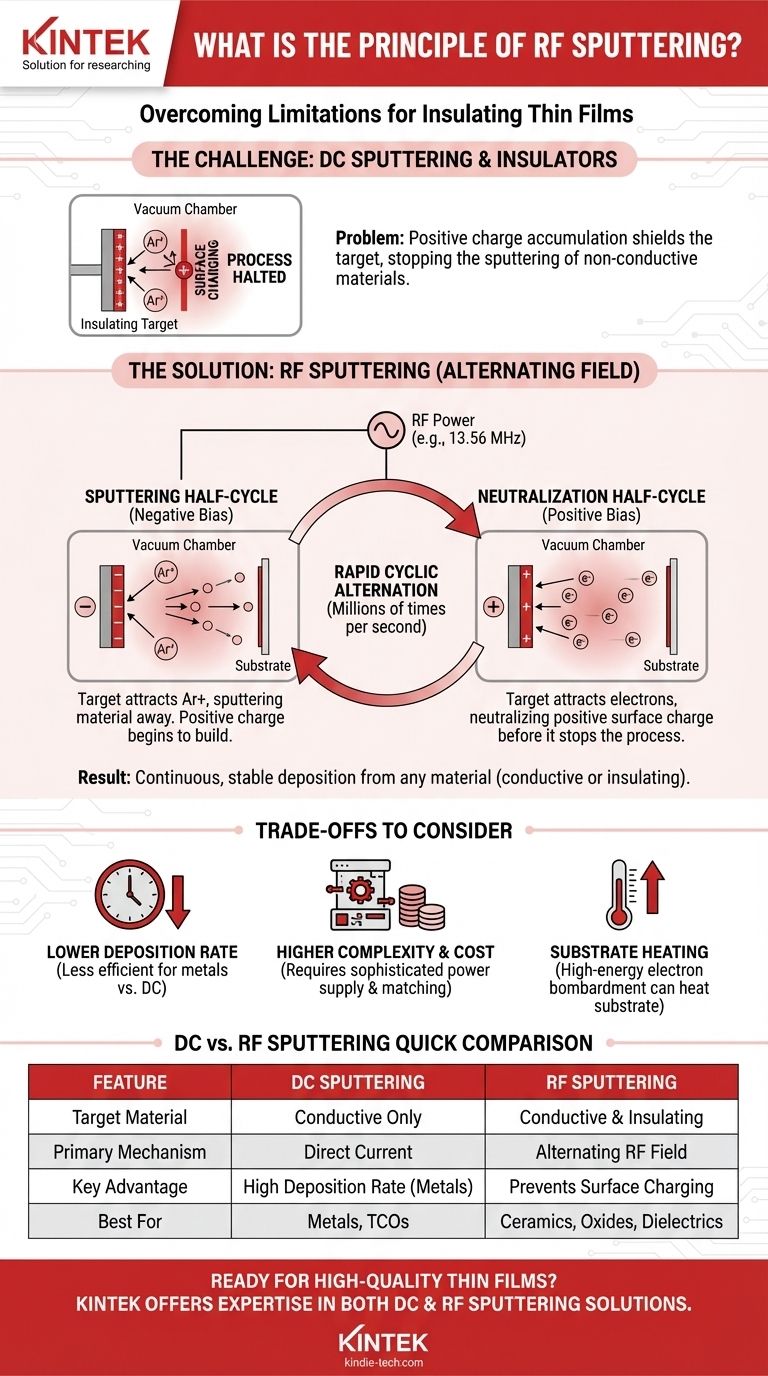

In principle, RF sputtering is a thin-film deposition technique that uses an alternating, radio-frequency electric field to create a plasma. This AC field overcomes the primary limitation of standard DC sputtering, allowing for the consistent deposition of thin films from electrically insulating (dielectric) materials, not just conductive ones. It achieves this by cyclically neutralizing charge build-up on the target's surface.

The core problem with sputtering insulating materials is that they accumulate a positive surface charge that repels the very ions needed for deposition. RF sputtering solves this by rapidly alternating the electric field, using one part of the cycle to sputter and the other to attract electrons that neutralize this charge.

The Foundation: How Basic Sputtering Works

To understand the innovation of RF sputtering, you must first grasp the principle of sputtering in general. It is a physical vapor deposition (PVD) process that occurs inside a vacuum chamber.

Creating the Plasma Environment

The process begins by introducing an inert gas, typically Argon, into a low-pressure vacuum chamber. An electric field is then applied, which energizes the gas and strips electrons from the Argon atoms, creating a glowing, ionized gas known as plasma.

The Bombardment Process

This plasma consists of positive Argon ions (Ar+) and free electrons. A target, made of the material you wish to deposit, is given a strong negative electrical potential, causing it to act as a cathode. The positive Argon ions are accelerated by this field and bombard the surface of the target at high energy.

Ejection and Deposition

The force of these ion impacts is strong enough to knock out, or "sputter," individual atoms from the target material. These ejected atoms travel through the vacuum chamber and condense as a uniform thin film on a substrate (like a silicon wafer) placed nearby.

