While autoclaving is the gold standard, it is far from the only method for achieving sterilization. The primary alternatives rely on different mechanisms, such as high-temperature dry air, reactive chemical gases, or high-energy radiation, each suited for materials that cannot withstand the high heat and moisture of pressurized steam.

The most effective sterilization method is entirely dependent on the material being sterilized. While steam autoclaving is reliable for many items, its limitations with heat-sensitive plastics, electronics, and moisture-intolerant substances necessitate the use of dry heat, chemical, or radiation-based alternatives.

Why Look Beyond the Autoclave?

Steam sterilization, performed in an autoclave, uses pressurized steam to denature proteins and kill microorganisms. As noted in standard protocols, this typically involves reaching 121°C, making it highly effective for items like surgical tools and laboratory glassware.

However, this combination of high heat and moisture makes autoclaving unsuitable for many modern materials.

The Challenge of Heat-Sensitive Materials

Many medical devices, diagnostic tools, and laboratory instruments are made from polymers (plastics) or contain sensitive electronic components. These materials can melt, warp, or be destroyed at the temperatures required for steam sterilization.

The Problem with Moisture

Certain materials, such as powders, oils, or anhydrous substances, are compromised by the presence of moisture. Using a steam autoclave would render them useless. Similarly, devices with complex, sealed internal channels may not be effectively sterilized if steam cannot penetrate them.

Key Alternatives to Steam Sterilization

To address these limitations, several other robust sterilization methods are widely used in medical, pharmaceutical, and industrial settings. Each has a distinct mechanism of action and application.

Dry Heat Sterilization

This is the simplest alternative, conceptually similar to a conventional oven. It uses high-temperature, dry air to kill microorganisms through oxidation, which effectively burns them from the inside out.

Because dry air is less efficient at transferring heat than steam, this method requires higher temperatures and longer exposure times. A typical cycle might be 170°C (340°F) for one hour or 160°C (320°F) for two hours.

It is the preferred method for moisture-sensitive items like glassware, metal instruments (that might corrode with steam), oils, and powders.

Chemical Sterilization (Low-Temperature Gas)

For items that are sensitive to both heat and moisture, chemical gases are an excellent solution. These methods operate at much lower temperatures (typically 30-60°C).

The most common agent is Ethylene Oxide (EtO). EtO is a highly penetrating gas that sterilizes by disrupting the DNA of microorganisms, preventing them from reproducing. It is ideal for a vast range of materials, including plastics, electronics, and complex medical devices with long lumens.

Another prominent method is Vaporized Hydrogen Peroxide (VHP). VHP sterilizes by generating free radicals that destroy microorganisms. It has a faster cycle time and leaves non-toxic byproducts (water and oxygen), but it has lower penetration capability than EtO.

Radiation Sterilization

This is a high-throughput, industrial-scale process that uses high-energy radiation to destroy microbial DNA, similar to chemical methods but without the use of gas. It is a "cold" process, meaning it generates very little heat.

Gamma radiation, using Cobalt-60 as a source, is the most common form. Its high penetration power makes it perfect for sterilizing large batches of fully packaged products, such as syringes, sutures, and single-use medical kits.

Electron beam (E-beam) radiation is another option. It has a much faster cycle time than gamma but offers less penetration, making it suitable for lower-density, uniformly packaged products.

Understanding the Trade-offs

No single method is universally superior; the choice involves a careful balance of material compatibility, cost, and safety considerations.

Material Compatibility is Paramount

The first question must always be: what will my material tolerate? Heat-stable, moisture-tolerant items are suited for an autoclave. Heat-stable but moisture-sensitive items require dry heat. Heat- and moisture-sensitive items demand chemical or radiation methods.

Penetration vs. Surface Sterilization

Steam (autoclave) and EtO gas are excellent at penetrating complex shapes, wrapped kits, and long tubes. VHP is more of a surface sterilant with limited penetration. Gamma radiation penetrates deeply through final packaging, while E-beam is less penetrating.

Safety and Residuals

Steam sterilization is the safest, leaving only sterile water. EtO, by contrast, is a toxic and carcinogenic gas that requires a lengthy aeration period after the cycle to remove harmful residuals from the product. VHP breaks down into harmless water and oxygen. Radiation leaves no residuals but requires massive concrete shielding for safe operation.

Making the Right Choice for Your Goal

Base your decision on the specific requirements of the item you need to sterilize.

- If your primary focus is sterilizing robust glassware, surgical steel, or media: The autoclave remains the most efficient and reliable method.

- If your primary focus is sterilizing heat-sensitive plastics, electronics, or complex medical devices: Chemical sterilization with Ethylene Oxide or VHP is the industry standard.

- If your primary focus is sterilizing oils, powders, or moisture-sensitive metal instruments: Dry heat sterilization is the most appropriate and accessible choice.

- If your primary focus is large-scale, terminal sterilization of pre-packaged disposables: Gamma or E-beam radiation is the unmatched industrial solution.

Ultimately, understanding the properties of your materials will guide you to the correct and most effective sterilization technology.

