For most industrial applications, the most efficient means of separating solids from a liquid via gravity is through a process called sedimentation, enhanced by coagulation and flocculation, and carried out in a clarifier or thickener. While simple settling in a tank works for large, heavy particles, it is fundamentally inefficient for the fine, suspended solids common in many processes. True efficiency is achieved by chemically aggregating these fine particles into larger masses that settle rapidly and predictably.

The core challenge of gravity separation isn't gravity itself, but the nature of the particles. The most "efficient" method is rarely about the vessel alone; it's about actively manipulating the particles to make them settle dramatically faster than they would naturally.

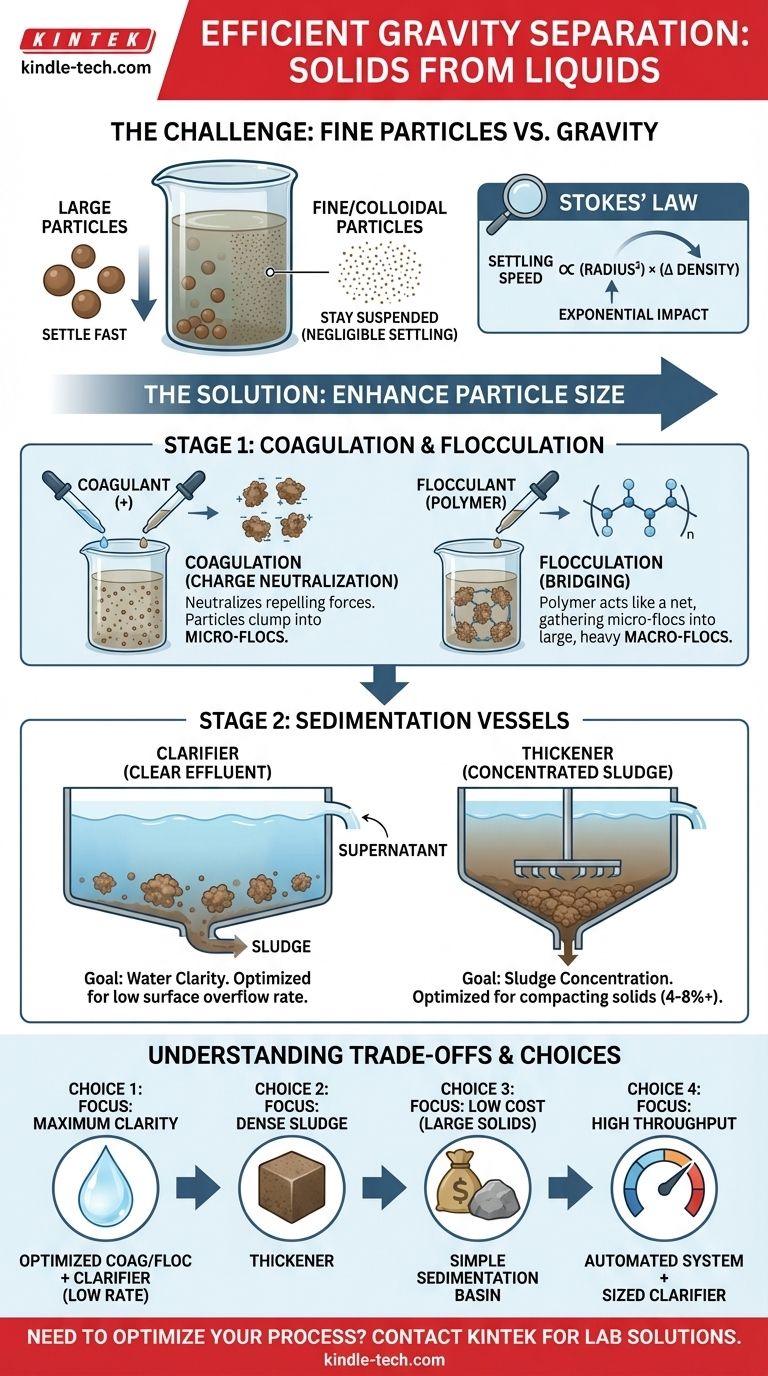

The Core Principle: Why Small Particles Don't Settle

To understand efficiency in separation, you must first understand why it so often fails. The behavior of a particle in a fluid is governed by a fundamental principle.

The Power of Stokes' Law

Stokes' Law is a physical equation that describes the settling velocity of a small sphere in a fluid. The key takeaway is that settling speed is directly proportional to the square of the particle's radius and the difference in density between the solid and the liquid.

This means if you double a particle's radius, its settling rate increases by a factor of four. This exponential relationship is the single most important factor in gravity separation.

The Problem with Colloidal Solids

Many industrial wastewaters or process streams contain colloidal solids—particles so fine (typically less than 1 micrometer) that they are held in suspension indefinitely.

Their microscopic size means their settling velocity according to Stokes' Law is practically zero. Furthermore, they often carry a negative surface charge, causing them to repel each other and preventing them from aggregating and settling naturally.

