Vacuum distillation is a versatile and essential process used across various industries to separate and purify liquids with high boiling points or those that are heat-sensitive. By reducing the surrounding pressure, vacuum distillation allows these compounds to boil at lower temperatures, preventing decomposition and enabling the production of high-purity distillates. This method is widely applied in petroleum refining, chemical and pharmaceutical industries, desalination, and even in niche applications like craft spirit production. Its ability to handle heat-sensitive materials and achieve high levels of purity makes it indispensable in modern industrial processes.

Key Points Explained:

-

Petroleum Refining:

- Vacuum distillation is a critical step in refining crude oil. It separates heavy hydrocarbon fractions that cannot be distilled at atmospheric pressure due to their high boiling points.

- By lowering the pressure, these heavy fractions (such as lubricating oils, waxes, and asphalt) are distilled without thermal degradation, ensuring efficient processing and high-quality end products.

-

Chemical and Pharmaceutical Industries:

- These industries rely heavily on vacuum distillation for the purification of heat-sensitive compounds and high-boiling-point liquids.

- It is used to produce high-purity solvents, reagents, and active pharmaceutical ingredients (APIs) that would decompose at their normal boiling points.

- The process ensures the integrity and stability of delicate chemical compounds, making it indispensable for research and manufacturing.

-

Desalination:

- Vacuum distillation is employed in large-scale desalination plants to remove salt from seawater and produce fresh water.

- By reducing the pressure, the boiling point of water is lowered, making the process energy-efficient and cost-effective for producing potable water in arid regions.

-

Food and Beverage Industry:

- Vacuum distillation is used in the production of high-quality edible oils, flavors, and fragrances.

- It helps preserve the delicate aromas and flavors of heat-sensitive compounds, ensuring the final product retains its desired characteristics.

- For example, craft distilleries like Empirical Spirits use vacuum distillation to create unique spirits with distinct flavors by processing ingredients like Koji, Pilsner Malt, and Belgian Saison Yeast at lower temperatures.

-

Specialized Applications:

- Vacuum distillation is utilized in niche applications, such as the production of essential oils, where maintaining the integrity of volatile compounds is crucial.

- It is also used in the recycling industry to recover valuable solvents and chemicals from waste streams, contributing to sustainability efforts.

-

Advantages of Vacuum Distillation:

- Lower Operating Temperatures: Prevents thermal decomposition of sensitive compounds.

- Energy Efficiency: Reduces energy consumption compared to traditional distillation methods.

- High Purity: Ensures the production of high-purity distillates, which is critical in industries like pharmaceuticals and chemicals.

- Versatility: Can be combined with other distillation techniques, such as steam or fractional distillation, for enhanced separation efficiency.

-

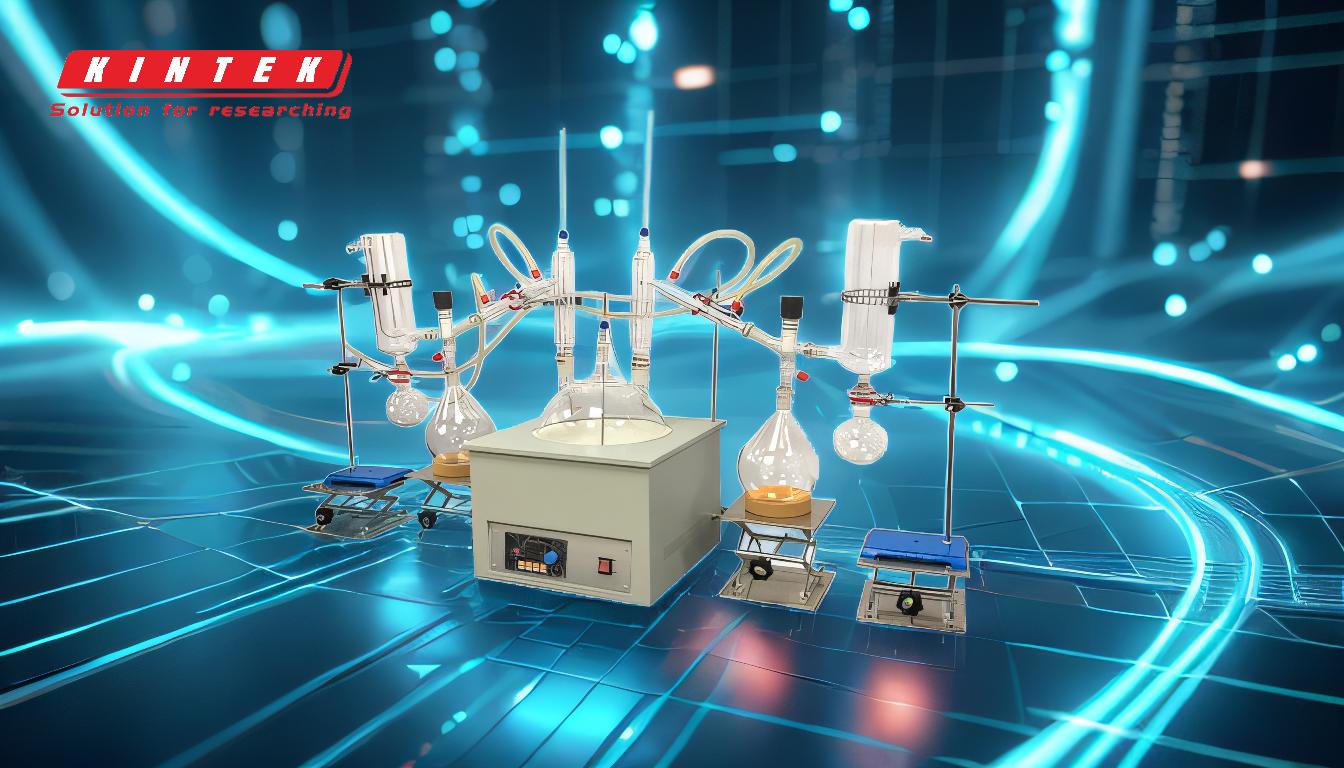

Equipment and Process Considerations:

- Vacuum distillation requires specialized equipment, including vacuum pumps, condensers, and distillation columns, designed to operate under reduced pressure.

- The process must be carefully controlled to maintain consistent pressure and temperature conditions, ensuring optimal separation and product quality.

In summary, vacuum distillation is a vital technique across multiple industries, enabling the efficient and safe separation of high-boiling-point and heat-sensitive compounds. Its applications range from large-scale industrial processes like petroleum refining and desalination to niche uses in craft spirit production and essential oil extraction. The method's ability to operate at lower temperatures and produce high-purity distillates makes it a cornerstone of modern industrial and scientific practices.

Summary Table:

| Industry | Application |

|---|---|

| Petroleum Refining | Separates heavy hydrocarbon fractions without thermal degradation. |

| Chemical & Pharmaceuticals | Produces high-purity solvents, reagents, and APIs for sensitive compounds. |

| Desalination | Removes salt from seawater efficiently, producing potable water. |

| Food & Beverage | Preserves delicate flavors and aromas in edible oils, spirits, and fragrances. |

| Specialized Applications | Extracts essential oils and recovers solvents from waste streams sustainably. |

| Advantages | Lower operating temperatures, energy efficiency, high purity, and versatility. |

Learn how vacuum distillation can optimize your industrial processes—contact our experts today!