To be precise, the term "hardenable" most commonly refers to steel and iron alloys that can undergo a specific phase transformation. However, a broader range of non-ferrous metals, including certain alloys of aluminum, titanium, nickel, and copper, can also have their hardness and strength significantly increased through different heat treatment processes.

The key determinant of whether a metal is hardenable is its specific alloy composition. For steels, the presence of sufficient carbon is critical, while for other metals, the ability to form strengthening precipitates within the metallic structure is what enables hardening.

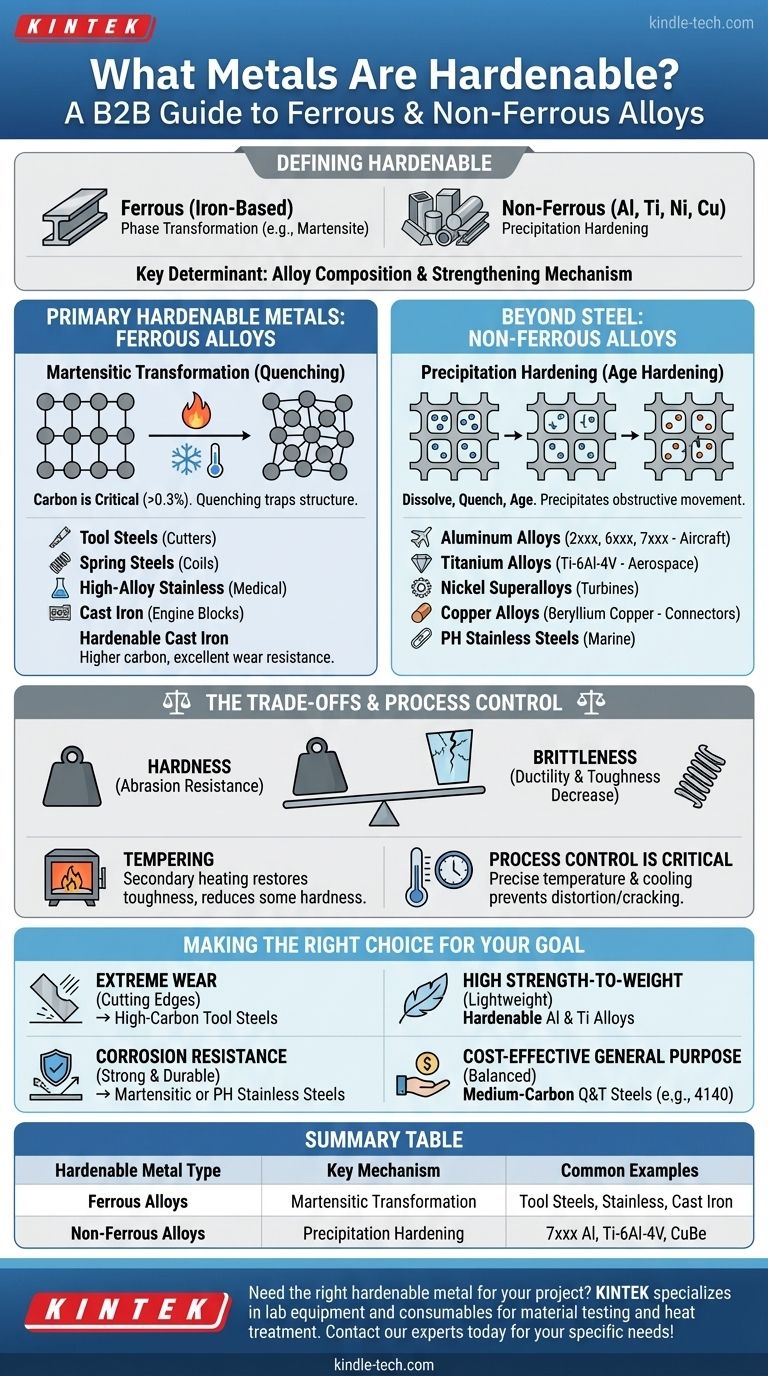

The Primary Hardenable Metals: Ferrous Alloys

The most common and widely understood hardenable materials are ferrous alloys, meaning they are based on iron. Their ability to be hardened is a direct result of carbon content and the unique way iron's crystal structure changes with temperature.

The Role of Carbon in Steel

Carbon is the single most important element for hardening steel. When steel with sufficient carbon (typically above 0.3%) is heated to a high temperature, the carbon atoms dissolve into the iron's crystal structure.

