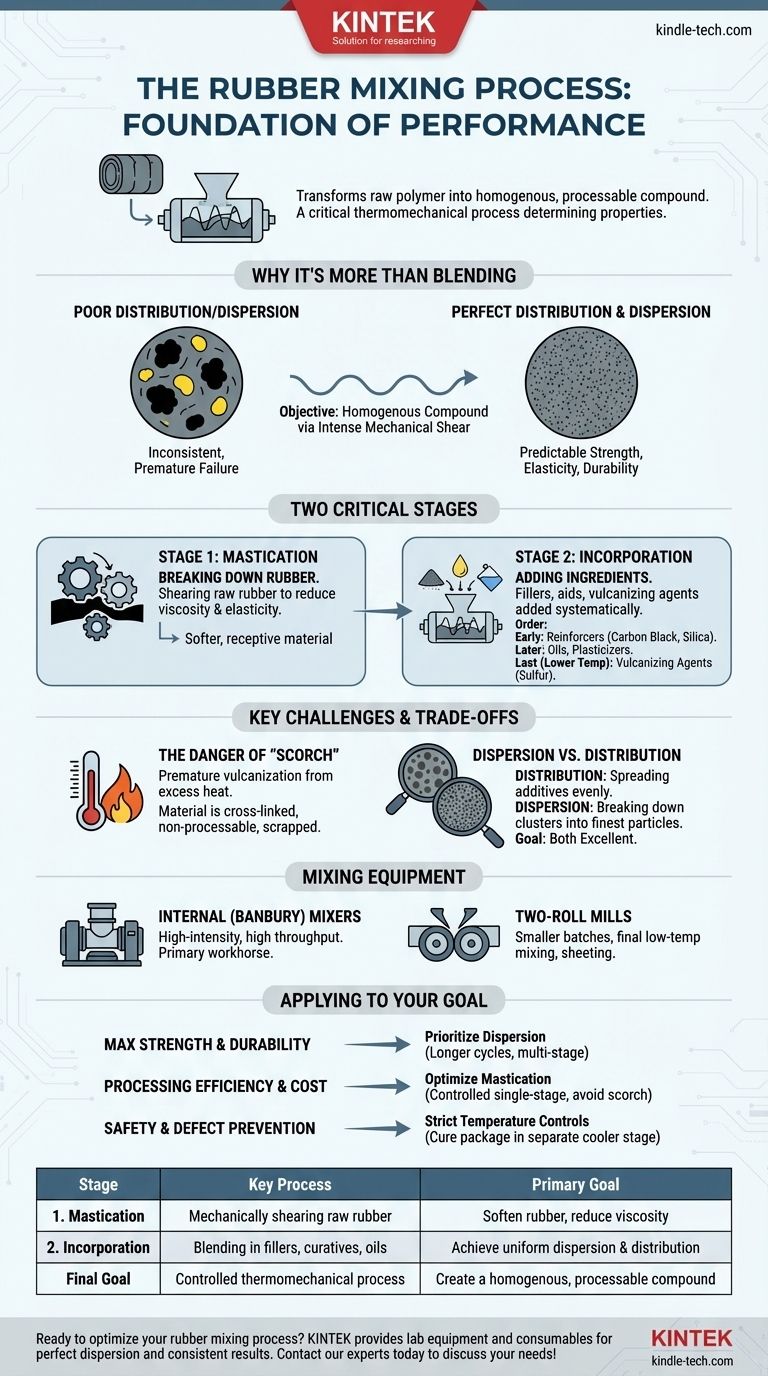

The rubber mixing process is a foundational manufacturing step where raw rubber is mechanically softened and then uniformly blended with a series of additives. This procedure is not merely for blending; it is a critical thermomechanical process that fundamentally determines the physical properties, chemical resistance, and ultimate performance of the vulcanized rubber product.

The core purpose of rubber mixing is to transform raw, unusable polymer into a homogenous, processable compound. This is achieved through two distinct phases: mastication to soften the rubber, followed by the incorporation of additives that dictate the final material's characteristics.

Why Rubber Mixing is More Than Just Blending

The ultimate goal of rubber mixing is to achieve perfect dispersion and distribution of all additives within the rubber matrix. An improperly mixed compound will have inconsistent properties, leading to premature failure.

The Objective: A Homogenous Compound

Think of raw rubber as a dense, tangled mass of long polymer chains. Additives like carbon black or sulfur, if simply stirred in, would remain in clumps.

The mixing process uses intense mechanical shear to disentangle these chains and ensure every particle of every additive is individually surrounded by rubber. This uniformity is what guarantees predictable strength, elasticity, and durability in the final part.

The Two Critical Stages of Rubber Mixing

The entire process can be broken down into two essential, sequential stages. Each stage has a specific goal and directly impacts the quality of the final compound.

Stage 1: Mastication

Mastication is the process of breaking down the rubber itself. Raw natural or synthetic rubber is extremely tough, viscous, and elastic, making it nearly impossible to mix with powders and liquids.

By repeatedly shearing the rubber in a mixer (like a Banbury mixer or a two-roll mill), the long polymer chains are physically broken. This action reduces the rubber's viscosity and elasticity, making it softer, stickier, and more receptive to the addition of other ingredients.

Stage 2: Incorporation

Once the rubber is properly masticated, the incorporation stage begins. This is where fillers, processing aids, antidegradants, and vulcanizing agents are systematically added.

The order of addition is critical. Reinforcing fillers like carbon black or silica are added early to ensure they are fully dispersed. Oils and plasticizers follow. Crucially, the vulcanizing agents (like sulfur and accelerators) are typically added last, in a final, lower-temperature mixing step.

Understanding the Key Challenges and Trade-offs

Success in rubber mixing hinges on carefully managing a few critical variables. Failure to do so can ruin an entire batch of material.

The Danger of "Scorch"

Scorch is the premature initiation of vulcanization (curing) during the mixing process. It is the single most common and costly mixing defect.

Mixing generates immense heat. If the temperature of the compound rises too high after the vulcanizing agents have been added, the rubber will begin to cure inside the mixer. This scorched material is cross-linked, non-processable, and must be scrapped.

Dispersion vs. Distribution

These two terms are not interchangeable and are both vital for success.

- Distribution refers to spreading the additives evenly throughout the rubber batch.

- Dispersion refers to breaking down clusters or agglomerates of additives into their finest possible particles.

A batch can have good distribution of poorly dispersed filler clumps, which will result in a weak final product. The goal is always excellent distribution and excellent dispersion.

The Role of Mixing Equipment

Two primary types of equipment are used:

- Internal (Banbury) Mixers: These high-intensity, enclosed mixers are the workhorses of the industry, used for mastication and a majority of the incorporation stage. They offer high throughput and excellent control.

- Two-Roll Mills: These open mills are used for smaller batches, final mixing (especially for adding curatives at a controlled temperature), or for forming the mixed rubber into sheets.

Applying This to Your Compounding Goal

The priorities of your mixing cycle will change depending on the desired outcome for the final rubber compound.

- If your primary focus is maximum strength and durability: Prioritize achieving the highest possible degree of dispersion for your reinforcing fillers, which may require a longer mixing cycle or a multi-stage process.

- If your primary focus is processing efficiency and cost: Optimize mastication time and use a highly-controlled, single-stage internal mixing cycle जहां भी संभव हो (wherever possible), ensuring you stay below the scorch temperature.

- If your primary focus is safety and defect prevention: Implement strict temperature controls and always add the cure package in a separate, cooler, and final mixing stage.

Mastering the mixing process is the first and most critical step in engineering a rubber compound that performs exactly as intended.

Summary Table:

| Stage | Key Process | Primary Goal |

|---|---|---|

| 1. Mastication | Mechanically shearing raw rubber | Soften rubber, reduce viscosity for mixing |

| 2. Incorporation | Blending in fillers, curatives, oils | Achieve uniform dispersion & distribution |

| Final Goal | Controlled thermomechanical process | Create a homogenous, processable compound |

Ready to optimize your rubber mixing process? KINTEK specializes in lab equipment and consumables for rubber compounding. Whether you are developing a new formulation or troubleshooting a mixing issue, our expertise and products can help you achieve perfect dispersion, prevent scorch, and ensure consistent, high-quality results. Contact our experts today to discuss your specific laboratory needs!

Visual Guide

Related Products

- Lab Internal Rubber Mixer Rubber Kneader Machine for Mixing and Kneading

- Rubber Vulcanizer Vulcanizing Machine Plate Vulcanizing Press for Lab

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

People Also Ask

- What are the advantages of coextrusion? Achieve Multi-Material Efficiency and Superior Performance

- What are the ingredients used in rubber compounding? A Guide to the Essential Formula

- What are extruded examples? Discover the Process Behind Everyday Objects

- Why is the dynamic mixing mode necessary for high-strength HPE-CSPE? Unlock Superior Elastomer Performance

- What machine makes molding? Injection Molding Machines for Mass Production

- What is a two roll mill for rubber compounding? A Foundational Tool for Polymer Processing

- What are the three types of rolling mills? A Guide to Boosting Your Metal Production Efficiency

- What is the injection molding process step by step? A Guide to High-Volume Manufacturing