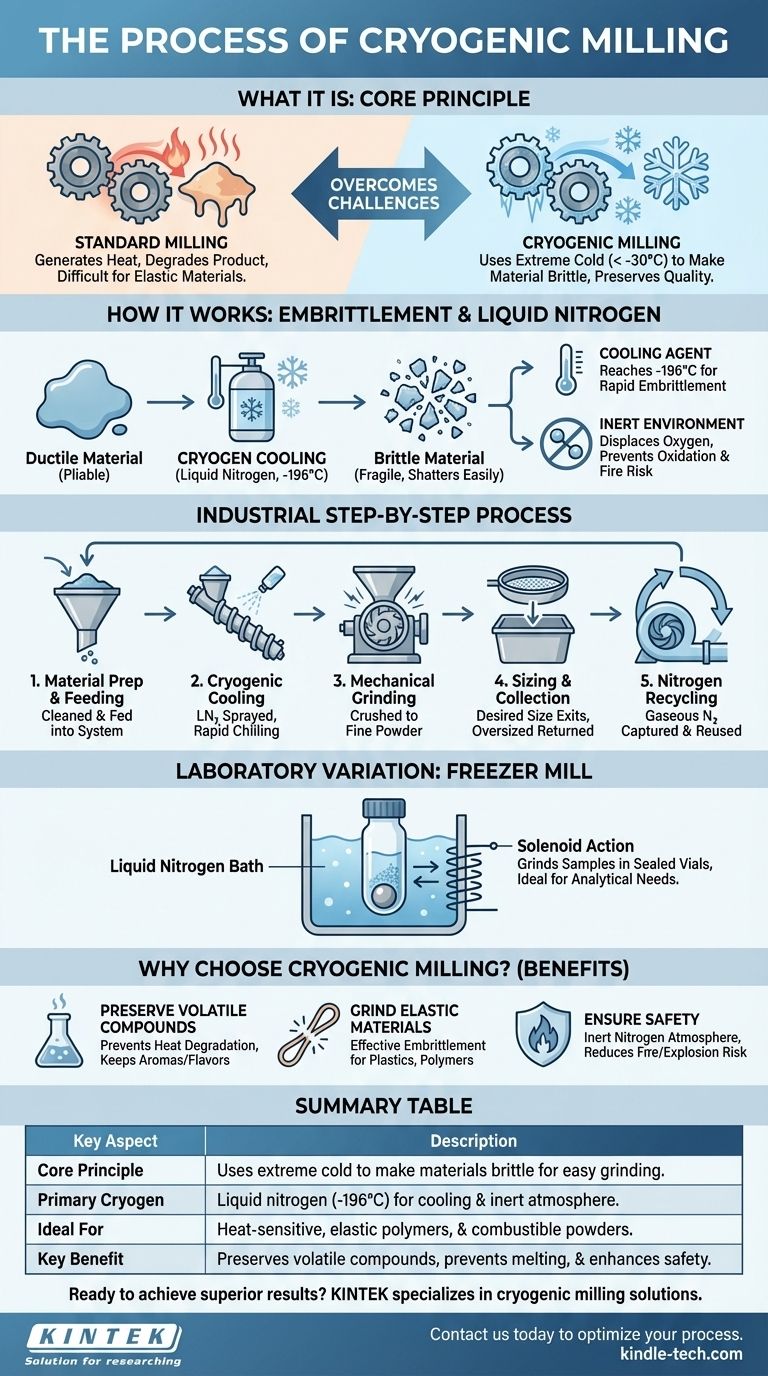

In essence, cryogenic milling is a size reduction process that uses extreme cold to make tough, elastic, or heat-sensitive materials brittle enough to be easily ground. This is achieved by chilling the material, typically with liquid nitrogen, to temperatures below -30°C (-22°F) before or during the mechanical grinding operation. This deep chill fundamentally changes the material's properties, allowing for efficient pulverization.

Where standard milling generates heat that can degrade or melt a product, cryogenic milling uses extreme cold to its advantage. It is a process designed not just for size reduction, but for the preservation of a material's essential quality, composition, and safety.

How Does Cryogenic Milling Work? The Core Principle

The Problem with Standard Milling

Standard grinding relies on mechanical force, which generates significant friction and heat. For many materials, this is a destructive process that can cause melting, smearing, or the loss of volatile compounds like aromas and flavors.

Elastic materials, such as plastics and polymers, are also notoriously difficult to grind at ambient temperatures because they simply deform under impact rather than fracturing.

The Cryogenic Solution: Embrittlement

Cryogenic milling overcomes these challenges by inducing embrittlement. By rapidly cooling a material with a cryogen, its structure changes from ductile (pliable) to brittle (fragile).

