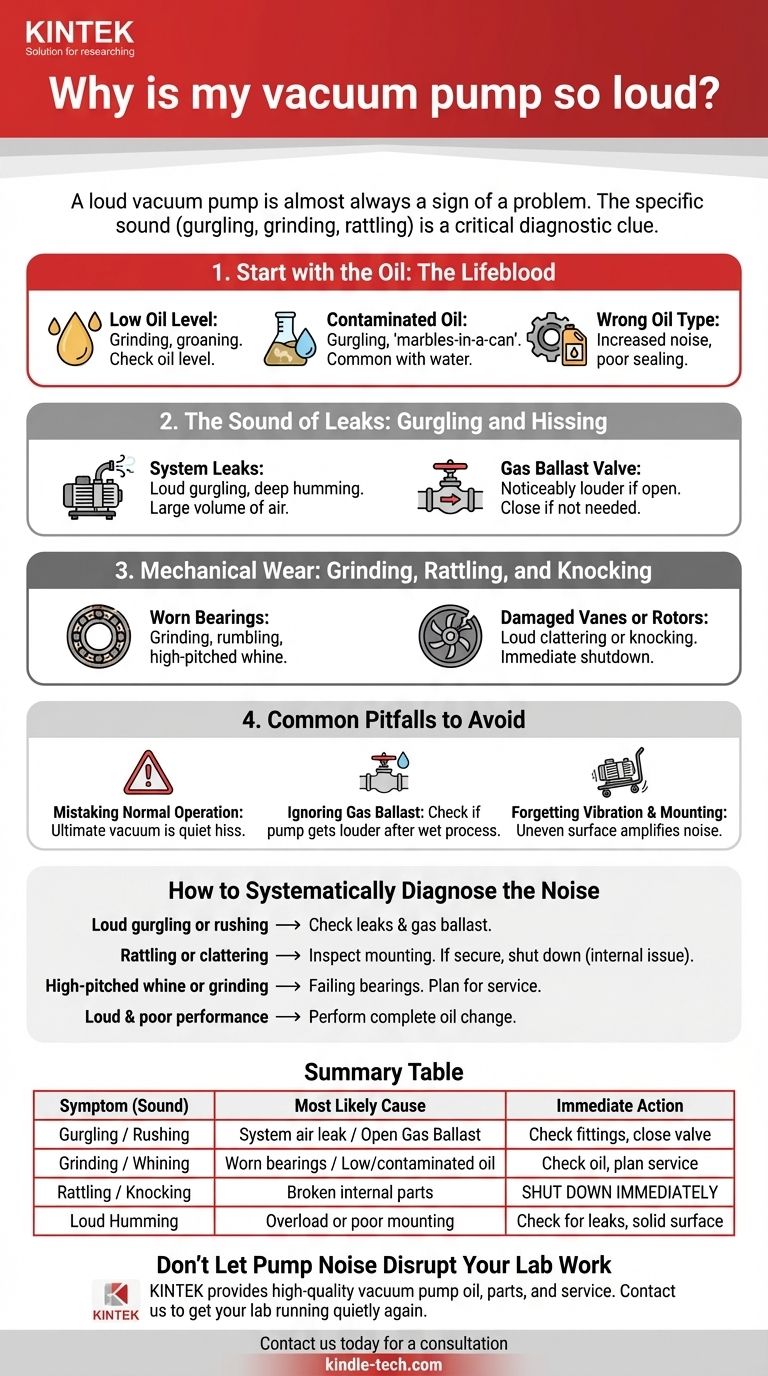

A loud vacuum pump is almost always a sign of a problem with one of three things: the air it's trying to move, the oil it uses to function, or its internal mechanical components. The specific sound it's making—whether it's gurgling, grinding, or rattling—is a critical clue to identifying the root cause, which can range from a simple air leak to serious internal wear.

The noise from your vacuum pump isn't just an annoyance; it's a critical diagnostic signal. By methodically isolating the type of noise and where it's coming from, you can accurately diagnose the underlying issue—from routine maintenance like an oil change to serious mechanical failure.

A Diagnostic Framework: From Simple Fixes to Serious Issues

A systematic approach is the most effective way to troubleshoot pump noise. Always start with the simplest and most common culprits before assuming a major mechanical failure.

Start with the Oil: The Lifeblood of Your Pump

The oil in a vacuum pump serves three functions: it lubricates moving parts, creates seals for compression, and helps dissipate heat. Problems with the oil are the leading cause of pump noise and failure.

- Low Oil Level: Insufficient oil means metal parts are not properly lubricated, leading to friction, overheating, and a grinding or groaning sound. This is a simple visual check.

- Contaminated Oil: Moisture, solvents, or particulates in the oil reduce its ability to lubricate and seal. Water contamination is common and will often cause a loud, gurgling or "marbles-in-a-can" sound as the pump tries to compress the incompressible liquid.

