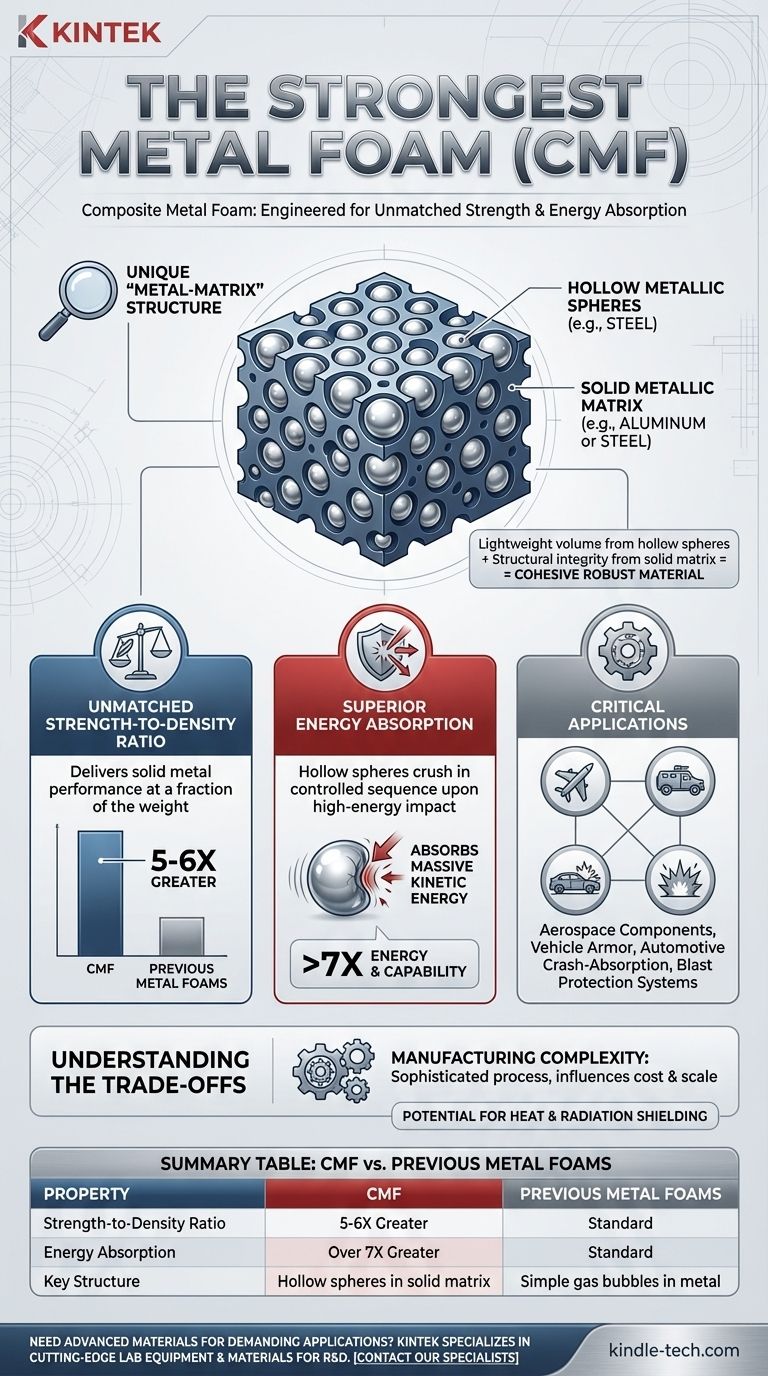

The strongest metal foam currently developed is known as Composite Metal Foam, or CMF. This advanced material is not simply metal with trapped gas bubbles; it is an engineered composite that provides a strength-to-density ratio 5 to 6 times greater than previous metal foams. It also demonstrates over 7 times the energy absorption capability.

The exceptional performance of Composite Metal Foam comes from its unique structure: hollow metallic spheres suspended within a solid metallic matrix. This design combines the benefits of low density with the profound strength and energy-absorbing potential of its engineered architecture.

How Composite Metal Foam Achieves Its Strength

The term "strong" can mean many things in material science. CMF excels across several critical metrics, not just one. Its superiority is a direct result of its internal structure.

A Unique "Metal-Matrix" Composition

At its core, CMF is made by embedding hollow spheres of one metal, such as steel, into a solid metallic matrix of another, like aluminum or steel.

The spheres provide lightweight volume, while the solid matrix provides structural integrity and binds the spheres together into a cohesive, robust whole.

Unmatched Strength-to-Density Ratio

This structure allows CMF to deliver the performance of solid metal at a fraction of the weight.

