Basic Principle of In Situ Infrared Spectroscopy

Definition and Function

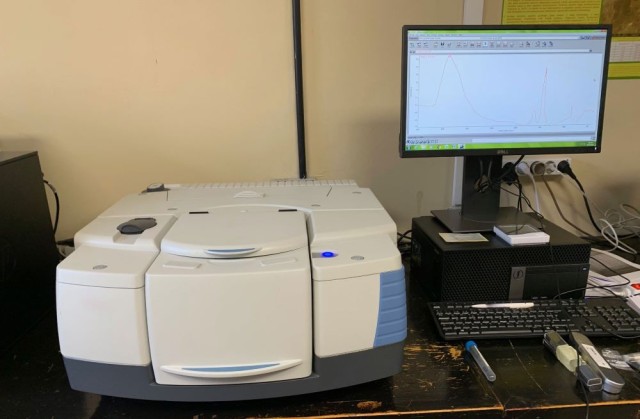

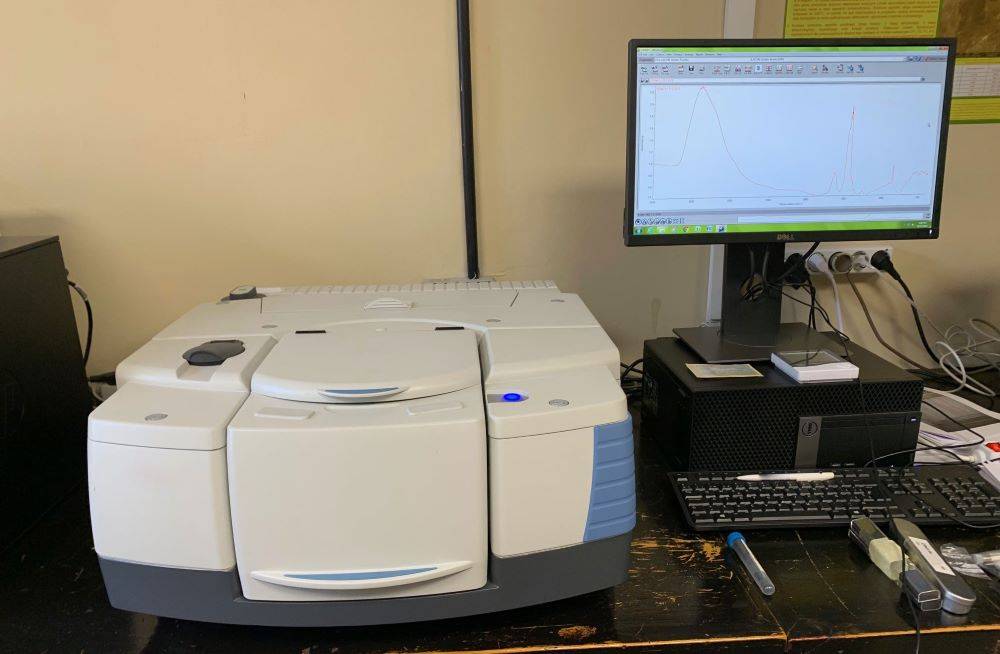

In Situ Infrared Spectroscopy (ISIS) is a powerful analytical tool designed to monitor dynamic changes within samples or reaction systems under varying conditions. This technique is invaluable for observing how materials respond to fluctuations in time, temperature, and environmental factors. By capturing these real-time changes, ISIS provides deep insights into the chemical and physical properties of materials, making it an essential method for researchers and scientists.

The primary function of ISIS lies in its ability to track the evolution of molecular structures and interactions. This capability is particularly useful in fields such as catalysis, where understanding the behavior of catalysts under different conditions can lead to significant advancements. For instance, ISIS can reveal how functional groups within a molecule change over time, or how structural transformations occur under elevated temperatures.