- Wrong Oil Type: Using oil with the wrong viscosity (e.g., motor oil instead of specified vacuum pump oil) will cause poor sealing and lubrication, leading to increased noise and eventual damage.

The Sound of Leaks: Gurgling and Hissing

Vacuum pumps are designed to move gas, but the amount of gas they are moving directly impacts their sound.

- System Leaks: A significant leak in your vacuum hoses, fittings, or chamber allows a large volume of air to rush into the pump. This overload forces the pump to work much harder, resulting in a loud gurgling or deep humming sound.

- Gas Ballast Valve: Many pumps have a gas ballast valve, which is designed to intentionally let a small amount of air into the pump. This helps purge condensed moisture from the oil. An open gas ballast will make the pump noticeably louder by design. If you don't need it, ensure it's closed.

Mechanical Wear: Grinding, Rattling, and Knocking

These sounds are more severe and often point to a permanent internal problem that requires immediate attention.

- Worn Bearings: Bearings allow the pump's internal motor and rotors to spin smoothly. As they wear out, they will produce a distinct grinding, rumbling, or high-pitched whining sound that often gets worse as the pump warms up.

- Damaged Vanes or Rotors: In a rotary vane pump, sliding vanes create the vacuum seal. If a vane chips, breaks, or gets stuck, it will cause a loud clattering or knocking sound as it strikes the pump housing. This requires an immediate shutdown to prevent catastrophic failure.

Common Pitfalls and What to Avoid

Misdiagnosing the noise can lead to unnecessary downtime or costly repairs. Understanding these common mistakes is key to getting it right.

Mistaking Normal Operation for a Problem

Not all noise is a sign of trouble. A pump pulling down a large volume will sound different from one holding a deep vacuum. A pump at its ultimate vacuum often has a quiet, high-pitched hiss, which is perfectly normal.

Ignoring the Gas Ballast Feature

Many users are unaware of the gas ballast valve. If you've been running a process with high water vapor and the pump suddenly gets louder, check this valve first. Someone may have opened it for purging and forgotten to close it.

Forgetting About Vibration and Mounting

The pump itself may be fine, but its environment can be the source of the noise. A pump placed on an uneven or resonant surface (like a thin metal cart) will amplify its normal operating vibrations into a loud hum or rattle. Always ensure the pump is on a level, solid foundation with its rubber feet intact.

How to Systematically Diagnose the Noise

Use the sound itself as your primary guide to find the solution.

- If the sound is a loud gurgling or rushing: Your first step is to check for leaks in your system and ensure the gas ballast valve is closed (unless you are actively purging contaminants).

- If the sound is a rattling or clattering: Immediately inspect the pump's mounting. If it is secure, the problem is likely internal (e.g., broken vanes) and requires professional service. Shut the pump down.

- If the sound is a high-pitched whine or grinding: This strongly suggests failing bearings. You should plan for a pump rebuild or replacement to avoid a sudden seizure during a critical process.

- If the pump runs loudly and performance is poor: Your first and most important step should always be to perform a complete oil change using the manufacturer-specified oil.

By treating noise as data, you can move from reacting to a problem to proactively managing the health of your equipment.

Summary Table:

| Symptom (Sound) | Most Likely Cause | Immediate Action |

|---|---|---|

| Gurgling / Rushing | System air leak or open Gas Ballast valve | Check fittings & hoses; close Gas Ballast |

| Grinding / Whining | Worn bearings or low/contaminated oil | Check oil level/quality; plan for service |

| Rattling / Knocking | Broken internal parts (e.g., vanes) | Shut down immediately; contact a technician |

| Loud Humming | Pump overloaded or poor mounting | Check for leaks; ensure pump is on a solid, level surface |

Don't Let Pump Noise Disrupt Your Lab Work

A noisy vacuum pump can lead to unexpected downtime and compromise your experiments. KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you diagnose the issue and provide the right high-quality vacuum pump oil, replacement parts, or service to get your lab running quietly and efficiently again.

Contact us today for a consultation and keep your critical processes on track. #ContactForm

Visual Guide

Related Products

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- How does the sample size affect the needed accuracy of the measurement? Optimize Your Data Quality

- How does brazing work? Create Strong, Permanent Metal Joints with Metallurgical Bonding

- What are the most common elemental analysis techniques? Choose the Right Tool for Your Material Analysis

- Why is a 24-hour slow furnace cooling process necessary after annealing? Ensure Ceramic Integrity and Data Stability

- What is the significance of a high-shear homogenizer in membrane preparation? Ensure Superior Casting Performance

- How does rapid quenching equipment stabilize actinide elements? Mastering Advanced Nuclear Waste Treatment

- What is the bias of sputtering RF? How a Negative DC Self-Bias Enables Insulator Sputtering

- What are the benefits of the sintering process? Unlock Precision, Material Purity, and Cost-Effective Mass Production