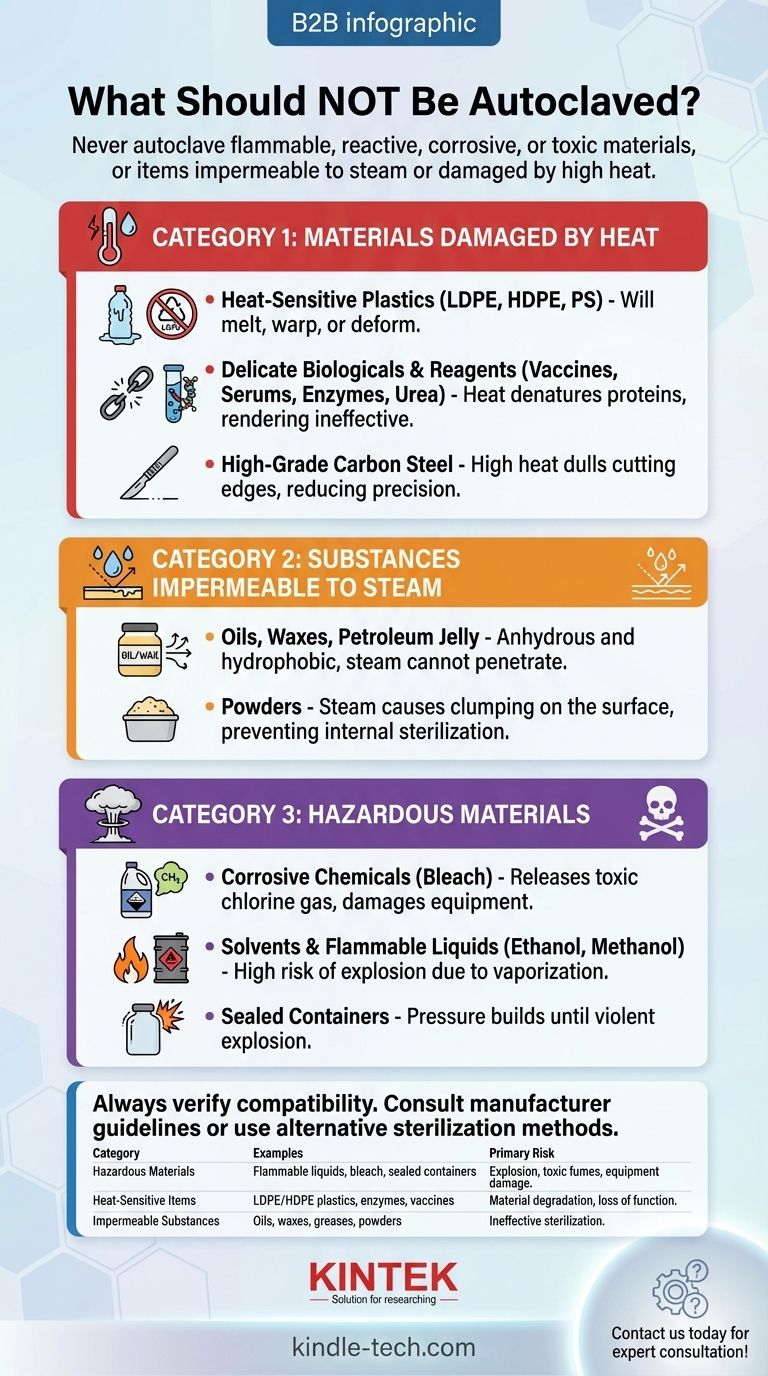

In short, you should never autoclave flammable, reactive, corrosive, or toxic materials, as well as any items that are impermeable to steam or can be damaged by high heat. This includes common laboratory materials like certain plastics, oils, powders, high-protein solutions, and sharp carbon steel instruments.

The core principle of autoclaving is sterilization using high-temperature, pressurized steam. Therefore, any material that is damaged by heat, cannot be penetrated by steam, or creates a safety hazard under these conditions is fundamentally unsuitable for this process.

The Principle: Why Autoclaves Work (and Fail)

An autoclave is not simply an oven. It uses a combination of intense heat (typically 121°C or higher) and high-pressure steam to denature proteins and kill microorganisms.

For this process to be effective, steam must make direct contact with every surface of the item being sterilized. This single concept explains why most materials fail.

Category 1: Materials Damaged by Heat

High temperatures will physically or chemically alter many common materials, rendering them useless or even hazardous.

Heat-Sensitive Plastics

Many plastics will melt, warp, or deform in an autoclave. You must verify the material before proceeding.

