Glass reactors are versatile equipment used in various industries for chemical reactions, distillation, and other processes. They come in a wide range of sizes to accommodate different scales of operations, from small-scale laboratory research to large-scale industrial production. The size of a glass reactor typically ranges from 50 milliliters (mL) to 200 liters (L), with common sizes including 5L, 10L, 20L, 50L, and 100L. The choice of size depends on the specific application, reaction volume, and operational requirements. Smaller reactors, such as 5L or mini-lab reactors, are ideal for small-scale experiments, while larger reactors are used for industrial-scale production. The material, typically borosilicate glass, ensures durability, chemical resistance, and transparency for monitoring reactions.

Key Points Explained:

-

Size Range of Glass Reactors:

- Glass reactors are available in a wide range of sizes, from as small as 50 milliliters (mL) to as large as 200 liters (L).

- Common sizes include 5L, 10L, 20L, 50L, and 100L, catering to both laboratory and industrial needs.

- Smaller reactors (e.g., 5L) are ideal for small-scale reactions, while larger reactors (e.g., 100L or 200L) are used for industrial-scale production.

-

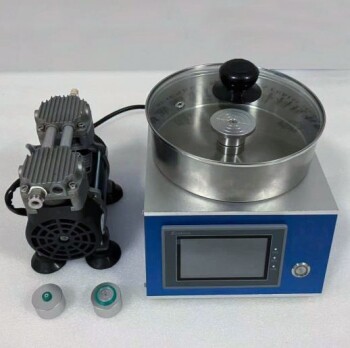

Mini-Lab Glass Reactors:

- Mini-lab glass reactors are designed for small-scale reactions and are equipped with features like digital display units, mechanical sealing, and structural stability.

- These reactors are suitable for processes such as distillation, condensation, stirring, extraction, and separation.

- Their compact size and precision make them ideal for research and development in laboratories.

-

Material and Durability:

- Glass reactors are typically made of borosilicate glass, which is known for its chemical inertness, high temperature resistance, and durability.

- The material is corrosion-resistant, making it suitable for use with a wide range of chemicals.

- The transparency of the glass allows for real-time observation of the reaction process, which is crucial for monitoring and control.

-

Applications Across Industries:

- Glass reactors are used in various industries, including chemicals, pharmaceuticals, dyes, pesticides, petroleum, and food additives.

- Smaller reactors are often used in batch processes for research and small-scale production.

- Larger reactors are employed in large-scale chemical production plants where high volumes of materials are processed.

-

Heating and Structural Features:

- Glass reactors are designed to withstand high temperatures and pressures, making them suitable for a wide range of chemical reactions.

- Heating methods include steam, electric heaters, and high-temperature heat transfer oil.

- Structural features such as jackets, half pipes, and fan coils enhance the reactor's efficiency and versatility.

-

Advantages of Glass Reactors:

- No Pollution: Glass reactors are hygienic and do not contaminate the reaction mixture.

- Fast Heating: The design allows for rapid heating, which is essential for many chemical processes.

- Transparency: The ability to observe the reaction in real-time is a significant advantage for process control and optimization.

-

Choosing the Right Size:

- The choice of reactor size depends on the scale of the operation and the volume of the reaction.

- For laboratory use, smaller reactors (e.g., 5L or 10L) are typically sufficient.

- For industrial applications, larger reactors (e.g., 50L, 100L, or 200L) are necessary to handle higher volumes of materials.

In summary, the size of a glass reactor is a critical factor that determines its suitability for specific applications. Whether for small-scale laboratory research or large-scale industrial production, glass reactors offer a range of sizes and features to meet diverse operational needs. The choice of size, combined with the reactor's material and structural features, ensures efficient and reliable performance across various industries.

Summary Table:

| Size Range | Common Sizes | Applications |

|---|---|---|

| 50 mL - 200 L | 5L, 10L, 20L, 50L, 100L | Small-scale experiments to industrial production |

| Mini-Lab Reactors | 5L or smaller | Research, distillation, extraction, and small-scale reactions |

| Material | Borosilicate glass | Chemical resistance, durability, and transparency |

| Industries | Chemicals, pharmaceuticals, food additives, petroleum | Batch processes, large-scale production |

Need help selecting the right glass reactor for your needs? Contact our experts today!