Moreover, ISIS is not limited to static observations; it can also be used to study reaction kinetics, where the rate and mechanism of a chemical reaction are of paramount importance. By continuously monitoring the reaction environment, ISIS can provide a comprehensive view of how reactants transform into products, offering critical data for optimizing reaction conditions and yields.

In summary, In Situ Infrared Spectroscopy serves as a dynamic lens through which researchers can explore the intricate world of material science and chemistry, enabling them to make informed decisions and drive innovation in their respective fields.

Technique Details

The technique of in situ infrared spectroscopy involves the direct analysis of reaction products within the infrared spectrum, specifically by recording either absorption or transmission spectra. This method allows for the identification of various molecular details, such as functional groups and structural changes, which are critical for understanding the chemical and physical properties of materials undergoing reactions.

By capturing these spectra, researchers can observe how molecular structures evolve over time, under different temperatures, and in response to environmental changes. This capability is particularly useful in fields such as catalyst characterization, reaction kinetics, polymer reactions, and crystallization processes.

Key aspects of the technique include:

- Absorption Spectra: This method measures the amount of infrared light absorbed by the sample at various wavelengths, providing insights into the presence and concentration of specific functional groups.

- Transmission Spectra: Here, the focus is on the amount of infrared light that passes through the sample, which can reveal changes in molecular structure and bonding.

Both methods are instrumental in elucidating the intricate details of molecular transformations, making in situ infrared spectroscopy a powerful tool in chemistry, materials science, and environmental science.

Applications

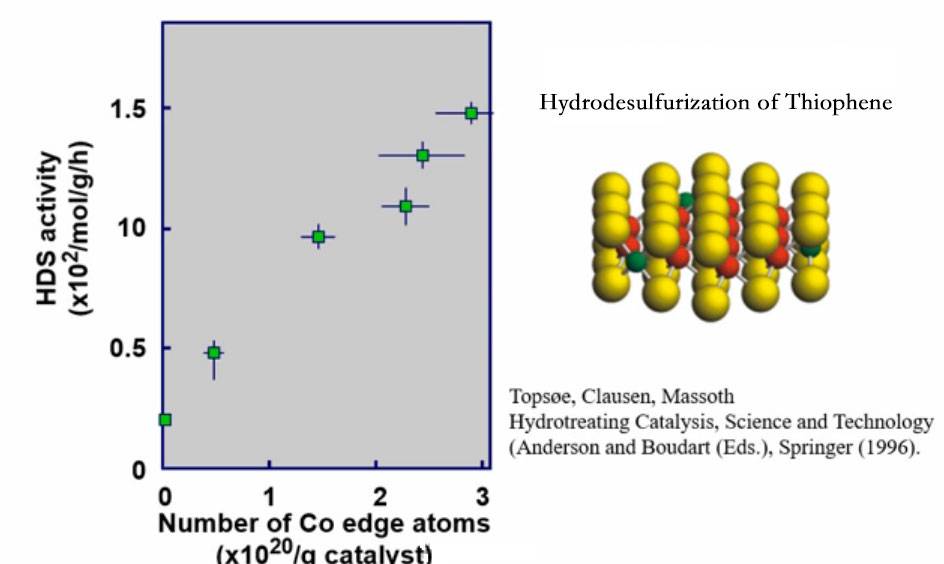

In situ IR analysis is a versatile technique that finds extensive applications across multiple scientific disciplines, including chemistry, materials science, and environmental science. This method is particularly valuable for catalyst characterization, where it provides insights into the active sites and the structural changes that occur during catalytic processes. By monitoring the reaction environment in real-time, researchers can elucidate the mechanisms of catalytic reactions and optimize catalyst performance.

In the realm of reaction kinetics, in situ IR spectroscopy allows for the direct observation of intermediates and transition states, offering a deeper understanding of reaction pathways and rates. This capability is crucial for developing new chemical processes and improving existing ones.

