In short, a standard autoclave operates at 121°C (250°F), but many are capable of reaching higher temperatures, such as 134°C (273°F). The specific temperature is not arbitrary; it is precisely controlled in conjunction with pressure and time to ensure the complete destruction of all microorganisms, including resilient bacterial spores.

The goal of an autoclave isn't simply to get things hot—it's to use pressurized, saturated steam to achieve sterilization. The temperature is a direct result of the pressure applied, and the most common settings (121°C or 134°C) are industry benchmarks proven to reliably kill all forms of microbial life.

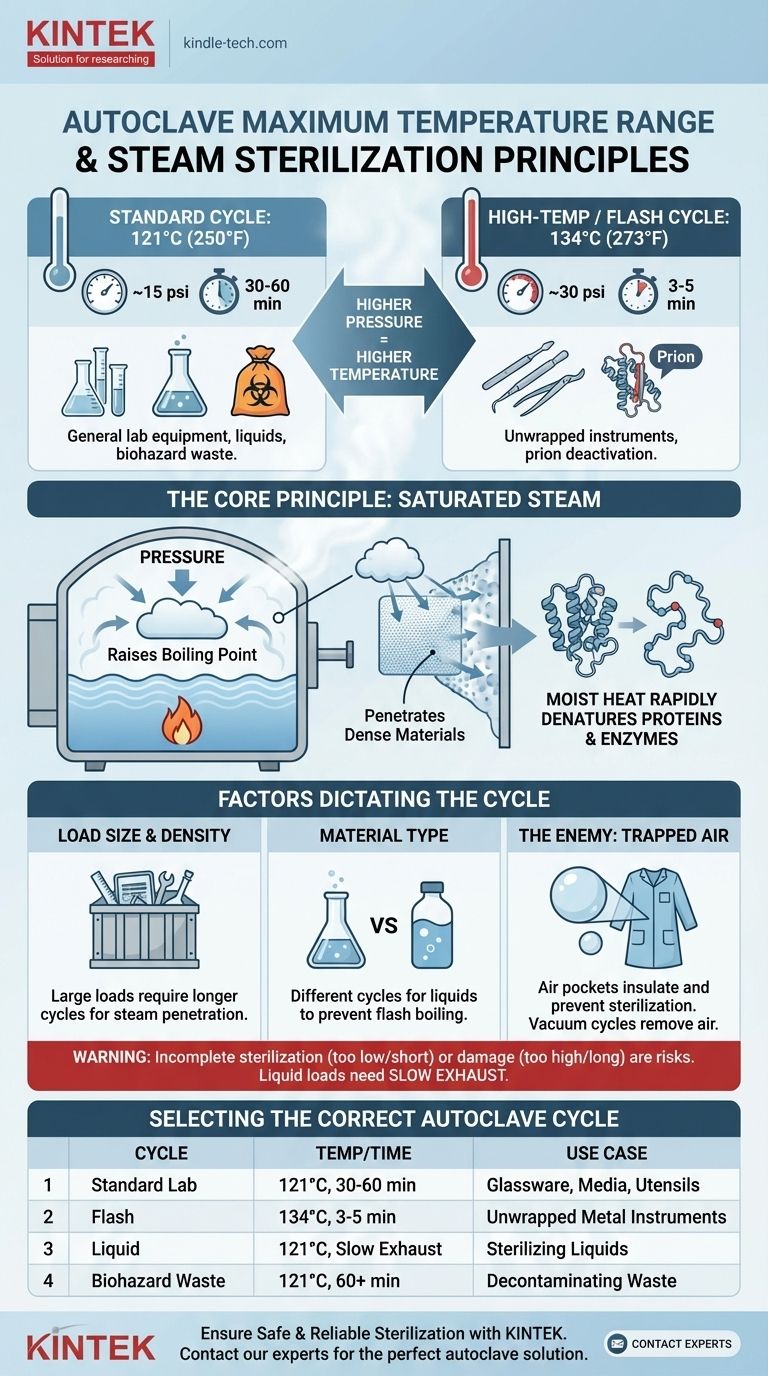

The Core Principle: Sterilization with Saturated Steam

To understand autoclave temperature ranges, you must first understand that dry heat is a very inefficient sterilizer. Autoclaves work by leveraging the immense energy transfer capability of saturated steam under pressure.

Why 121°C is the Benchmark

The most common and widely validated sterilization cycle uses saturated steam at 121°C (250°F) under approximately 15 psi of pressure.

At this temperature and pressure, the moist heat rapidly denatures the essential proteins and enzymes within microorganisms, leading to their death. This cycle typically lasts 30-60 minutes, depending on the load.