Rapid cooling, known as quenching, traps this structure in a very hard, brittle state called martensite. This transformation is the foundation of traditional steel hardening.

Common Hardenable Steel Families

Practically all significant steel alloys can be hardened to some degree. This includes a vast range of materials engineered for specific applications.

These categories include tool steels, spring steels, high-alloy stainless steels, quenched and tempered steels, and alloys used for anti-friction bearings.

Hardenable Cast Iron

Beyond steel, many cast iron alloys are also hardenable. These materials, which have a much higher carbon content than steel, can be heat-treated to achieve exceptional hardness and wear resistance, making them suitable for heavy machinery and engine components.

Beyond Steel: Other Hardenable Alloys

While steel is the classic example, several important non-ferrous metals can also be hardened. These materials use a different mechanism that does not rely on a martensitic transformation.

Precipitation Hardening (Age Hardening)

For most hardenable non-ferrous alloys, the mechanism is precipitation hardening, also known as age hardening.

This process involves heating the metal to dissolve alloying elements, quenching it to trap them in a "supersaturated" solution, and then "aging" it at a lower temperature to allow microscopic particles (precipitates) to form. These precipitates obstruct movement within the metal's crystal structure, increasing its strength and hardness.

Hardenable Non-Ferrous Examples

Alloys that rely on this mechanism include many high-performance materials:

- Aluminum Alloys: Specifically the 2xxx, 6xxx, and 7xxx series.

- Titanium Alloys: Such as the widely used Ti-6Al-4V.

- Nickel-based Superalloys: Including Inconel and Waspaloy.

- Copper Alloys: Notably Beryllium Copper (CuBe).

- Certain Stainless Steels: Known as precipitation-hardening (PH) stainless steels.

The Inevitable Trade-offs of Hardening

Increasing a metal's hardness is not a "free lunch." It is a process of exchanging one material property for another, and understanding these trade-offs is critical for successful engineering.

Hardness vs. Brittleness

The most fundamental trade-off is that as hardness increases, ductility and toughness decrease.

A fully hardened, un-tempered piece of steel is often as brittle as glass. It can withstand immense abrasion but will shatter under a sharp impact.

The Necessity of Tempering

Because of this brittleness, hardened steel parts are almost always tempered. This is a secondary, lower-temperature heat treatment that reduces some hardness to restore a crucial amount of toughness, making the final component both strong and durable.

Process Control is Critical

Hardening processes require precise control over temperature and cooling rates. Improper execution can lead to part distortion, cracking, or inconsistent mechanical properties, compromising the integrity of the final product.

Making the Right Choice for Your Goal

Selecting a hardenable material depends entirely on the specific demands of your application.

- If your primary focus is extreme wear resistance and cutting edges: High-carbon tool steels are specifically designed for maximum hardness and edge retention.

- If your primary focus is a high strength-to-weight ratio: Hardenable aluminum and titanium alloys provide excellent strength without the weight penalty of steel.

- If your primary focus is corrosion resistance with good strength: Martensitic or precipitation-hardening (PH) stainless steels are the ideal choice.

- If your primary focus is a cost-effective, general-purpose strong part: Medium-carbon, quenched and tempered steels (like 4140) offer the best all-around balance of strength, toughness, and cost.

Ultimately, choosing a hardenable metal is about targeting a specific set of mechanical properties to meet a real-world challenge.

Summary Table:

| Hardenable Metal Type | Key Mechanism | Common Examples |

|---|---|---|

| Ferrous Alloys | Martensitic Transformation | Tool Steels, Stainless Steels, Cast Iron |

| Non-Ferrous Alloys | Precipitation Hardening | 7xxx Series Aluminum, Ti-6Al-4V, Beryllium Copper |

Need the right hardenable metal for your project? KINTEK specializes in lab equipment and consumables for material testing and heat treatment processes. Our expertise helps you select and process the ideal alloys for maximum strength, wear resistance, or corrosion performance. Contact our experts today to discuss your specific laboratory or production needs!

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What affects the melting point of a substance? Uncover the Key Factors & Forces

- What is a muffle furnace used for in a lab? Achieve Clean, High-Temperature Processing

- What are the 4 types of heat treatment steel undergoes? Master Annealing, Normalizing, Hardening & Tempering

- Is the sintering process hazardous? Identifying Key Risks and Safety Protocols

- What is the difference between sintering and vitrification? Key Thermal Process Distinctions