For polymer reactions, in situ IR analysis is instrumental in tracking the formation and degradation of polymer chains, providing critical data on molecular weight distribution and functional group transformations. This information is essential for the design and synthesis of new polymer materials with tailored properties.

Additionally, in situ IR spectroscopy plays a significant role in studying crystallization processes. By capturing the spectral changes during crystallization, researchers can identify the conditions that favor crystal growth and understand the underlying molecular mechanisms. This knowledge is vital for controlling the microstructure and properties of crystalline materials.

Moreover, in situ IR analysis extends its utility to environmental science, where it is employed to monitor the degradation of pollutants and the formation of byproducts in various environmental systems. This application aids in developing strategies for environmental remediation and pollution control.

In summary, in situ IR spectroscopy is a powerful tool that enhances our understanding of complex systems and processes, driving advancements in multiple scientific fields.

Sample Requirements

Quantity and Purity

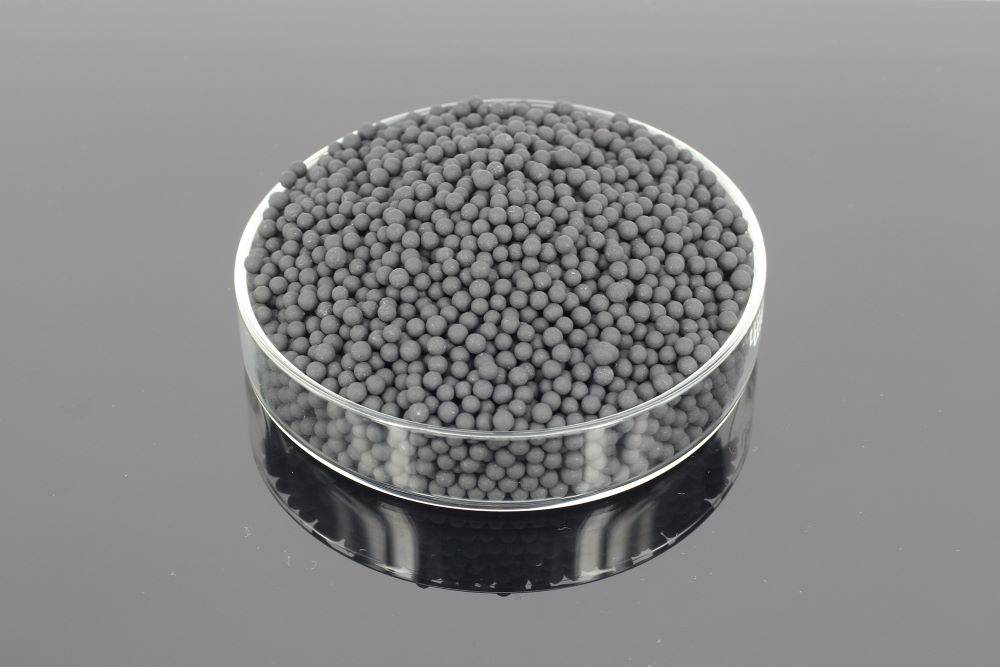

The sample requirements for in situ infrared spectroscopy (ISIS) are stringent, particularly concerning the quantity, purity, and homogeneity of the sample. To ensure the accuracy and reliability of the spectral data, the sample should weigh at least 1 gram. This ensures that there is sufficient material to provide a clear and distinct spectral profile, which is crucial for identifying and analyzing the molecular details, such as functional groups and structural changes.

High purity is equally critical, as even trace amounts of impurities can significantly alter the spectral data, leading to misinterpretations of the sample's chemical and physical properties. Therefore, the sample must be rigorously purified to remove any contaminants that could interfere with the spectral analysis.

Homogeneity is another key factor. The sample needs to be uniformly distributed to avoid any localized variations that could distort the spectral results. A homogeneous sample ensures that the recorded spectra accurately reflect the overall composition and properties of the material, rather than being skewed by localized inhomogeneities. This uniformity is particularly important in studies involving reaction kinetics, catalyst characterization, and polymer reactions, where subtle changes in the sample can have significant implications.

