Table of Contents

- Introduction to XRF Spectrometer Modules

- Key Components of XRF Spectrometers

- Types of XRF Spectrometers: ED-XRF vs. WD-XRF

- Applications of XRF Spectrometers Across Industries

- Advanced Features and Customizations in XRF Spectrometers

- Practical Guide to Using XRF Spectrometers for Metal Surveillance

- Common Challenges and Solutions in XRF Analysis

- Future Trends and Innovations in XRF Spectrometer Technology

Introduction to XRF Spectrometer Modules

XRF spectrometer modules are integral to elemental analysis in various industries, evolving from laboratory-based to portable devices. This comprehensive guide explores the intricacies of XRF spectrometers, including their fundamental components and the principle of operation. It discusses the types of XRF spectrometers, their applications across industries, and the advanced features that enhance their versatility. The guide also provides practical guidance on using XRF spectrometers for metal surveillance and addresses common challenges in XRF analysis. Furthermore, it delves into future trends and innovations in XRF spectrometer technology, highlighting advancements in detector technology, software enhancements, and the integration of AI for data analysis.

Key Components of XRF Spectrometers

XRF spectrometers are sophisticated instruments used for non-destructive analysis of metal coatings and materials. Understanding the key components of an XRF spectrometer is crucial for optimizing its performance and ensuring accurate results. These components include the X-ray tube, detector, aperture, focusing system, and camera.

X-ray Tube: The X-ray tube is the core component of an XRF spectrometer, responsible for generating the X-rays that interact with the sample. These tubes produce high-energy X-rays that are directed towards the sample. The quality and intensity of the X-rays produced by the tube significantly influence the accuracy and sensitivity of the analysis. Modern X-ray tubes are designed to provide stable and intense X-ray beams, which are essential for obtaining reliable and precise measurements.

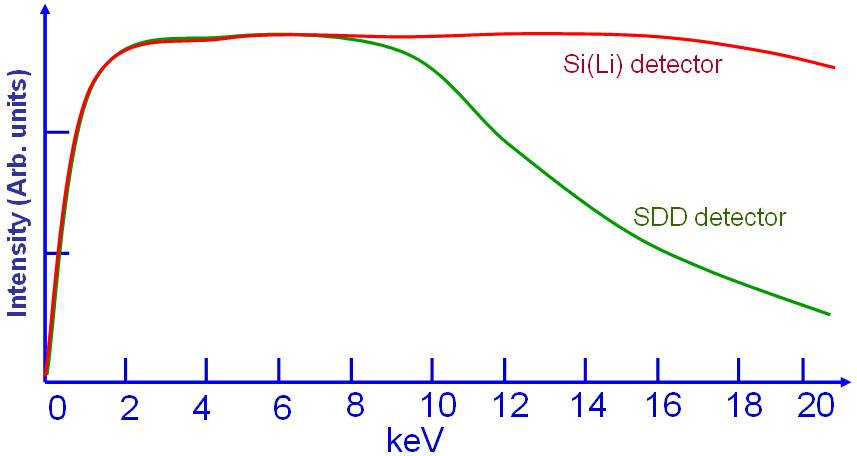

Detector: The detector in an XRF spectrometer is tasked with capturing the X-rays emitted by the sample. These detectors are capable of measuring both the energy and intensity of the X-rays, which are crucial for determining the elemental composition of the sample. There are different types of detectors used in XRF spectrometers, including proportional counters, scintillation detectors, and semiconductor detectors like Si(Li) and SDD (Silicon Drift Detector). Each type of detector has its own advantages in terms of speed, sensitivity, and resolution, and the choice of detector can impact the performance of the spectrometer.

Aperture: The aperture is a critical component that controls the size of the X-ray beam that illuminates the sample. The selection of the correct aperture is vital for precision and measurement efficiency. By adjusting the aperture, the spot size can be controlled, which directly affects the area of the sample being analyzed. This is particularly important in applications where the sample has a complex geometry or when analyzing small features.

Focusing System: The focusing system ensures that the X-rays are directed accurately onto the detector. It maintains a consistent geometric path between the X-ray tube, components, and detector for each measurement. Any deviation in this path can lead to inaccurate results. The focusing system is designed to optimize the X-ray beam's focus, enhancing the instrument's ability to detect and analyze the emitted X-rays with high precision.

Camera: The camera in an XRF spectrometer is used to precisely locate the measurement area on the sample. It aids in positioning the instrument correctly and can also provide image information for automated operation modules. In some advanced systems, the camera can magnify the image to allow for precise location of the area to be measured. This feature is particularly useful when dealing with small or intricate samples.

Each of these components plays a vital role in the overall functionality of an XRF spectrometer. By understanding and optimizing these components, users can ensure that their XRF analysis is both accurate and efficient, meeting the stringent specifications required for various industrial applications.

Types of XRF Spectrometers: ED-XRF vs. WD-XRF

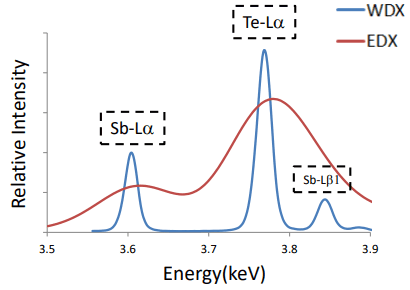

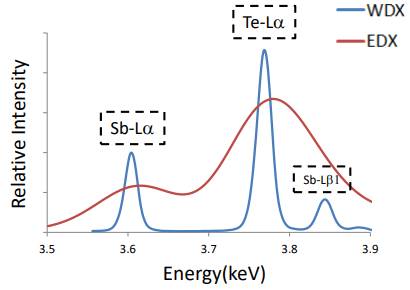

X-ray Fluorescence (XRF) spectrometry is a widely used analytical technique for elemental analysis across various industries. Two primary types of XRF spectrometers are Energy Dispersive XRF (ED-XRF) and Wavelength Dispersive XRF (WD-XRF), each with distinct advantages, resolution capabilities, and typical applications.

Energy Dispersive XRF (ED-XRF)

ED-XRF spectrometers are known for their simplicity and ease of use. They operate by simultaneously collecting X-ray signals from multiple elements in a sample. The resolution of ED-XRF typically ranges from 150 eV to 600 eV. This type of spectrometer is cost-effective and suitable for a wide range of applications, including environmental monitoring, quality control in manufacturing, and rapid screening in the field.

Advantages of ED-XRF:

- Simultaneous Analysis: ED-XRF can analyze multiple elements at once, which significantly speeds up the analytical process.

- Cost-Effectiveness: These spectrometers are generally less expensive than their WD-XRF counterparts, making them more accessible for small to medium-sized laboratories and businesses.

- Portability: Many ED-XRF devices are portable, allowing for on-site analysis without the need to transport samples to a lab.

Wavelength Dispersive XRF (WD-XRF)

WD-XRF spectrometers are more complex and expensive instruments, but they offer superior resolution, ranging from 5 eV to 20 eV. WD-XRF uses a goniometer to collect signals one at a time at different angles, providing more detailed and precise elemental analysis. This makes WD-XRF ideal for high-precision applications such as geological research, advanced materials science, and detailed forensic analysis.

Advantages of WD-XRF:

- High Resolution: The higher resolution of WD-XRF allows for the detection and quantification of elements at lower concentrations and with greater accuracy.

- Detailed Analysis: WD-XRF is capable of providing detailed spectral information, which is crucial for complex samples and advanced research.

- Robustness: These spectrometers are built to handle rigorous and continuous use, making them suitable for industrial and high-throughput laboratory settings.

Typical Applications

ED-XRF is commonly used in industries such as cement, metal ores, mineral ores, and environmental monitoring. Its portability and speed make it ideal for rapid screening and on-site analysis.

WD-XRF, on the other hand, is often found in advanced research facilities and high-precision industrial settings. It is particularly useful in applications requiring detailed elemental composition analysis, such as in the development of new materials or in forensic science.

Conclusion

Choosing between ED-XRF and WD-XRF depends largely on the specific needs of the application. ED-XRF offers a balance of cost-effectiveness and functionality, making it suitable for a broad range of general analytical tasks. WD-XRF, with its superior resolution and precision, is the preferred choice for applications requiring detailed and accurate elemental analysis. Both technologies play crucial roles in the field of XRF spectrometry, providing valuable tools for scientists and engineers across various disciplines.

