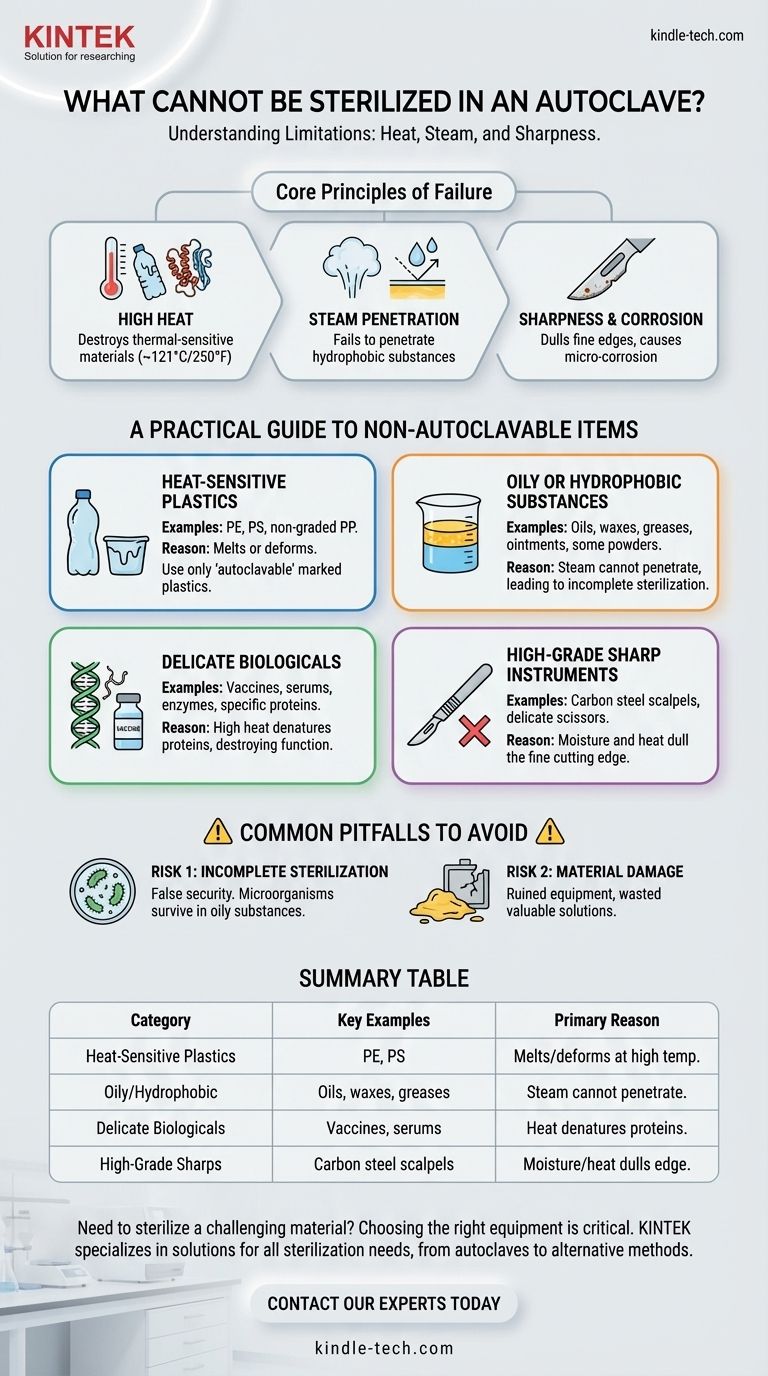

To be clear, several categories of materials cannot be safely or effectively sterilized in an autoclave. The primary unsuitable items include anything that is heat-sensitive, waterproof or water-repellent, or certain sharp instruments that can be damaged by the process. This includes many plastics, oily or waxy substances, delicate biologicals like vaccines, and high-grade carbon steel scalpels.

An autoclave relies on high-pressure saturated steam to sterilize. Therefore, any material that can be damaged by high temperatures (~121°C or 250°F) or that cannot be penetrated by steam will either be destroyed or remain non-sterile.

The Core Principles: Why Some Materials Fail

To understand what not to autoclave, we must first understand how it works. The process uses pressurized steam to transfer heat efficiently to every surface of an object, denaturing proteins and killing microorganisms. This mechanism is the root of its limitations.

The Problem with High Heat

An autoclave is fundamentally a high-heat environment. Any material lacking thermal stability will melt, warp, or degrade.

This is especially true for most standard plastics, which have a melting point lower than the autoclave's operating temperature. Likewise, sensitive biological solutions, such as vaccines, serums, or certain proteins, will be denatured and rendered useless by the intense heat.

The Necessity of Steam Penetration

Sterilization is only effective if the steam makes direct contact with every surface. Oily, waxy, or greasy substances are hydrophobic, meaning they repel water.

Because steam is simply the gaseous form of water, it cannot mix with or penetrate these materials. The heat transfer is inefficient, leaving pockets within the substance that never reach sterilization temperature.

The Issue of Sharpness and Corrosion

The combination of high heat and moisture can be corrosive and cause micro-dulling on the fine edges of certain instruments.

While many stainless steel surgical instruments are designed for autoclaving, high-grade carbon steel scalpels and scissors can lose their critical sharpness, compromising their performance.

A Practical Guide to Non-Autoclavable Items

Based on these principles, we can identify specific categories of materials that should never be placed in an autoclave.

Heat-Sensitive Plastics

Most common plastics, such as polyethylene (PE), polypropylene (PP) that isn't specifically graded for it, and polystyrene (PS), will melt or deform. Only use plastics that are explicitly marked as "autoclavable."

Oily or Hydrophobic Substances

This category includes oils, ointments, waxes, and some powders. Steam cannot penetrate these materials, making sterilization incomplete and unreliable.

Delicate Biologicals

Never autoclave sensitive biological materials where the protein structure is essential for function. This includes:

- Vaccines and serums

- Certain culture media components (e.g., urea)

- Enzymes and other specific proteins

High-Grade Sharp Instruments

To preserve the cutting edge of delicate or high-grade carbon steel instruments, alternative sterilization methods are often preferred. The moisture and heat can dull the blade edge.

Common Pitfalls to Avoid

Mistakes in sterilization protocol can lead to two critical failures: destroying valuable materials or, more dangerously, failing to achieve sterility.

Risk 1: Incomplete Sterilization

The most significant risk is assuming an item is sterile when it is not. Placing an oily substance in an autoclave gives a false sense of security. Microorganisms within the oil will survive the process, posing a major contamination risk.

Risk 2: Material Damage and Degradation

The most common mistake is autoclaving non-autoclavable plasticware, resulting in a melted mess that can damage the equipment and require extensive cleanup. Similarly, autoclaving sensitive solutions destroys their value and wastes resources.

Making the Right Choice for Your Goal

Selecting the correct sterilization method is critical for safety and success. Always consider the nature of the material you are processing.

- If your primary focus is sterilizing liquids, glassware, or surgical tools: The autoclave is an excellent choice, provided the materials are confirmed to be heat- and moisture-stable.

- If your primary focus is sterilizing heat-sensitive items (e.g., some plastics, delicate solutions): You must use an alternative method, such as filtration, chemical sterilization, or irradiation.

- If your primary focus is sterilizing hydrophobic substances (oils, powders): A steam autoclave is ineffective. Dry heat sterilization is the appropriate method for these materials.

Ultimately, effective sterilization depends entirely on matching the method to the material's physical and chemical properties.

Summary Table:

| Category of Non-Autoclavable Material | Key Examples | Primary Reason |

|---|---|---|

| Heat-Sensitive Plastics | Polyethylene (PE), Polystyrene (PS) | Melts or deforms at high temperatures (~121°C/250°F) |

| Oily/Hydrophobic Substances | Oils, waxes, greases, ointments | Steam cannot penetrate, leading to incomplete sterilization |

| Delicate Biologicals | Vaccines, serums, specific enzymes | High heat denatures proteins, destroying functionality |

| High-Grade Sharp Instruments | Carbon steel scalpels | Moisture and heat can dull the fine cutting edge |

Need to sterilize a challenging material? Choosing the right equipment is critical for lab safety and efficiency. KINTEK specializes in lab equipment and consumables, offering solutions for all your sterilization needs—from autoclaves for heat-stable items to guidance on alternative methods for sensitive materials. Contact our experts today to ensure your protocols are effective and your valuable materials are protected.

Visual Guide

Related Products

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

People Also Ask

- How does the autoclave kill microorganisms? The Power of Pressurized Steam for Sterility

- What are the sizes of autoclaves? A Guide to Choosing the Right Capacity for Your Lab

- What is the protocol for autoclave machine? A Step-by-Step Guide to Safe Sterilization

- What are autoclaves used in the chemical industry? High-Pressure Reactors for Synthesis & Curing

- What is the difference between types of autoclave? Choose the Right Sterilization Method for Your Lab

- What is the equivalent of an autoclave? Find the Right Sterilization Method for Your Needs

- What is the research value of using a high-pressure autoclave for curing geopolymer materials? Unlocking Durability

- What is the purpose of treating polyester fabric in an autoclave? Ensure Reliable Results in Lab Experiments