In summary, the combination of sufficient quantity, high purity, and homogeneity is essential for obtaining accurate and meaningful spectral data in in situ infrared spectroscopy.

Preparation Conditions

When preparing samples for in situ infrared spectroscopy, it is crucial to carefully define the pretreatment conditions, treatment temperature, and melting temperature. These parameters must be meticulously controlled to ensure that they remain below the sample's melting point. This precaution is essential to prevent any structural changes or degradation of the sample that could lead to inaccurate spectral data.

For instance, the treatment temperature should be set at a level that allows for the necessary chemical reactions or physical changes to occur without causing the sample to melt. This can be achieved by conducting preliminary thermal analyses to determine the sample's melting point and then setting the treatment temperature at a safe margin below this threshold.

Similarly, the melting temperature specified during the pretreatment process should be carefully calibrated to match the sample's physical properties. This ensures that the sample remains in a stable state throughout the analysis, allowing for precise and reliable data collection.

In summary, the meticulous control of pretreatment conditions, treatment temperature, and melting temperature is vital for the successful application of in situ infrared spectroscopy. By ensuring these parameters are set below the sample's melting point, researchers can obtain accurate and meaningful spectral data, facilitating a deeper understanding of the sample's chemical and physical properties.

Safety and Compatibility

When preparing samples for in situ infrared spectroscopy, it is crucial to ensure both safety and compatibility. The sample must not contain any corrosive compounds, as these can damage the instrumentation and pose safety risks to the operator. Additionally, the sample should not react with potassium bromide (KBr), which is commonly used as a matrix in the preparation of samples for infrared analysis.

To elaborate, corrosive compounds can lead to irreversible damage to the spectrometer's components, such as the optical elements and the sample holder. This not only affects the accuracy of the measurements but also can be costly to repair. Moreover, the presence of reactive substances that interact with KBr can alter the spectral data, leading to incorrect interpretations of the sample's properties.

| Aspect | Requirement |

|---|---|

| Corrosive Compounds | Must not be present; can damage instrumentation and pose safety risks. |

| Reactivity with KBr | Should not react; ensures accurate spectral data and prevents equipment damage. |

Ensuring that the sample meets these safety and compatibility criteria is essential for obtaining reliable and accurate infrared spectra.

Sample Preparation Methods

Tableting Method

The tableting method is a widely used technique for preparing solid powder samples for in situ infrared spectroscopy. This method involves the meticulous mixing of the sample powder with potassium bromide (KBr) or an alternative transparent matrix, which is then pressed into a compact tablet. This process is particularly advantageous for solid powder samples, as it ensures uniform dispersion and homogeneity, which are critical for obtaining accurate spectral data.

The use of KBr or similar matrices is essential because these materials are transparent to infrared radiation, allowing for the unobstructed transmission of IR light through the sample. This transparency ensures that the resulting spectra are not distorted by the matrix itself, thereby providing a clear and accurate representation of the sample's molecular structure and functional groups.

The pressing process typically involves applying high pressure to the mixture, which consolidates the powder into a solid, stable tablet. This tablet can then be placed directly into the IR spectrometer for analysis. The uniformity of the tablet ensures that the IR light interacts consistently with the sample across its entire surface, leading to reliable and reproducible spectral data.

In summary, the tableting method is a robust and effective preparation technique for solid powder samples, offering a combination of simplicity, reproducibility, and accuracy in spectral analysis.

Film Method

The film method is a versatile and effective technique for preparing samples in in situ infrared spectroscopy, particularly suited for liquid and solution samples. This method involves applying a sample solution onto an IR-transmitting substrate, typically made of materials like calcium fluoride or potassium bromide, which are transparent to infrared radiation. The solvent is then carefully evaporated, leaving behind a thin, uniform film of the sample on the substrate.