Applications of XRF Spectrometers Across Industries

X-ray fluorescence (XRF) spectrometers are versatile tools with a wide range of applications across various industries. These devices are used for non-destructive testing and analysis of elemental composition, making them invaluable in sectors such as cement, metal ores, mineral ores, oil & gas, environmental, and geological sectors.

Cement Industry

In the cement industry, XRF spectrometers are crucial for quality control and process optimization. They help in determining the elemental composition of raw materials and finished products, ensuring that the cement meets the required standards for strength and durability.

Metal and Mineral Ores

Mining companies extensively use XRF spectrometers to analyze the elemental composition of ores. This helps in making critical decisions such as where to focus mining efforts, when to drill, and when to select samples. For instance, XRF is used to analyze minerals like phosphate and limestone, and even to detect indications of oil and gas in rock surfaces.

Oil & Gas Sector

In the oil and gas industry, XRF spectrometers are used for geological exploration and analysis. They help in identifying the elemental composition of rocks and sediments, which is crucial for determining the presence and quality of oil and gas reserves.

Environmental Sector

Environmental testing and soil remediation heavily rely on XRF spectrometers. These devices are used to detect harmful elements like lead, arsenic, or chromium in soil and other environmental samples. This is crucial for ensuring the safety of living and working environments.

Geological Applications

Geologists use XRF spectrometers for a variety of tasks, including mineral exploration and analysis. The devices help in quickly analyzing minerals and assessing the potential value of a site, which is essential for efficient resource allocation and management.

Other Industries

Beyond these core sectors, XRF spectrometers are also used in industries such as metallurgy, recycling, and jewelry. In metallurgy, XRF is used for quality control of raw materials and finished products. In the recycling industry, XRF machines are essential for quick and accurate sorting of metals and determining the elemental composition of scrap. Jewelers use XRF instruments to detect non-standard, under-karated, or counterfeit metals, which cannot be identified through traditional methods like acid testing.

Types of XRF Spectrometers

XRF spectrometers are primarily of two types: Energy Dispersive XRF (ED-XRF) and Wavelength Dispersive XRF (WD-XRF). ED-XRF spectrometers are simpler and easier to use, capable of simultaneously collecting signals from several elements. WD-XRF spectrometers, on the other hand, are more complex and expensive but offer higher resolution, collecting one signal at a time at different angles.

In conclusion, XRF spectrometers are indispensable tools in various industries due to their ability to provide quick, accurate, and non-destructive elemental analysis. Their applications range from quality control in manufacturing to environmental monitoring and geological exploration, highlighting their versatility and importance in modern science and industry.

Advanced Features and Customizations in XRF Spectrometers

XRF spectrometers are renowned for their versatility and precision in elemental analysis across various materials, including autocatalysts, alloys, and ores. The inclusion of advanced calibrations and customizations enhances their functionality, allowing for tailored analysis to meet specific user needs.

Improvements in Elemental Analysis

Modern XRF spectrometers have significantly improved in their ability to perform quick and non-destructive elemental analysis. Technological advancements have led to increased precision and accuracy, enabling users to obtain detailed information about the elemental composition of a sample. This is crucial for material identification and quality control. Portable XRF spectrometers, in particular, have seen improvements in performance, with faster analysis times that facilitate real-time decision-making. Enhanced sensitivity and detection limits now allow for the detection of trace elements at low concentrations, expanding the scope of materials that can be analyzed effectively.

Enhanced Connectivity and User-Friendly Features

In addition to analytical capabilities, modern XRF spectrometers are equipped with enhanced connectivity features. This includes the ability to export measurement reports and connect remotely via Wi-Fi, which aids in the quick dissemination of results and integration into broader data management systems. The user interface has also been designed to be more intuitive, with simple navigation that reduces the learning curve for operators, thereby increasing overall productivity.

Customizable Calibrations and Versatility

One of the standout features of XRF spectrometers is their ability to include multiple calibrations for different tasks. This means that a single device can be configured to handle a wide range of analytical tasks, from analyzing the composition of autocatalysts to assessing the quality of alloys and ores. The ability to customize calibrations ensures that the device can be optimized for specific applications, providing precise and reliable results.

Sample Analysis Capabilities

The versatility of XRF spectrometers extends to their ability to analyze various sample sizes and shapes. Whether the sample is solid, liquid, or powder, modern XRF spectrometers can accommodate different forms, ensuring comprehensive analysis. This is particularly important in industries where the physical characteristics of materials can vary significantly.

