Introduction to Handheld XRF Analyzers

Handheld XRF Analyzers have revolutionized the mining and exploration sectors by providing lab-quality results on-site. These innovative devices enable faster decision-making and operational efficiency, transforming the way we conduct mineral exploration, ore grade control, and waste processing. Learn about their key features, applications, and how they contribute to more sustainable mining practices. Delve into the technological advancements that have made these analyzers a game-changer and discover the factors to consider when choosing the right device for your needs. Explore the future trends expected in Handheld XRF technology and be prepared to embrace the next wave of advancements in the field.

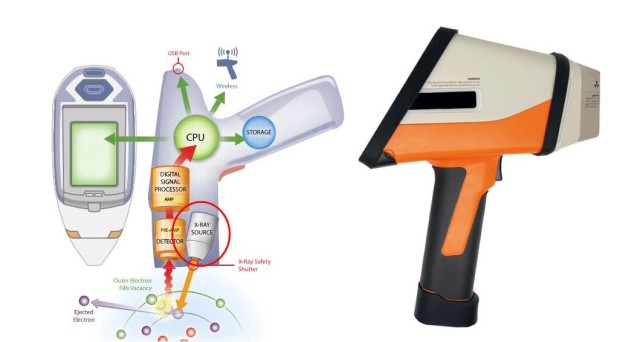

Key Features of Handheld XRF Analyzers

Handheld XRF analyzers have revolutionized the field of metal analysis and quality control with their advanced features and user-friendly operation. These devices are equipped with high-performance micro X-ray tubes, SDD (Silicon Drift Detector) technology, and intelligent software, which together contribute to their superior analytical performance and ease of use.

High-Performance Micro X-Ray Tubes

The core of these analyzers is the high-performance micro X-ray tube, which generates the X-rays used for elemental analysis. These tubes are designed to be compact yet powerful, ensuring that the analyzers can deliver accurate results even in the field. The X-ray tube's efficiency and stability are crucial for achieving consistent and reliable measurements, making it an essential component for handheld XRF devices.

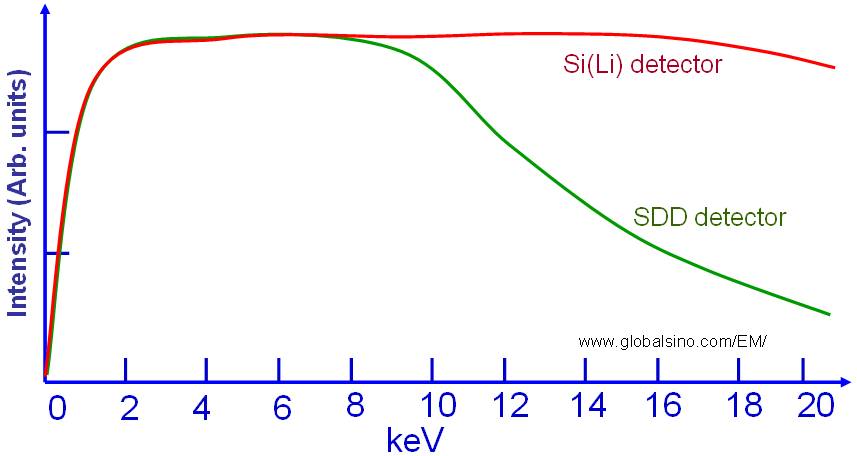

SDD Detectors

SDD detectors are another critical feature of handheld XRF analyzers. Compared to traditional Si-PIN detectors, SDD detectors offer significantly higher count rates and improved resolution. This technology allows for faster analysis and better detection limits, enabling the analyzers to identify elements with greater precision. The superior performance of SDD detectors also means that users can obtain lab-quality results in a matter of seconds, right on-site.

Intelligent Software

The software in handheld XRF analyzers is designed to be intuitive and user-friendly, requiring minimal training for operators. This intelligent software not only simplifies the operation of the device but also enhances its analytical capabilities. It includes advanced algorithms that optimize the analysis process, ensuring accurate and reliable results. Additionally, the software allows for easy data export, making it convenient for users to share and analyze their findings.