- Do Not Autoclave: Low-density polyethylene (LDPE), high-density polyethylene (HDPE), and polystyrene (PS) will melt.

- Safe to Autoclave: Polypropylene (PP) and polycarbonate (PC) are generally designed to withstand autoclave temperatures. Always check for the "autoclavable" symbol or manufacturer's specifications.

Delicate Biologicals and Reagents

The very process that kills microbes—denaturing proteins—will destroy sensitive biological samples and chemicals.

This includes vaccines, serums, enzymes, and certain protein solutions like urea. The heat will irreversibly break down the active molecules, making them ineffective.

High-Grade Carbon Steel

While stainless steel instruments are routinely autoclaved, sharp tools made of high-grade carbon steel, such as certain scalpel blades or scissors, should be sterilized by other means.

The high heat can dull the fine cutting edge, reducing the instrument's precision and lifespan.

Category 2: Substances Impermeable to Steam

If steam cannot touch a surface, it cannot be sterilized. This rule eliminates a wide range of water-insoluble substances.

Oils, Waxes, and Petroleum Jelly

These materials are anhydrous (contain no water) and hydrophobic (repel water). The steam will simply roll off the surface, leaving the bulk of the material completely unsterilized.

Powders

Similarly, powders are anhydrous. Steam tends to cause clumping on the outer surface, which prevents it from penetrating and sterilizing the powder within. These require dry heat sterilization instead.

Category 3: Items That Create a Hazard

Attempting to autoclave certain materials can damage the autoclave, release toxic fumes, or cause a catastrophic explosion. This is the most critical category to understand.

Corrosive Chemicals (Bleach)

Never autoclave sodium hypochlorite (bleach). When heated, it releases highly toxic chlorine gas. Furthermore, these corrosive vapors will cause severe and permanent damage to the stainless steel chamber of the autoclave.

Solvents and Flammable Liquids

This is extremely dangerous. Autoclaving liquids like ethanol, methanol, or other solvents creates a high risk of explosion. The high temperature will cause them to vaporize inside a pressurized chamber with no means of escape.

Sealed Containers

Placing a fully sealed, airtight container in an autoclave is like creating a bomb. As the temperature rises, the pressure inside the container will build until it explodes violently, potentially destroying the autoclave and causing serious injury.

All containers, even those with loose lids, must be properly vented to allow pressure to equalize.

Making the Right Choice for Your Goal

Always verify a material's compatibility before placing it inside an autoclave. When in doubt, consult the manufacturer's guidelines or choose an alternative sterilization method.

- If your primary focus is safety: Immediately prohibit all flammables, corrosives (especially bleach), and tightly sealed containers from being placed in the autoclave area.

- If your primary focus is preserving your materials: Be vigilant about heat-sensitive plastics, protein-based reagents, and sharp carbon steel instruments.

- If your primary focus is effective sterilization: Ensure complete steam penetration by never autoclaving oils, waxes, powders, or improperly packed dense fabrics.

Ultimately, understanding what not to autoclave is just as critical as knowing how to operate one correctly.

Summary Table:

| Category | Examples of Materials to Avoid | Primary Risk |

|---|---|---|

| Hazardous Materials | Flammable liquids (ethanol), corrosive chemicals (bleach), sealed containers | Explosion, toxic fumes, equipment damage |

| Heat-Sensitive Items | LDPE/HDPE plastics, enzymes, vaccines, carbon steel blades | Material degradation, loss of function |

| Impermeable Substances | Oils, waxes, greases, powders | Ineffective sterilization |

Ensure your lab's safety and protect your valuable equipment. Unsure about the best sterilization method for your specific materials? KINTEK specializes in lab equipment and consumables, serving all your laboratory needs. Our experts can help you choose the right solutions to maintain sterility without compromising safety or material integrity. Contact us today for a consultation!

Visual Guide

Related Products

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

People Also Ask

- What is the minimum temperature and time for autoclave? Achieve Guaranteed Sterilization Every Time

- What is the most effective method for sterilization of laboratory materials? Choose the Right Method for Your Lab

- What is autoclaving sterilization summary? A Complete Guide to Steam Sterilization

- What can you use an autoclave for? Essential Sterilization for Medical, Lab, and Industrial Needs

- What is the usual temperature of an autoclave? Master the 121°C Standard for Effective Sterilization

- What are the applications of autoclave? Essential Sterilization for Medical, Lab, and Industrial Needs

- What is the role of a high-pressure static autoclave in PWR coolant corrosion experiments? Essential Nuclear Testing

- How do high-pressure autoclaves facilitate the synthesis of mesoporous hydroxyapatite powders? Optimize Your Biomaterials