This preparation technique offers several advantages. Firstly, it ensures that the sample is in a consistent and reproducible form, which is crucial for accurate spectral analysis. The thin film allows for efficient transmission of infrared light, enabling detailed observation of molecular structures and functional groups. Additionally, the method is adaptable to a wide range of solvents, making it suitable for various types of samples, from organic compounds to complex mixtures.

Moreover, the film method facilitates the study of dynamic processes, such as chemical reactions and phase transitions, by allowing real-time monitoring. The ability to observe these processes in situ provides valuable insights into the kinetics and mechanisms involved, which is particularly useful in fields like catalysis, polymer science, and materials research.

In summary, the film method is a robust and flexible approach for sample preparation in in situ infrared spectroscopy, offering precise control and detailed analysis capabilities for liquid and solution samples.

Gas Cell Method

The Gas Cell Method is a specialized technique used for analyzing gaseous samples in in situ infrared spectroscopy. This method involves placing the gas sample into a dedicated gas cell designed to maintain optimal conditions for infrared analysis. The gas cell is typically constructed from materials that are transparent to infrared radiation, ensuring that the spectroscopic data collected is accurate and reliable.

Key Components of the Gas Cell Method

-

Gas Cell Design: The gas cell is engineered to withstand high pressures and temperatures, making it suitable for a wide range of gaseous samples. It often features windows made of materials like potassium bromide (KBr) or calcium fluoride (CaF2), which are transparent to infrared light.

-

Sample Introduction: The gas sample is introduced into the cell through a controlled process, ensuring that the gas is uniformly distributed within the cell. This is crucial for obtaining precise spectral data.

-

Pressure and Temperature Control: The gas cell is equipped with mechanisms to control both pressure and temperature. These controls are essential for replicating real-world conditions and for studying the effects of these variables on the gas sample's infrared absorption characteristics.

Advantages of the Gas Cell Method

-

High Sensitivity: The gas cell method allows for the detection of trace gases with high sensitivity, making it ideal for environmental monitoring and industrial applications.

-

Versatility: This method can be applied to a variety of gases, from simple diatomic molecules to complex organic vapors, providing detailed insights into their molecular structures and interactions.

-

Non-destructive Analysis: Since the gas cell method does not alter the sample, it is a non-destructive technique, preserving the integrity of the gas for further analysis or use.

By employing the gas cell method, researchers can gain valuable insights into the behavior of gaseous samples under different conditions, contributing to advancements in fields such as atmospheric science, catalysis, and industrial process control.

Pre-treatment for Noble Metal Catalysts

Pre-treatment of noble metal catalysts is a critical step in ensuring accurate and meaningful spectral data collection. This process typically involves subjecting the catalysts to a controlled environment of hydrogen and oxygen. The primary objective of this pre-treatment is to prevent the oxidation of the noble metal surfaces, which can significantly alter the catalyst's performance and spectral characteristics. Additionally, this treatment helps in minimizing the adsorption of unwanted molecules onto the catalyst surface, thereby maintaining its purity and reactivity.

Following the hydrogen/oxygen treatment, the catalyst is purged with an inert gas, such as argon or nitrogen. This purging step is essential to remove any residual gases and ensure a clean environment for the subsequent spectral analysis. The inert gas effectively flushes out any remaining reactive species, providing a stable and inert atmosphere that is conducive to accurate spectral measurements.

Once the pre-treatment and purging steps are complete, the catalyst is ready for spectral signal collection. This phase involves utilizing in situ infrared spectroscopy to capture detailed spectral signals, which provide insights into the catalyst's structural and functional properties. The collected data can then be analyzed to understand the catalyst's behavior under different conditions, aiding in the optimization of catalytic processes and the development of more efficient catalysts.

Related Products

- No Demolding Lab Infrared Press Mold for Laboratory Applications

- Lab Infrared Press Mold

- XRF & KBR plastic ring lab Powder Pellet Pressing Mold for FTIR

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR