Introduction to Rotary Evaporation

Rotary evaporation is a common technique used in laboratories to purify and separate solvents from chemical compounds. It involves the use of a rotary evaporator, also known as a rotovap, which applies a vacuum and heat to a mixture of solvents to evaporate the volatile components. The rotary evaporator consists of a flask that rotates on a heating bath, a condenser to cool the vapors, and a vacuum pump to create a reduced pressure atmosphere. This process is ideal for removing solvents from a sample while preserving the integrity of the compounds. Rotary evaporation is widely used in the chemistry, pharmaceutical, and chemical engineering industries for research and development, quality control, and production purposes.

Table of Contents

Principle of Rotary Evaporation

Rotary evaporation is a technique used in laboratories to distill solvents and other liquids. The principle of rotary evaporation is based on the concept of reducing the pressure inside a closed vessel to lower the boiling point of the liquid. This is achieved by rotating the flask containing the liquid in a heated water bath, while a vacuum pump removes the evaporated solvent. Let's go through the principle step by step:

Step 1: Reduce Pressure

The first step in rotary evaporation involves reducing the pressure inside the flask. This is done by attaching a vacuum pump to the flask and turning it on. The vacuum pump removes the air molecules from the flask, creating a partial vacuum inside the container.

Step 2: Heat the Flask

The second step involves heating the flask. A water bath is usually used to heat the flask. The temperature of the water bath should be set to just below the boiling point of the liquid. The flask is then placed in the water bath, and the temperature of the bath is gradually increased until the liquid starts to evaporate.

Step 3: Rotate the Flask

The third step involves rotating the flask. The flask is rotated at a constant speed, which increases the surface area of the liquid and helps to speed up the evaporation process. The rotation speed can be adjusted depending on the type of liquid being distilled.

Step 4: Collect the Solvent

As the solvent evaporates, it forms a vapor that is removed from the flask by the vacuum pump. The vapor is then condensed back into a liquid by a condenser and collected in a receiving flask. The receiving flask is usually located outside the water bath to prevent the solvent from re-evaporating.

Step 5: Adjust Temperature and Vacuum Settings

The temperature and vacuum settings should be carefully controlled to obtain precise distillation results. The temperature of the water bath should be set just below the boiling point of the liquid, and the vacuum should be adjusted to achieve the desired rate of evaporation. It is also important to use the appropriate glassware and accessories for the specific application, such as a cold trap to prevent loss of the solvent and a chiller to maintain a constant temperature.

In conclusion, rotary evaporation is a powerful technique that can be used to obtain highly concentrated and pure samples. By following the above steps and carefully controlling the temperature and vacuum settings, precise distillation results can be obtained.

Standard Features of a Rotovap

A rotovap, also known as a rotary evaporator, is an essential laboratory equipment used for the distillation of solvents, especially heat-sensitive solvents. To obtain precise distillation results, it is important to understand the standard features of a rotovap.

Flask and Evaporating Flask

A typical rotovap consists of a flask that is filled with the solvent to be distilled and a rotating evaporating flask that is heated by a water bath or hot oil to evaporate the solvent. The evaporated solvent is then condensed and collected in a separate flask.

Rotating Flask

The rotating flask is driven by a motor, and the speed of rotation can be adjusted to control the rate of evaporation. This feature enables the user to control the distillation process to get the desired results.

Vacuum Pump

The vacuum pump is another critical feature of a rotovap, which lowers the pressure inside the system to reduce the boiling point of the solvent and prevent it from boiling too aggressively. The vacuum also helps to remove the solvent vapor from the system more efficiently.

Heating Bath

The heating bath is another essential feature of a rotovap, which provides a constant source of heat for the evaporating flask. This feature ensures that the solvent in the flask evaporates at a constant temperature, leading to accurate and precise results.

Cooling Coil

The cooling coil is a feature that enables the user to control the temperature of the evaporated solvent, which is then condensed and collected in the receiving flask.

Vacuum Gauge

The vacuum gauge is a feature that enables the user to monitor the pressure inside the system. This feature helps to ensure that the distillation process is happening at the right pressure, leading to accurate and precise results.

Proper use of these standard features, along with careful monitoring of the temperature and pressure, can help to ensure precise and efficient distillation results. A rotovap is a valuable tool for any laboratory that needs to distill solvents with high precision and efficiency.

How to Properly Use a Rotovap

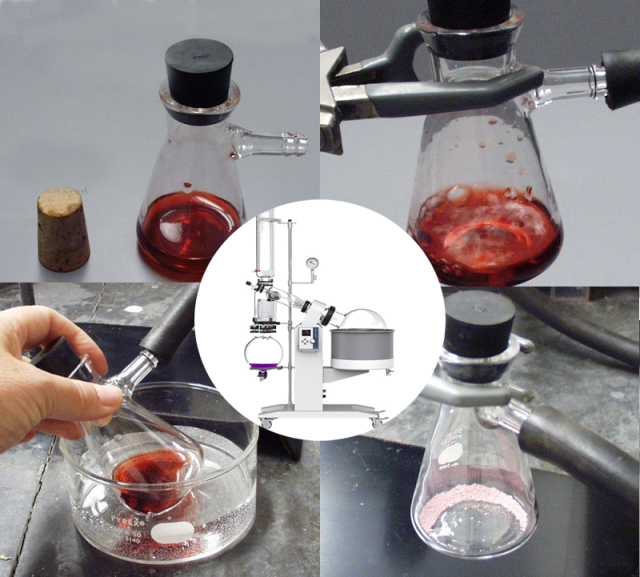

Step 1: Rotary Evaporator Setup

- Pour the solvent and desired compound in a round-bottom flask, filling it less than half full of the solution.