The internal voids created by the hollow spheres drastically reduce its density. However, the well-bonded matrix ensures that forces are distributed efficiently across the material, preventing structural failure under high loads.

Superior Energy Absorption

This is arguably CMF's most impressive characteristic. When a high-energy impact occurs, the hollow spheres are designed to crush and deform in a controlled sequence.

This process absorbs a massive amount of kinetic energy, far more than a solid piece of metal which would simply dent or fracture. This makes it exceptionally effective at mitigating blasts, ballistic impacts, and crash forces.

Understanding the Trade-offs and Applications

While CMF possesses revolutionary properties, it is an advanced material with specific considerations. Understanding its context is key to leveraging its advantages.

Manufacturing Complexity

Producing CMF is a more sophisticated process than casting a solid block of metal or creating a simple foam. This complexity can influence cost and the scale of production for certain applications.

Potential Applications

The unique properties of CMF make it a candidate material for some of the most demanding engineering challenges.

Its primary applications are in sectors where high strength, low weight, and energy absorption are critical. This includes aerospace components, vehicle armor, automotive crash-absorption structures, and blast protection systems.

Making the Right Choice for Your Goal

Evaluating Composite Metal Foam requires aligning its specific strengths with your primary engineering objective.

- If your primary focus is lightweight structural integrity: CMF is a leading candidate due to its exceptional strength-to-density ratio, offering stiffness and resilience without a significant weight penalty.

- If your primary focus is impact, blast, or crash protection: CMF's energy absorption capability is its most defining and revolutionary feature, making it superior to nearly any other foam material.

- If your primary focus is heat or radiation shielding: The internal structure of CMF has also been shown to be highly effective at blocking thermal energy and certain forms of radiation, opening another avenue of application.

Ultimately, Composite Metal Foam represents a significant step forward in material science, redefining what is possible when strength and weight are critical design factors.

Summary Table:

| Property | Composite Metal Foam (CMF) | Previous Metal Foams |

|---|---|---|

| Strength-to-Density Ratio | 5-6 times greater | Standard |

| Energy Absorption | Over 7 times greater | Standard |

| Key Structure | Hollow metallic spheres in a solid matrix | Simple gas bubbles in metal |

Need advanced materials for your demanding applications? KINTEK specializes in providing cutting-edge lab equipment and materials for research and development. If you're exploring the potential of high-performance materials like Composite Metal Foam for aerospace, automotive, or protective systems, our expertise can support your innovation. Contact our specialists today to discuss how we can help you achieve your material science goals.

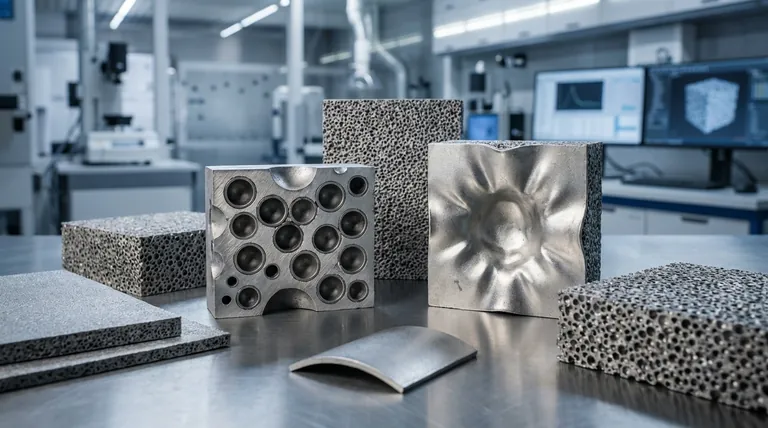

Visual Guide

Related Products

- Copper Foam

- High Purity Zinc Foil for Battery Lab Applications

- High Purity Gold Platinum Copper Iron Metal Sheets

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

People Also Ask

- What are the downsides of using metal foam? Understanding the Trade-offs of a Specialist Material

- How do you transfer graphene from copper? A Step-by-Step Guide to Preserving Pristine Quality

- How do you make copper foam? A Step-by-Step Guide to Creating Porous Metal Structures

- Is metal foam expensive? Unpacking the High Cost of Advanced Materials

- What are the proper storage conditions for nickel and copper foam? A Guide to Preserving Performance

- What are the characteristics of copper foam? Unlock High-Performance Thermal and Electrical Solutions

- Is copper foam safe? Discover the facts about its antimicrobial and cooling benefits

- What are the common applications of copper foam? A Guide to Its High-Performance Uses