Key Techniques for Gravity Separation

Based on these principles, different methods are used depending on the particle characteristics and the desired outcome.

Stage 1: Coagulation & Flocculation

This two-step chemical pretreatment is the key to making gravity separation efficient for fine particles.

First, a coagulant (like aluminum sulfate or ferric chloride) is added. Its positive charge neutralizes the negative charge on the colloidal particles, allowing them to stop repelling each other and begin clumping together into micro-flocs.

Next, a flocculant (typically a long-chain polymer) is introduced. This polymer acts like a net, gathering the micro-flocs into large, heavy macro-flocs that look like snowflakes. These large flocs have a dramatically higher settling velocity.

Stage 2: Sedimentation Vessels

Once particles are large enough to settle, they are removed in a purpose-built vessel.

A clarifier is a large tank designed to receive a continuous flow of liquid, provide a calm environment for the flocs to settle, and allow the clear liquid (supernatant) to overflow from the top. Its primary goal is producing a very clear effluent.

A thickener is a specific type of clarifier, often with a steeper conical bottom and a slow-moving rake mechanism. Its primary goal is not just to clarify the liquid, but to produce a highly concentrated solid sludge (underflow) at the bottom for dewatering or disposal.

Understanding the Trade-offs

Choosing the "most efficient" method requires defining your goals, as there are inherent compromises.

Speed vs. Clarity

A key design parameter for a clarifier is its surface overflow rate (flow rate divided by surface area). A low overflow rate means the liquid moves upwards very slowly, giving even smaller particles time to settle.

This creates a direct trade-off: processing a higher flow rate (speed) in a given clarifier will decrease the residence time and likely reduce the clarity of the overflowing water.

Capital Cost vs. Operational Cost

Building a massive sedimentation basin to achieve a low overflow rate without chemicals is a high capital expense.

Conversely, using an aggressive coagulation and flocculation program can allow you to use a much smaller, cheaper clarifier. However, this introduces a continuous operational expense for the chemicals.

Sludge Concentration vs. Vessel Design

A standard clarifier might produce a sludge with 1-2% solids. A thickener, with its specialized design and rake action, can compact that sludge to 4-8% solids or more.

This reduces the volume of sludge that needs to be handled downstream, but thickeners often require more residence time and represent a more complex piece of equipment.

Making the Right Choice for Your Goal

Efficiency is not a single value; it's the optimal balance of speed, cost, and results for your specific process.

- If your primary focus is maximum water clarity: Prioritize an optimized coagulation/flocculation program combined with a clarifier designed for a low surface overflow rate.

- If your primary focus is producing a dense, low-volume sludge: Your best choice is a thickener, which is specifically engineered to compact settled solids.

- If your primary focus is separating large, heavy solids at low cost: A simple sedimentation basin or decanting tank may be sufficient, forgoing the expense of chemicals and complex equipment.

- If your primary focus is high-throughput processing: A well-designed system combining automated chemical dosing with a properly sized clarifier will deliver the most effective and reliable results.

Ultimately, achieving efficient gravity separation is a matter of actively engineering particle behavior to overcome the limitations of nature.

Summary Table:

| Method | Best For | Key Advantage | Consideration |

|---|---|---|---|

| Coagulation/Flocculation | Fine, colloidal solids | Dramatically increases settling speed | Requires chemical operational expense |

| Clarifier | Producing clear effluent | Optimized for water clarity | Lower surface overflow rate needed |

| Thickener | Concentrated sludge production | Compacts solids to 4-8%+ density | Higher capital cost and complexity |

| Simple Sedimentation | Large, heavy particles | Low cost, no chemicals | Inefficient for fine particles |

Need to Optimize Your Solid-Liquid Separation Process?

Choosing the right gravity separation method is critical for your lab's efficiency and cost-effectiveness. KINTEK specializes in providing the precise lab equipment and consumables needed to implement these techniques—from coagulation chemicals to sedimentation vessels.

Let our experts help you select the ideal solution to achieve superior clarity, higher throughput, or denser sludge, tailored to your specific laboratory needs.

Contact KINTEK today for a consultation and enhance your separation process!

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer for Microwave Digestion Tank

- Laboratory Test Sieves and Sieving Machines

- Custom PTFE Teflon Parts Manufacturer for PTFE Containers

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

People Also Ask

- What are the advantages and disadvantages of the sintering process? Achieve Strong, Complex Parts with High-Temp Materials

- How does biomass compare to other renewable sources? Unlocking On-Demand Power for Grid Stability

- What are the disadvantages of rotary vane vacuum pumps? Understand the Oil-Related Trade-offs

- What are the driving forces of sintering? Understanding the Thermodynamics for Better Materials

- What are the advantages of RF sputtering over DC sputtering? Achieve Superior Thin Films for Advanced Applications

- What is the use of drying oven in laboratory? Achieve Uniform Heat for Drying, Sterilizing, and Curing

- What is the minimum temperature for sintering? It Depends on Your Material's Melting Point

- What is the HIP process in ceramics? Achieve Full Density and Superior Mechanical Properties