- Fill the rotovap cold traps with dry ice.

- Attach a glass “bump trap” to prevent any solution from entering the main part of the rotovap. Secure with a Keck clip.

- Attach the flask and bump trap to the adapter portion of the rotovap with another Keck clip.

- Lower the flask into the water bath to prevent disconnection.

Step 2: Rotary Evaporator Operation

- Start the rotation at the proper speed for the volume.

- Slowly increase the vacuum. The vacuum is at the proper strength when the solvent begins to bubble or condensation of the solvent can be seen on the cold finger or in the receiving flask.

- Turn on the heat for the water bath. Remember that the vacuum reduces the boiling point of the solvent, so a lower temperature is needed to evaporate the solvent using a rotovap than at STP.

- Adjust the vacuum setting as needed.

- Turn off the vacuum and return the flask to atmospheric pressure after all solvent has been removed.

- Stop the rotation.

- Raise the flask from the bath and remove it from the adapter.

Tips and Tricks

- Distilled water should be used in the heating bath to minimize the scale build-up in the bath, which coats the thermistor and heating coils. Regular tap water will promote the growth of algae colonies.

- Regular maintenance and cleaning of the rotovap is crucial in ensuring its optimal performance.

- When using a rotary evaporator, you need to pay attention to the rotation rate, make sure you rotate the flask moderately, preferably one-third of the maximum allowable value.

- The ground glass joint holding the flask does not need to be greased, but on rare occasions, it may get “frozen”. Some companies sell special joint clips that can free frozen joints simply by screwing them in one direction. If you are not lucky enough to have these and cannot release the joint, ask your teaching assistant for advice.

- The solvent collection flask should always be emptied prior to use to prevent accidentally mixing of incompatible chemicals.

- The flask with the solution is placed on the rotary evaporator. The use of a bump trap prevents the solution from accidentally splashing into the condenser and being contaminated.

- A metal or Keck clip is used to secure the flask and the bump trap.

- The aspirator vacuum is turned on. On most models, the vacuum on/off control is managed by turning a stopcock at the top of the condenser.

- The cooling bath on the receiver or use of a dry-ice condenser can be used to prevent solvents from evaporating from the receiving flask and being discharged down the drain.

- The bump trap has to be cleaned, and the receiving flask is emptied upon completion of the evaporation.

By following these steps and tips, you can properly use a rotovap and achieve precise distillation results. Remember to always prioritize safety and follow proper maintenance procedures to ensure optimal performance.

Tips and Tricks for Efficient Rotovap Operation

Proper Preparation of Sample

- Filter the sample to remove any impurities.

Secure Attachment and Correct Temperature

- Ensure that the flask is securely attached to the rotovap.

- Set the temperature correctly.

Monitor Vacuum Level and Adjust as Necessary

- Monitor the vacuum level and adjust it as necessary.

Use Bump Trap and Cold Trap

- Use a bump trap and cold trap to prevent contamination and loss of product.

Work Carefully and Slowly

- Work carefully and slowly to avoid any accidents or spills.

Thoroughly Clean Equipment After Use

- Clean the equipment thoroughly after use to prevent any contamination of future samples.

By following these tips and tricks, you can achieve efficient operation and precise distillation results from a rotovap. Proper preparation of the sample is the first step to achieve this. The sample should be filtered to remove any impurities. Once the sample is ready, ensure that the flask is securely attached to the rotovap and the temperature is set correctly. It is also important to monitor the vacuum level and adjust it as necessary. Using a bump trap and cold trap is recommended to prevent contamination and loss of product.

When using a rotovap, it is important to work carefully and slowly to avoid any accidents or spills. Cleaning the equipment thoroughly after use is also crucial to prevent any contamination of future samples. By following these tips and tricks, you can ensure efficient operation and precise distillation results from a rotovap.

Conclusion

In conclusion, rotary evaporation is a highly efficient and effective method for distilling a wide range of materials. By using a rotovap, you can achieve precise distillation results and extract pure substances from complex mixtures. When selecting a rotovap for your lab, consider your specific needs and requirements, such as the volume of material you will be distilling and the level of precision required. With proper use and care, a rotovap can be an invaluable tool in your laboratory. We hope that this guide has provided you with a useful introduction to rotary evaporation and has helped you understand the principles and features of this powerful technique.

CONTACT US FOR A FREE CONSULTATION

KINTEK LAB SOLUTION's products and services have been recognized by customers around the world. Our staff will be happy to assist with any inquiry you might have. Contact us for a free consultation and talk to a product specialist to find the most suitable solution for your application needs!