In a laboratory, the autoclave should be located as close as possible to the point of use to streamline workflow, but isolated from high-traffic areas to ensure safety. This often means placing it in a dedicated, well-ventilated utility room or alcove directly adjacent to the main laboratory space where materials are handled. The primary goal is to minimize the travel distance for contaminated items.

The decision of where to place an autoclave is not merely about convenience; it is a critical intersection of operational efficiency and biosafety. The ideal location balances immediate access for sterilizing materials with necessary isolation to protect personnel from heat, steam, and potential biohazards.

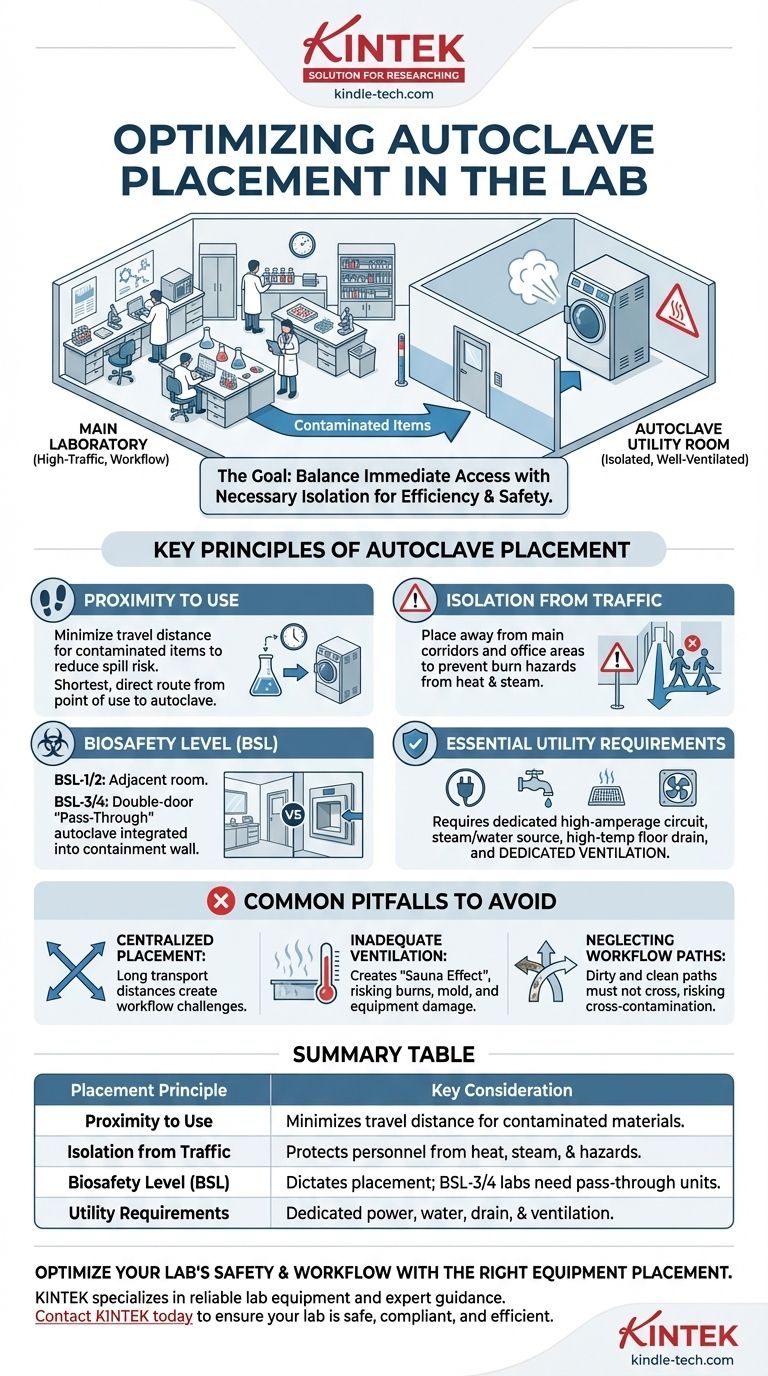

Key Principles of Autoclave Placement

Choosing the right location requires considering workflow, safety, and utility infrastructure. Each factor plays a crucial role in creating a safe and efficient laboratory environment.

Proximity to the Point of Use

The path materials take to and from the autoclave is a primary concern. A well-placed autoclave shortens this path, reducing risks and saving time.

Contaminated materials should travel the shortest, most direct route possible to the autoclave to minimize the chance of spills or aerosol generation in clean areas. Likewise, retrieving sterile items should be simple to maintain their sterility.

Isolation from Main Traffic Corridors

Autoclaves generate significant heat and release hot steam, creating a potential burn hazard. They are also pressurized vessels, which carry inherent operational risks.

Placing the unit away from main walkways, office areas, and sensitive equipment prevents accidental contact and injury. A dedicated alcove or separate room is the standard and safest approach.

Management of Biohazardous Materials

The location is directly dictated by the biosafety level (BSL) of the laboratory. The goal is to contain contaminated waste effectively.

For BSL-1 and BSL-2 labs, placing the autoclave in an adjacent room is common. For higher-containment BSL-3 or BSL-4 labs, a double-door "pass-through" autoclave is often required. This type of unit is built into the wall of the containment suite, allowing materials to be sterilized as they exit the controlled space, ensuring no contaminants can escape.

Essential Utility Requirements

An autoclave has significant infrastructure needs that constrain its location. It cannot be placed just anywhere.

It requires a dedicated, high-amperage electrical circuit, a source for steam or purified water, and a floor drain capable of handling high-temperature discharge. Most importantly, the space must have dedicated ventilation to exhaust the immense heat and moisture the machine generates during its cycle.

Understanding the Trade-offs and Common Mistakes

Failing to balance competing priorities can lead to unsafe conditions or an inefficient lab. Understanding these common pitfalls is essential for proper planning.

Centralized vs. Decentralized Placement

A large, centralized autoclave facility serving an entire floor or building can be cost-effective to build and maintain. However, it often creates significant workflow challenges, forcing researchers to transport materials over long distances.

Conversely, smaller, decentralized autoclaves located within or next to individual labs offer superior workflow. The trade-off is higher initial cost and a greater maintenance burden for the institution.

Inadequate Ventilation

A frequent and dangerous mistake is installing an autoclave in a small closet or room without proper HVAC considerations. This creates a "sauna effect," raising the ambient temperature and humidity to unsafe levels.

This not only poses a burn risk to operators but can also damage the autoclave's electronics over time and promote mold growth in the surrounding area.

Neglecting Workflow Paths

Placing the autoclave based solely on where utilities are available, without analyzing how staff will move, is a critical error. This can lead to inefficient routes where "dirty" contaminated paths cross "clean" sterile paths.

This cross-contamination risk undermines the very purpose of the autoclave and compromises the integrity of the lab's work. A clear, one-way flow from dirty to clean is the ideal.

Making the Right Choice for Your Lab

The final decision depends on the specific work being performed and the lab's biosafety designation.

- If your primary focus is a BSL-1 or BSL-2 research/teaching lab: Place the autoclave in an adjacent, well-ventilated utility room with a clear path for moving materials.

- If your primary focus is a high-containment BSL-3 or BSL-4 facility: The autoclave must be a pass-through model integrated directly into the physical barrier of the containment zone.

- If your primary focus is a small, low-throughput clinic or lab: A self-contained benchtop model may suffice, but it must be in a designated area away from the main workflow with adequate ventilation and heat clearance.

Ultimately, thoughtful autoclave placement is a foundational element of a safe, compliant, and efficient laboratory.

Summary Table:

| Placement Principle | Key Consideration |

|---|---|

| Proximity to Use | Minimizes travel distance for contaminated materials to reduce spill risk. |

| Isolation from Traffic | Protects personnel from heat, steam, and operational hazards. |

| Biosafety Level (BSL) | Dictates placement; BSL-3/4 labs require pass-through autoclaves. |

| Utility Requirements | Needs dedicated power, water/steam source, drain, and ventilation. |

Optimize your lab's safety and workflow with the right equipment placement. The correct location for an autoclave is critical for protecting your team and ensuring efficient operations. KINTEK specializes in providing reliable lab equipment and expert guidance for laboratories of all sizes. Let our specialists help you select and position the ideal autoclave for your specific needs. Contact KINTEK today to ensure your lab is safe, compliant, and efficient.

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

People Also Ask

- Why is a laboratory autoclave necessary for carbohydrate composition analysis? Unlock Accurate Sugar Yields

- What type of instruments Cannot be autoclaved? Protect Your Equipment from Heat and Moisture Damage

- How long does a typical autoclave run? Understand the Full Cycle for Safe Sterilization

- How does a high-pressure autoclave assist in acid etching TiO2 nanobelts? Enhance Surface Area and Reactivity

- What is the research value of using a high-pressure autoclave for curing geopolymer materials? Unlocking Durability

- What is an autoclave used for in a lab? Achieve Total Sterilization for Lab Safety and Integrity

- What damage is caused by autoclave? Protect Your Lab Equipment from Heat and Steam Damage

- What is the proper pressure and temperature for sterilizing instruments? Achieve True Sterility with the Right Parameters