The Critical Role of Pressure

Water boils at 100°C (212°F) at normal atmospheric pressure. To achieve the higher temperatures needed for sterilization, the autoclave chamber is pressurized.

This pressure serves two functions: it raises the boiling point of water to the target temperature and forces the steam to penetrate dense materials, ensuring no microbes can hide from the sterilizing heat.

Higher Temperature Cycles: 134°C

Many modern autoclaves also offer a cycle at 134°C (273°F), typically at a pressure of around 30 psi.

This higher temperature allows for much shorter cycle times, often just 3-5 minutes. This is frequently used for unwrapped metal instruments ("flash sterilization") or for destroying prions, which are highly resistant proteins that can cause diseases like Creutzfeldt-Jakob disease.

Factors That Dictate the Cycle

The correct temperature and time are not one-size-fits-all. They depend entirely on what is being sterilized.

Load Size and Density

A large, dense load, such as a full bin of surgical instruments or a large volume of waste, requires a longer cycle. This ensures that steam has enough time to penetrate to the very center of the load and hold it at the target temperature.

Material Type

Different materials require different cycles. Glassware and metal instruments are robust, but liquids and biological media need special consideration. A "liquid cycle" uses a slower cool-down and depressurization phase to prevent the liquids from boiling over violently inside the chamber.

The Enemy: Trapped Air

Air pockets are the primary obstacle to effective steam sterilization. If air is trapped within a container or a porous load (like surgical gowns), it creates an insulating barrier that prevents steam from making direct contact with the surfaces, leading to a sterilization failure. Advanced autoclaves use vacuum cycles to actively remove air before introducing steam.

Understanding the Trade-offs and Risks

Choosing the wrong cycle can have significant consequences, ranging from damaged equipment to critical safety failures.

The Danger of Incomplete Sterilization

Using a temperature that is too low or a cycle that is too short is the most serious risk. This results in items that are not sterile, creating a significant risk of infection or contamination. This is why regular validation with biological indicators is essential.

The Problem with Excessive Heat or Time

More is not always better. Subjecting items to unnecessarily high temperatures or long cycles can cause damage. It can melt certain plastics, degrade the nutrients in laboratory media, and accelerate wear on delicate instruments.

The Hazard of Rapid Depressurization

For liquid loads, venting the pressure too quickly causes the superheated liquid to flash boil. This can lead to shattered glass containers, loss of the liquid, and a hazardous mess inside the autoclave. Always use a dedicated liquid cycle with a slow exhaust.

Selecting the Correct Autoclave Cycle

Your choice must be guided by the material you are sterilizing and the level of sterility assurance you require.

- If your primary focus is general lab equipment (glassware, media, utensils): The standard 121°C cycle for 30-60 minutes is the validated and correct choice.

- If your primary focus is unwrapped metal instruments for immediate use: A 134°C "flash" cycle for 3-5 minutes is an efficient and effective option.

- If your primary focus is sterilizing liquids: You must use a dedicated liquid cycle with a slow exhaust to prevent boil-over, typically at 121°C.

- If your primary focus is decontaminating biohazardous waste: A longer cycle at 121°C (60 minutes or more) is often recommended to ensure full penetration and deactivation.

Matching the autoclave cycle to the load is the absolute key to achieving guaranteed sterility safely and effectively.

Summary Table:

| Common Autoclave Cycle | Temperature | Typical Pressure | Common Use Case |

|---|---|---|---|

| Standard Cycle | 121°C (250°F) | ~15 psi | General lab equipment, liquids, biohazard waste |

| High-Temp/Flash Cycle | 134°C (273°F) | ~30 psi | Unwrapped instruments, prion deactivation |

Ensure your lab's sterilization is safe, effective, and reliable.

Choosing the right autoclave and cycle is critical for both safety and the longevity of your equipment. KINTEK specializes in providing high-quality lab autoclaves and consumables, backed by expert technical support, to meet the precise needs of your laboratory.

Contact our sterilization experts today to find the perfect autoclave solution for your application.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

People Also Ask

- What role does a high-pressure hydrothermal autoclave play in 3D-GO synthesis? Optimize Your Graphene Composites

- How long does it take to autoclave instruments? Get the Full Breakdown for Effective Sterilization

- How long should an autoclave cycle be? A Guide to Optimizing Sterilization Time

- What is the use of autoclave in research? Ensure Sterile Conditions for Valid Scientific Results

- What materials cannot be autoclaved and why? Protect Your Lab Equipment and Ensure Sterility

- What are the uses of autoclave in laboratory equipment? Ensure Sterile Conditions for Your Research

- What method of sterilization is autoclaving? The Definitive Guide to Moist Heat Sterilization

- What is the optimum temperature in an autoclave to achieve sterility? Master the Time, Temperature & Steam Equation