuum evaporation systems designed for energy-efficient concentration and high-purity thin film deposition. Whether you are processing heat-sensitive materials in R&D or manufacturing high-tech components, our solutions are engineered to meet your specific laboratory needs.

Contact us today to discover how our expertise and reliable consumables can optimize your processes and deliver superior results.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate

- What is the difference between PECVD and APCVD? Choose the Right CVD Method for Your Application

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods