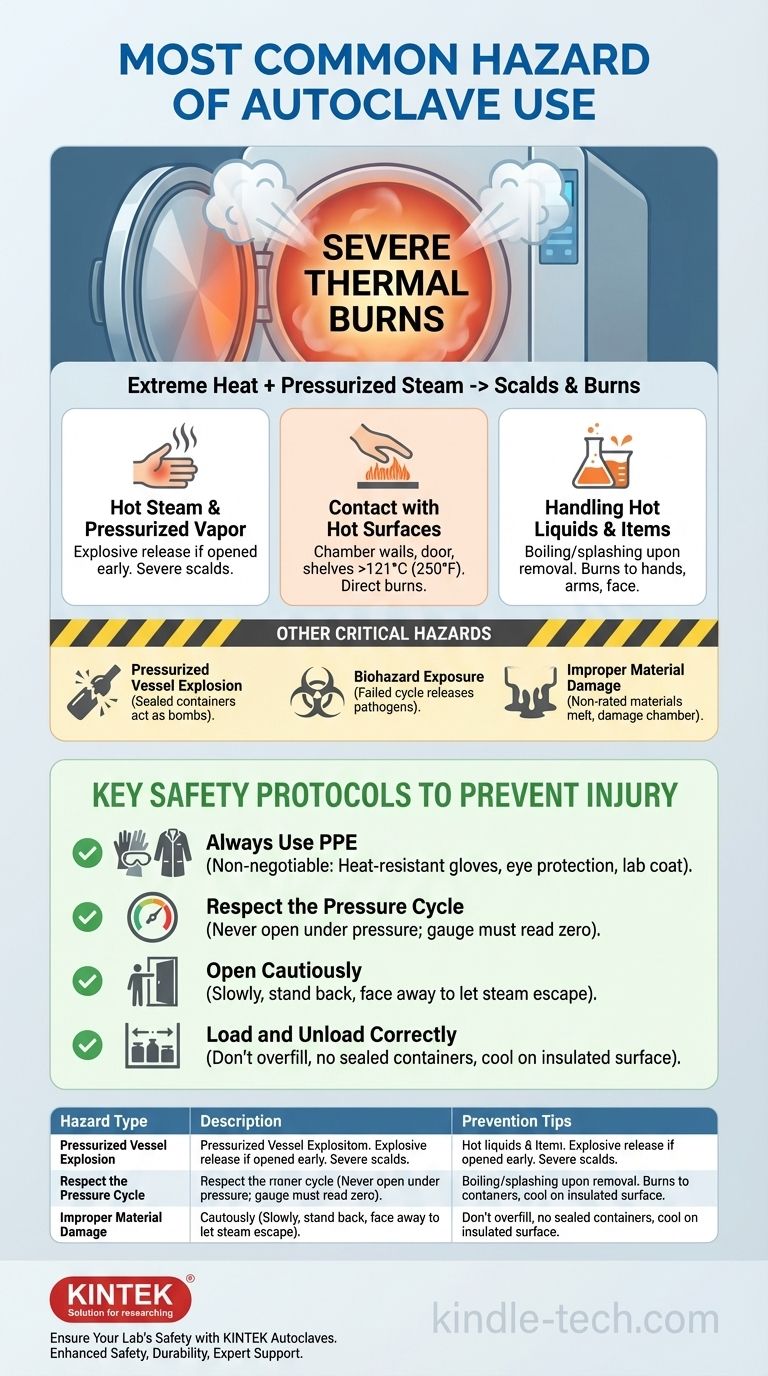

The single most common hazard of using an autoclave is severe thermal burns. These injuries result from the extreme heat and pressurized steam fundamental to the autoclave's operation. Burns can occur from contact with escaping steam, hot liquids, the inner chamber surfaces, or the sterilized items themselves upon removal.

An autoclave is a high-pressure, high-temperature sterilizer. While incredibly effective, its core function creates inherent risks of severe burns, scalding, and even explosions if safety protocols are not rigorously followed.

The Primary Hazard: Severe Burns and Scalds

The combination of heat and pressure makes burns the most immediate and frequent danger for any autoclave operator. These injuries manifest in several ways.

Hot Steam and Pressurized Vapor

When an autoclave cycle finishes, the chamber is still filled with superheated, pressurized steam. Opening the door before the pressure has fully returned to zero can cause a violent and explosive release of this steam, leading to severe scalds.

Contact with Hot Surfaces

The internal chamber walls, door, and shelving of an autoclave reach temperatures well over 121°C (250°F). Any direct skin contact, even momentary, will cause a serious burn. This risk is highest during the unloading process.

Handling Hot Liquids and Items

Items removed from the autoclave are dangerously hot and can remain so for a significant time. Glassware and especially liquids pose a high risk, as they can boil over or splash when moved, causing severe burns to the hands, arms, and face.

Other Critical Hazards to Understand

While burns are the most common risk, operators must be aware of other potential dangers that can lead to serious injury or equipment failure.

Pressurized Vessel Explosions

This is a less common but catastrophic failure. Placing liquids in a completely sealed container and autoclaving it effectively creates a bomb. As the liquid heats, it expands and builds immense pressure with no means of escape, which can cause the container to explode and shatter the autoclave door.

Biohazard Exposure

Autoclaves are often used to decontaminate biological waste. If a sterilization cycle fails due to improper loading or a machine malfunction, operators may be exposed to live, infectious pathogens when they open the chamber.

Improper Material Damage

Using materials not rated for an autoclave can cause significant problems. Common plastics like polyethylene will melt, creating fumes and damaging the autoclave's chamber and drain. Carbon steel instruments can be damaged by the high moisture content.

Key Safety Protocols to Prevent Injury

Adhering to strict operational procedures is the only way to mitigate the inherent risks of an autoclave. Ignoring these steps is the primary cause of accidents.

Always Use Personal Protective Equipment (PPE)

This is non-negotiable. When loading and especially unloading an autoclave, you must wear a lab coat, eye protection, and heat-resistant gloves that provide full coverage of the hands and forearms.

Respect the Pressure Cycle

Never attempt to open an autoclave door while it is under pressure. Modern autoclaves have safety locks, but you must always verify that the chamber pressure gauge reads zero before unlatching the door.

Open the Door Cautiously

Once the pressure is at zero, open the door slowly and only a small amount at first. Stand back and to the side of the door, keeping your face and body away from the opening. This allows residual steam and heat to escape safely before you fully open it.

Load and Unload Correctly

Never overfill the chamber; this ensures proper steam penetration. Arrange items so they are not touching, and never place items in sealed containers. When unloading, remove items slowly and carefully, placing them on an insulated surface to cool.

Making the Right Choice for Your Task

Your specific application dictates which safety precautions are most critical.

- If your primary focus is routine equipment sterilization: Prioritize wearing full PPE during unloading and allowing a sufficient cool-down period before handling any items.

- If your primary focus is sterilizing liquids: Ensure you are using vented caps or covering flasks with aluminum foil, never sealing them, and using a slow-exhaust liquid cycle to prevent boil-over.

- If your primary focus is decontaminating biohazardous waste: In addition to all personal safety measures, you must validate your cycles with biological indicators to confirm complete sterilization and prevent exposure to pathogens.

Ultimately, safety in autoclave use is an active process, not a passive one; your diligence is the most critical safety feature.

Summary Table:

| Hazard Type | Description | Prevention Tips |

|---|---|---|

| Severe Thermal Burns | Contact with hot steam, surfaces, or items post-sterilization. | Always wear full PPE (heat-resistant gloves, lab coat, eye protection). |

| Pressurized Vessel Explosion | Sealed containers can explode due to pressure buildup. | Never autoclave liquids in sealed containers; use vented caps or foil. |

| Biohazard Exposure | Risk of pathogen exposure from failed sterilization cycles. | Validate cycles with biological indicators; ensure proper loading. |

| Improper Material Damage | Melting plastics or damaged instruments from incorrect use. | Use only autoclave-safe materials; avoid carbon steel in moist cycles. |

Ensure Your Lab's Safety with KINTEK Autoclaves

Protect your team from the most common autoclave hazards with reliable, safety-focused equipment from KINTEK. We specialize in high-performance lab autoclaves designed with advanced safety features to prevent thermal burns, pressure explosions, and biohazard risks. Our products are ideal for laboratories sterilizing equipment, liquids, or biohazardous waste.

Why Choose KINTEK?

- Enhanced Safety: Built-in pressure locks, clear cycle indicators, and robust construction minimize risks.

- Durability: Engineered for long-term, dependable operation in demanding lab environments.

- Expert Support: Get guidance on proper usage, maintenance, and safety protocols from our specialists.

Don’t compromise on safety—contact KINTEK today to find the perfect autoclave solution for your laboratory’s needs!

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

People Also Ask

- What are the advantages of autoclave? Achieve Unmatched Sterilization Efficiency and Reliability

- What is the function of a Teflon-lined stainless steel autoclave in rGO/TiO2 synthesis? Key Role in Nanocomposites

- How often should an autoclave be serviced? A Risk-Based Guide to Sterilization Compliance

- What is the temperature range of an autoclave? From 121°C to 134°C for Optimal Sterilization

- What is the lifespan of an autoclave? Maximize Your Equipment's Lifespan with Expert Care

- Why is a 24-hour hydrothermal treatment in an autoclave necessary for BMO nanosheets? Unlock Superior Photocatalysis

- How often do autoclaves need to be serviced? A Guide to Risk-Based Maintenance Schedules

- Why is a high-strength sealed reaction bottle or autoclave necessary during the ammonia pre-treatment of biomass?