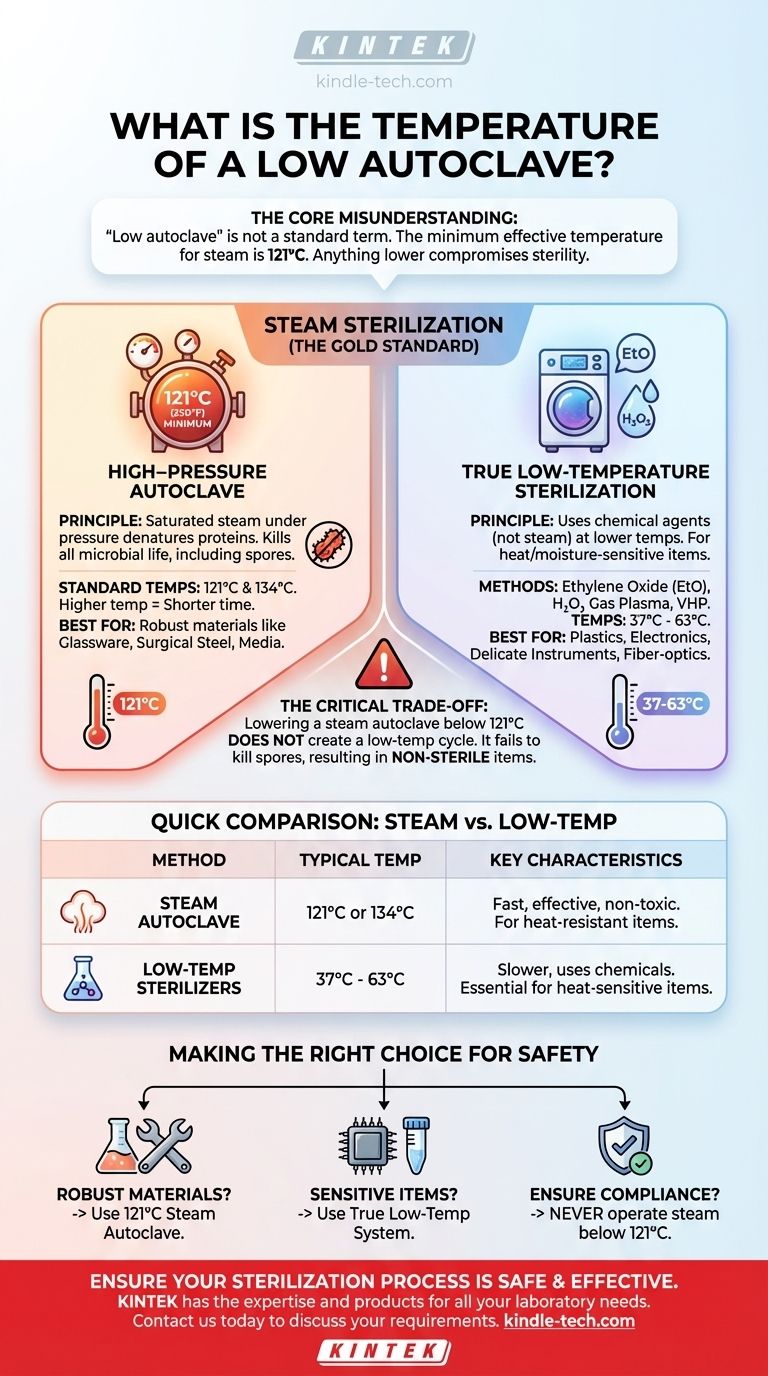

In professional and laboratory settings, the term "low autoclave" is not standard. The lowest commonly used and validated temperature for a steam autoclave is 121°C (250°F). Attempting to run a cycle below this temperature compromises the entire sterilization process.

The core issue is a misunderstanding of terminology. The question isn't about a "low autoclave," but about the difference between the minimum effective temperature for steam sterilization (121°C) and the separate category of true low-temperature sterilizers designed for heat-sensitive materials.

Deconstructing Sterilization: The Role of Temperature

To understand why 121°C is the critical threshold, we must first look at the principles of steam sterilization. It is not just about heat; it is about heat delivered by saturated steam under pressure.

The Principle of Steam Sterilization

An autoclave works by using high-pressure steam to transfer thermal energy to the items inside, effectively denaturing proteins and killing all microbial life, including resilient bacterial spores.

Pressure is essential because it allows water to remain in its gaseous steam state at temperatures well above its normal boiling point of 100°C.

The Standard Temperature Thresholds

The two universally recognized temperature standards for steam autoclaving are:

- 121°C (250°F)

- 134°C (273°F)

The choice between them depends on the materials being sterilized and the required speed of the cycle. Higher temperatures require shorter exposure times.