The Challenge with Insulating Materials

The basic sputtering method described above is known as DC sputtering, as it uses a direct current power supply. It is highly effective for conductive materials but fails completely for insulators.

The Failure of DC Sputtering

When using a DC source with a non-conductive target (like a ceramic or an oxide), the process quickly stops. The target material, being an insulator, cannot dissipate the electrical charge from the constant stream of positive Argon ions bombarding its surface.

Surface Charging and Its Consequence

This results in a rapid build-up of positive charge on the target's face. This phenomenon, known as surface charging, creates a positive potential that repels any further incoming positive Argon ions, effectively shielding the target and halting the sputtering process almost immediately.

The RF Sputtering Solution: Alternating the Field

RF sputtering was developed specifically to solve this surface charging problem. It replaces the DC power supply with an AC power source operating at radio frequencies (typically 13.56 MHz).

The Sputtering Half-Cycle

During the negative portion of the AC cycle, the target is negatively biased. This attracts the positive Argon ions from the plasma, which bombard the surface and sputter material away, just as in DC sputtering. A positive charge begins to accumulate on the insulating surface.

The Neutralization Half-Cycle

However, before this charge can build up enough to stop the process, the field reverses. During the brief positive portion of the AC cycle, the target becomes positively biased. It now strongly attracts the highly mobile, negatively charged electrons from the plasma.

A flood of these electrons strikes the target surface, neutralizing the positive charge that accumulated during the previous half-cycle. The target is effectively "reset" for the next sputtering phase.

The Result: Continuous, Stable Deposition

Because this cycle repeats millions of times per second, the target's surface potential never becomes large enough to repel the Argon ions. This allows for continuous, stable sputtering of atoms from any type of material, whether it is an electrical conductor or an insulator.

Understanding the Trade-offs

While RF sputtering is more versatile, it is important to understand its compromises compared to the simpler DC method.

Deposition Rate

For conductive materials, RF sputtering generally has a lower deposition rate than DC sputtering. The time spent in the neutralization half-cycle is time not spent sputtering material, making the process less efficient for metals.

System Complexity and Cost

RF systems require more sophisticated power supplies and an impedance-matching network to efficiently transfer power to the plasma. This makes RF sputtering equipment more complex and expensive than its DC counterparts.

Substrate Heating

The high-energy electron bombardment during the neutralization cycle can contribute to significant heating of the substrate. This may be a concern when depositing films onto temperature-sensitive materials or substrates.

Making the Right Choice for Your Goal

Your choice between DC and RF sputtering should be determined entirely by the electrical properties of your target material.

- If your target material is electrically conductive (e.g., metals, transparent conductive oxides): DC sputtering is the more efficient and cost-effective choice due to its higher deposition rates and simpler equipment.

- If your target material is an insulator or dielectric (e.g., ceramics, silicon dioxide, aluminum oxide): RF sputtering is the essential and correct method, as it is specifically designed to prevent the surface charging that halts the DC process.

- If your primary goal is system versatility: An RF sputtering system provides the most flexibility, as it can successfully deposit films from both conductive and insulating targets.

By understanding the fundamental role of the alternating field, you can confidently select the sputtering technique that directly addresses the properties of your target material.

Summary Table:

| Feature | DC Sputtering | RF Sputtering |

|---|---|---|

| Target Material | Conductive only | Conductive & Insulating |

| Primary Mechanism | Direct Current | Alternating Radio Frequency (e.g., 13.56 MHz) |

| Key Advantage | High deposition rate for metals | Prevents surface charging on insulators |

| Best For | Metals, TCOs | Ceramics, oxides, dielectrics |

Ready to deposit high-quality thin films from any material?

Whether your project requires the efficiency of DC sputtering for metals or the versatility of RF sputtering for insulating ceramics, KINTEK has the expertise and equipment to meet your laboratory's needs. Our range of sputtering systems is designed to deliver precise, reliable results for your most challenging applications.

Contact our experts today to discuss how we can enhance your thin-film deposition process!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Platinum Auxiliary Electrode for Laboratory Use

- Platinum Sheet Electrode for Laboratory and Industrial Applications

People Also Ask

- What is thin film deposition using CVD? The Ultimate Guide to High-Performance Coatings

- What is the chemical method of graphene synthesis? Scaling Up High-Quality Production

- Which substrates are considered superior for the CVD of graphene? Choosing Copper vs. Nickel for High-Quality Growth

- What are the methods for carbon nanotubes synthesis? A Guide to Arc-Discharge, Laser Ablation, and CVD

- What is the Chemical Vapor Deposition (CVD) method for diamond synthesis? Unlock Molecular Precision in Lab Growth

- What are the uses of CVD? From Microchips to Diamond Coatings

- What is ALD for semiconductor process? The Key to Atomic-Level Precision in Chip Manufacturing

- What are the benefits of diamond-like carbon coating? Boost Component Life with Extreme Hardness & Low Friction