Catalyst Valuation and Measurement Averaging

For applications involving autocatalysts, XRF spectrometers offer specialized features such as Catalyst Valuation, which automatically calculates the value of an autocatalyst based on its weight, composition, and current trading prices of precious metals. Additionally, the ability to average measured values across heterogeneous samples provides a practical solution when precise sample preparation is not feasible, offering a reliable estimate of sample composition.

In conclusion, the advanced features and customizations available in XRF spectrometers significantly enhance their versatility and utility across a broad spectrum of materials and applications. These enhancements not only improve the accuracy and precision of elemental analysis but also make the devices more user-friendly and adaptable to specific analytical needs.

Practical Guide to Using XRF Spectrometers for Metal Surveillance

X-ray fluorescence (XRF) spectrometers are invaluable tools for metal surveillance, offering rapid, non-destructive analysis of metal compositions. To effectively use XRF spectrometers, it is crucial to understand the operational steps, safety measures, and optimization techniques.

Setting Clear Objectives

Before initiating any test, define clear goals and objectives. Whether the aim is to investigate stratigraphy, chemistry, or pre-screen samples, having a clear objective guides the testing process and ensures that the data collected is relevant and useful.

Training and Compliance

Invest in comprehensive training from qualified personnel. This training should cover XRF theory, the operation of handheld XRF analyzers, and radiation safety. Compliance with local regulations is also essential, as XRF regulations can vary significantly by region.

Initial Directional Survey

Begin with a directional survey using a handheld XRF analyzer. This initial step helps in understanding the default calibration of the analyzer and its impact on sample accuracy and precision. It also allows for the assessment of any necessary fine-tuning or calibration adjustments.

Optimization of Testing

Optimize testing time by focusing on elements of interest. This involves selecting the appropriate mode in the analyzer and understanding how factors such as heterogeneity, moisture, particle size, and sample containers can affect results.

Safety and Precision

XRF spectrometers are safe when used correctly. Always direct the analyzer at the sample and never at people or body parts. The fluorescence emitted is specific to the elemental composition of the sample, making XRF an excellent technique for qualitative and quantitative analysis.

Calibration and Quality Control

Regular calibration and quality control are essential. Establish a "fit for purpose" method and develop standard operating procedures (SOPs). Use matrix matching or site-specific certified reference materials (CRMs), and include blanks, duplicates, or replicates in your testing regimen to ensure accuracy and reliability.

Conclusion

XRF spectrometers are powerful tools for metal surveillance, offering rapid and accurate analysis. By setting clear objectives, adhering to safety protocols, and optimizing testing procedures, users can ensure the highest quality results. Remember, the effectiveness of an XRF analyzer depends not only on the instrument but also on the skill and knowledge of the operator.

Common Challenges and Solutions in XRF Analysis

XRF (X-ray Fluorescence) analysis is a powerful technique for determining the elemental composition of materials. However, several challenges can affect the accuracy and reliability of the results. Understanding these challenges and implementing appropriate solutions is crucial for enhancing analytical outcomes.

Factors Affecting XRF Analysis

Several factors can influence the results of XRF analysis:

-

Sample Characteristics: The depth at which elements are detected (typically 1-1000 µm below the surface) can vary based on the atomic weight of the elements. Lighter elements are harder to detect than heavier ones.

-

Instrument Calibration and Mode Selection: Proper calibration and selection of the correct mode in the analyzer are essential to ensure accurate measurements.

-

Sample Preparation: Issues such as heterogeneity, moisture content, particle size, and the type of sample container can significantly impact results. Establishing a "fit for purpose" method and standard operating procedures (SOPs) is critical.

-

Quality Control/Quality Assurance (QC/QA): Performing QC/QA checks, including matrix matching or using certified reference materials (CRMs), blanks, duplicates, or replicates, helps maintain the integrity of the analysis.

Common Challenges in XRF Analysis

The most common challenges in XRF analysis include:

-

Instrument Misuse: Incorrect use of the XRF spectrometer, such as improper calibration or mode selection, can lead to inaccurate results.

-

Part Geometry Impact: The geometry of the sample parts can affect the X-ray signal, leading to variations in the detected elements.