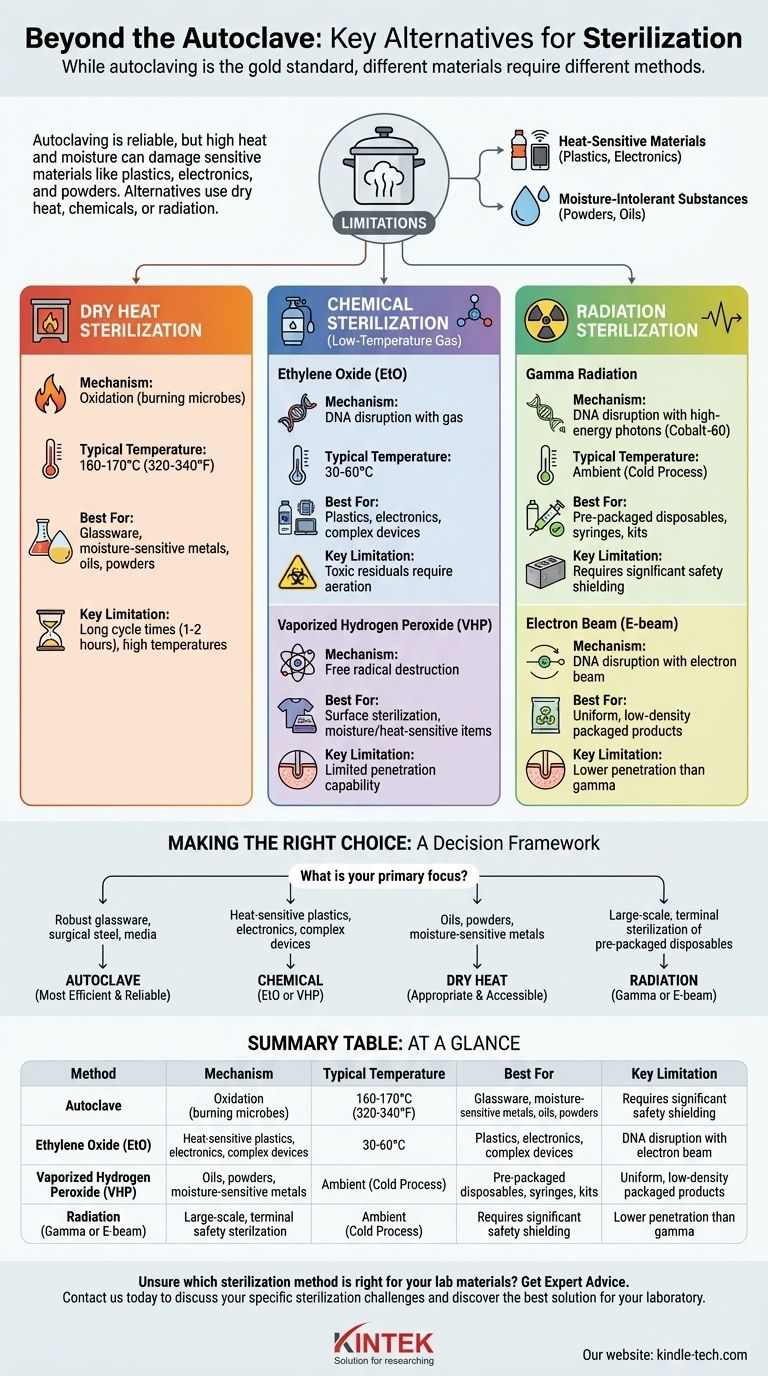

Summary Table:

| Method | Mechanism | Typical Temperature | Best For | Key Limitation |

|---|---|---|---|---|

| Dry Heat | Oxidation (burning microbes) | 160-170°C | Glassware, oils, powders, moisture-sensitive metals | Long cycle times, high temperatures |

| Chemical (EtO) | DNA disruption with gas | 30-60°C | Plastics, electronics, complex devices | Toxic residuals require aeration |

| Chemical (VHP) | Free radical destruction | 30-60°C | Surface sterilization of moisture/heat-sensitive items | Limited penetration capability |

| Radiation (Gamma) | DNA disruption with high-energy photons | Ambient (cold process) | Pre-packaged disposables (syringes, kits) | Requires significant safety shielding |

| Radiation (E-beam) | DNA disruption with electron beam | Ambient (cold process) | Uniform, low-density packaged products | Lower penetration than gamma |

Unsure which sterilization method is right for your lab materials?

Choosing the correct sterilization process is critical for protecting your sensitive equipment and ensuring effective results. KINTEK specializes in lab equipment and consumables, serving laboratory needs with expert guidance.

We can help you select the ideal sterilization solution—whether you work with heat-sensitive plastics, electronic components, powders, or complex medical devices. Our team provides the right equipment and support to ensure your materials are sterilized effectively without compromise.

Contact us today via the form below to discuss your specific sterilization challenges and discover the best solution for your laboratory.

Get Expert Sterilization Advice

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- What types of items and materials can be processed in a laboratory autoclave? Essential Guide for Lab Safety

- How is an autoclave utilized in antimicrobial experiments? Ensure Precise Nanoparticle Research Integrity

- What is the primary function of a laboratory Autoclave in seaweed hydrolysates? Sterilize and Optimize Fermentation

- What critical environmental conditions does a laboratory autoclave provide for evaluating wear resistance? - KINTEK

- How does a laboratory autoclave ensure the success of long-cycle continuous fermentation processes? Secure Pure Strains