Why 121°C is the Minimum

This temperature was not chosen arbitrarily. 121°C is the scientifically validated minimum temperature required to reliably kill the most heat-resistant organisms known, specifically the spores of the bacterium Geobacillus stearothermophilus.

A typical cycle at this temperature requires at least 15-20 minutes of exposure time once the target temperature has been reached throughout the entire load. This combination of time, temperature, and saturated steam ensures a high level of sterility assurance.

What a True "Low-Temperature" Method Is

When professionals talk about "low-temperature sterilization," they are not referring to a steam autoclave at all. They are referring to entirely different technologies used for items that cannot withstand the high heat and moisture of an autoclave.

When Steam Autoclaves Are Not an Option

The combination of intense heat and moisture will destroy or damage many common medical and laboratory items. This includes most plastics, electronics, power tools, cameras, and delicate fiber-optic instruments.

Introducing Low-Temperature Sterilization Systems

For these sensitive items, dedicated low-temperature sterilizers are used. These systems operate at much lower temperatures and use chemical agents instead of steam.

Common methods include:

- Ethylene Oxide (EtO): A toxic gas used at temperatures between 37°C and 63°C.

- Hydrogen Peroxide (H₂O₂) Gas Plasma: Uses vaporized hydrogen peroxide and an electrical field to create a sterilizing plasma, typically around 50°C.

- Vaporized Hydrogen Peroxide (VHP): Circulates heated hydrogen peroxide vapor at low pressure.

These methods are effective but are fundamentally different from the steam-based process of an autoclave.

Understanding the Trade-offs

Choosing the wrong method or using incorrect parameters is not a matter of preference; it is a critical safety failure.

The Risk of Incorrect Parameters

Simply lowering the temperature of a steam autoclave below 121°C will not work. You will fail to kill heat-resistant spores, resulting in an item that is clean but not sterile. This creates a significant risk of infection or contamination.

Steam Autoclave: Pros and Cons

The primary advantage of steam autoclaving is that it is fast, highly effective, non-toxic, and inexpensive. Its major limitation is its incompatibility with heat and moisture-sensitive materials.

Low-Temperature Sterilizers: Pros and Cons

These systems are essential for sterilizing delicate and expensive equipment. However, the cycles are often much longer, the equipment is more expensive, and the processes may involve hazardous chemicals that require careful handling and aeration.

Making the Right Choice for Your Goal

Selecting the correct process is fundamental to achieving sterility. Your decision should be based entirely on the material you are processing and the established scientific standards.

- If your primary focus is sterilizing robust materials like glassware, surgical steel, or media: The standard 121°C steam autoclave cycle is your most reliable and efficient choice.

- If your primary focus is sterilizing heat-sensitive items like plastics, electronics, or certain polymers: You must use a true low-temperature sterilization system, such as one based on hydrogen peroxide or ethylene oxide.

- If your primary focus is ensuring safety and compliance: Never operate a steam autoclave below its validated 121°C threshold, as this directly violates sterilization principles and produces a non-sterile product.

Understanding the fundamental principles of each sterilization method is the key to ensuring both safety and efficacy in your work.

Summary Table:

| Sterilization Method | Typical Temperature | Key Characteristics |

|---|---|---|

| Steam Autoclave | 121°C (250°F) or 134°C (273°F) | Uses saturated steam under pressure; ideal for robust materials like glass and steel. |

| Low-Temperature Sterilizers | 37°C - 63°C | Uses chemical agents (e.g., H₂O₂, EtO); essential for heat-sensitive items like plastics and electronics. |

Ensure Your Sterilization Process is Safe and Effective

Choosing the right equipment is critical for laboratory safety and compliance. Whether you need a reliable steam autoclave for standard materials or a specialized low-temperature system for sensitive devices, KINTEK has the expertise and products to meet your laboratory's unique needs.

Contact us today via our contact form to discuss your specific requirements. Our specialists will help you select the perfect sterilizer to ensure efficacy, protect your valuable equipment, and maintain the highest standards of safety.

Visual Guide

Related Products

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

People Also Ask

- What is the most common machine used to sterilize medical supplies? The Definitive Guide to Autoclaves

- What are the limitations of an autoclave? Understanding Material Compatibility and Safety Constraints

- Why is a Teflon-lined high-pressure autoclave required for Mo-Ti-N catalyst synthesis? Ensure Purity and Precision

- Why is proper maintenance and cleaning of the autoclave important? Ensure Sterilization Efficacy and Safety

- Why is autoclaving the most effective? Harness the Power of Pressurized Steam for Absolute Sterility

- What is the temperature range of an autoclave? From 121°C to 134°C for Optimal Sterilization

- Why is chemical sterilization sometimes used as an alternative to autoclaving? To Safely Sterilize Heat-Sensitive Equipment

- How does an autoclave apply pressure? The Science of Steam Sterilization Explained