-

Sample Preparation Errors: Inadequate sample preparation, such as incorrect pelletizing techniques or poor homogenization, can introduce significant errors.

Solutions and Best Practices

To mitigate these challenges, the following best practices are recommended:

-

Proper Instrument Handling and Calibration: Ensure that the XRF spectrometer is used according to the manufacturer's guidelines and is regularly calibrated.

-

Optimized Testing Time: Adjust the testing time for elements of interest to enhance the signal-to-noise ratio and improve detection limits.

-

Accurate Sample Preparation: Use appropriate sample preparation techniques, including homogenization and correct pelletizing methods, to ensure uniform and representative samples.

-

Standard Operating Procedures (SOPs): Develop and adhere to SOPs that address all aspects of the XRF analysis process, from sample preparation to data interpretation.

-

Quality Control/Quality Assurance (QC/QA): Implement robust QC/QA protocols, including the use of certified reference materials and regular checks for instrument performance.

By addressing these challenges with the appropriate solutions, XRF analysis can provide accurate and reliable results, enhancing its utility in various scientific and industrial applications.

Future Trends and Innovations in XRF Spectrometer Technology

The field of X-ray fluorescence (XRF) spectrometry is experiencing significant advancements, driven by innovations in detector technology, software enhancements, and the integration of artificial intelligence (AI) for data analysis. These developments are not only improving the accuracy and efficiency of elemental analysis but also expanding the capabilities of XRF spectrometers in various scientific and industrial applications.

Advancements in Detector Technology

Recent improvements in detector technology have led to enhanced sensitivity and detection limits in XRF spectrometers. Modern detectors are capable of detecting trace elements at extremely low concentrations, which is crucial for applications in environmental monitoring, archaeology, and materials science. The development of more compact and efficient detectors has also facilitated the creation of portable XRF spectrometers that can perform high-precision analyses in the field, providing real-time data and enabling rapid decision-making processes.

Software Enhancements

Software plays a critical role in the operation and data analysis of XRF spectrometers. Current software enhancements focus on improving user interfaces to make XRF technology more accessible to non-experts. Intuitive software designs simplify the operation of these complex instruments, allowing a broader range of users to benefit from XRF analysis. Additionally, advanced data processing algorithms are being developed to handle the vast amounts of data generated by modern XRF spectrometers, ensuring that results are processed quickly and accurately.

Integration of AI for Data Analysis

The integration of AI into XRF technology is revolutionizing the way data is analyzed. AI algorithms can automatically adjust and calibrate analyzers, significantly reducing the time and resources required for traditional calibration methods. Machine learning (ML) enables analyzers to learn from a wide range of data sets and adapt to analyze different materials without manual intervention. This not only improves work efficiency but also minimizes the need for extensive preparation procedures.

AI also facilitates the automatic selection of the best calibration during the measurement process. Analyzers equipped with AI can analyze spectral data in real time and, by comparing it with a database, accurately determine the material type and select the necessary calibration. This capability not only enhances the accuracy and reliability of the analysis but also simplifies the process for operators, reducing the likelihood of errors and speeding up the analysis process.

Transformation through Cloud Technology

Cloud technology is another transformative trend in XRF spectrometry. The implementation of cloud services allows for the rapid processing of large amounts of data, the creation of dynamic dashboards to visualize results, and facilitates access to information for a wide range of users. Cloud platforms also enable data exchange between analyzers, promoting collaboration between research groups and organizations.

Conclusion

The future of XRF spectrometer technology is promising, with advancements in detector technology, software enhancements, and the integration of AI and cloud technology. These innovations are making XRF analysis faster, more accurate, and more efficient, providing improved solutions for materials science and many other scientific and industrial fields. As these technologies continue to evolve, the potential applications of XRF spectrometers are expected to expand, contributing significantly to the advancement of scientific research and industrial practices.

Related Products

- XRD Sample Holder X-ray Diffractometer Powder Slide

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

Related Articles

- What is xrf analysis and how to making pressed xrf pellets

- Techniques for Sample Preparation in X-Ray Fluorescence Analysis: Pressed and Loose Powder Methods

- How to Choose the Right XRF Pellet Press for Your Needs

- Effective Preparation of Samples for XRF Analysis via Pressed Pellets Method

- Guide for Xrf Pellet Press