Once brittle, the material shatters easily upon impact, allowing the mill to produce a fine, uniform powder with much less energy.

The Role of Liquid Nitrogen

Liquid nitrogen is the most common cryogen used in this process. It provides two key functions simultaneously.

First, it is the cooling agent, reaching temperatures as low as -196°C (-321°F), which ensures rapid and thorough embrittlement.

Second, as the liquid nitrogen vaporizes, it displaces oxygen, creating an inert environment. This prevents oxidation and dramatically reduces the risk of fire or dust explosion, a critical safety feature when milling fine, combustible powders.

The Step-by-Step Process of an Industrial Grinder

A typical industrial cryogenic grinding system operates as a continuous, closed-loop process.

1. Material Preparation and Feeding

The raw material is first cleaned and fed into a hopper. From there, it moves onto a vibratory feeder, which ensures a consistent and controlled flow into the grinding system.

2. Cryogenic Cooling

The material is then transported via a helical screw conveyor. At this stage, liquid nitrogen is sprayed directly onto the material, chilling it rapidly as it moves toward the mill.

3. Mechanical Grinding

The now-brittle material enters the grinding chamber. It is crushed and shattered into fine particles by mechanical action, often between a series of high-speed studs and cones.

4. Sizing and Collection

The ground product exits the mill and passes through a sieve. This screen ensures that only particles of the desired size move on, while oversized particles are returned to the mill for further grinding. The final product is collected in a bin.

5. Nitrogen Recycling

The gaseous nitrogen that vaporized during the cooling stage is captured by a centrifugal blower. It is then recycled back into the system to pre-cool the incoming material, improving the overall efficiency of the process.

A Common Variation: The Freezer Mill

For smaller, laboratory-scale applications, a "freezer mill" is often used. This is a specific type of cryogenic mill ideal for preparing temperature-sensitive samples for analysis.

Designed for Analytical Samples

Instead of a large, continuous system, a freezer mill grinds samples in individual sealed vials.

How It Works: Solenoid Action

The vial, containing the sample and a steel grinding medium, is immersed in liquid nitrogen. A powerful solenoid then moves the grinding medium back and forth magnetically inside the vial, pulverizing the sample while it remains at cryogenic temperatures. The only moving part is the grinder inside the vial, reducing mechanical stress on the equipment.

Making the Right Choice for Your Goal

Cryogenic milling is a specialized solution for specific challenges. Its value is highest when standard methods fail to deliver the required quality or are simply ineffective.

- If your primary focus is preserving volatile compounds (like flavors or aromas): Cryogenic milling is essential to prevent heat from degrading your product's inherent quality and chemical profile.

- If your primary focus is grinding tough, elastic materials (like plastics or polymers): This process is the most effective way to achieve fine, uniform particles by inducing embrittlement where other methods fail.

- If your primary focus is safety with combustible dusts: The inert nitrogen atmosphere created during cryogenic milling significantly reduces the risk of oxidation and fire.

By fundamentally altering a material's physical state, cryogenic milling provides a level of control and quality unattainable through conventional methods.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Principle | Uses extreme cold (cryogenics) to make materials brittle for easy grinding. |

| Primary Cryogen | Liquid nitrogen (-196°C / -321°F) for cooling and creating an inert atmosphere. |

| Ideal For | Heat-sensitive materials, elastic polymers, and combustible powders. |

| Key Benefit | Preserves volatile compounds, prevents melting, and enhances safety. |

Ready to achieve superior results with your toughest materials?

KINTEK specializes in providing advanced laboratory equipment, including cryogenic milling solutions, to help you process heat-sensitive, elastic, or combustible materials with precision and safety. Our expertise ensures you get the fine, uniform powders you need while preserving your product's essential qualities.

Contact us today to discuss how our lab equipment can optimize your process and deliver the quality you demand. Get in touch now!

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- High Energy Vibratory Laboratory Ball Mill Double Tank Type

- High Energy Planetary Ball Mill for Laboratory Horizontal Tank Type Milling Machine

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the specific utility of cryomilling for Cantor alloys? Unlock High-Strength Nanocrystalline Structures

- What is the process of cryo milling? Achieve Nanoscale Powder & Superior Material Properties

- What food is cryogenic grinding? The Ultimate Guide to Preserving Flavor & Aroma

- What process advantages are offered by integrating a cryogenic cooling device during HPT? Achieve Ultimate Grain Refinement

- What is the temperature of cryogenic grinding? Achieve Superior Particle Size & Preserve Heat-Sensitive Materials

- What is the cryogenic grinding process? Achieve Superior Quality and Efficiency for Sensitive Materials

- What is cryogenic grinding of herbs? Preserve Flavor and Potency with Sub-Zero Milling

- What is cryogenic grinding process? Achieve Fine Powder from Heat-Sensitive Materials