Superior Analytical Performance

The combination of high-performance micro X-ray tubes, SDD detectors, and intelligent software results in superior analytical performance. Handheld XRF analyzers can analyze a wide range of elements simultaneously, without the need for complicated sample preparation. This capability is particularly beneficial in various applications, including metal analysis, scrap metal recycling, and quality control in manufacturing processes.

Conclusion

Handheld XRF analyzers are an invaluable tool for on-site metal analysis and quality control. Their key features, such as high-performance micro X-ray tubes, SDD detectors, and intelligent software, contribute to their superior analytical performance and user-friendly operation. These devices enable rapid, accurate, and non-destructive analysis, making them an ideal choice for a wide range of industries and applications.

Applications in Mining and Beyond

Handheld XRF Analyzers have revolutionized the mining industry by providing fast and accurate on-site analysis, which is crucial for various applications including mineral exploration, ore grade control, and waste processing. These devices use XRF technology to deliver lab-quality results with minimal sample preparation, making them indispensable tools in the harsh environments of mining and exploration.

Hardrock Mining Analysis

In hardrock mining, Handheld XRF analyzers are essential for scrutinizing ore samples, whether in open pits or deep underground mines. These analyzers provide the precision needed to oversee processes, ensure quality, and make crucial operational decisions, such as maintaining grade control. By enabling real-time grade control, these devices help in evaluating the feasibility of lower grade resources, identifying localized high-grade enrichments, and defining the boundaries between ore and waste. This capability not only enhances the management of run-of-mine stockpiles but also ensures consistent blending and mill feed quality, leading to substantial cost reductions and operational efficiency.

Ore Grade Control

The control of ore grade is vital in the mining process. Handheld XRF analyzers, such as the Terra In-line XRF analyzer 700, can be configured to analyze ore on conveyor belts, significantly improving analysis efficiency and ensuring the consistency of ore grade. This not only saves on raw material costs but also enhances production efficiency, allowing for the rapid recovery of equipment investment.

More Applications

Beyond mining, the In-line700 series of analyzers can also perform real-time detection of solid film thickness, such as metal coatings, and conduct online composition analysis of liquids or fluids. This versatility extends their utility across various industries, including the copper foil industry and electroplating.

Enhanced Productivity and Sustainability

Time efficiency is a critical factor in mining operations. Handheld XRF analyzers allow for swift qualitative screenings directly in the field, facilitating the clear demarcation of ore and waste boundaries and reducing the unpredictability of excavation. By providing reliable data on-site, these analyzers minimize the need for outsourcing samples to external labs, thereby reducing turnaround times and laboratory expenses.

Intelligent Software

AXR analyzers come equipped with intelligent software that features a user-friendly interface, allowing customization of data fields and user profiles to suit specific business needs. The AXRSPEC PC software enables remote operation of the analyzer, and WiFi capability allows for seamless transfer and remote viewing of sample readings, enhancing operational flexibility and efficiency.

Applications

Handheld XRF analyzers are utilized in a variety of mining applications, including mineral exploration, core analysis for exploration drilling, geochemical testing and mapping, mine face or pit-face analysis, waste processing and metal recovery, and ore grade control. They are also used in silver ore mining and as an alternative to mineral lab testing.

In conclusion, Handheld XRF Analyzers are pivotal in modern mining operations, offering a fast, accurate, and versatile solution for a range of applications. Their ability to provide immediate, on-site analysis with minimal preparation not only enhances operational efficiency but also supports sustainable and cost-effective mining practices.

Enhancing Productivity and Sustainability

In the dynamic field of mining and exploration, the integration of advanced technology is crucial for maximizing productivity and promoting sustainable practices. Handheld XRF analyzers, such as the AXR, offer a revolutionary approach to on-site analysis, significantly enhancing operational efficiency and environmental sustainability.

Rapid On-Site Analysis and Cost Reduction

The AXR handheld XRF analyzer is equipped with a 5W x-ray tube and a graphene window detector, enabling it to detect elements at concentrations equal to or lower than typical naturally occurring values in the Earth's crust. This exceptional sensitivity allows for the rapid identification of significant findings, reducing the duration of exploration campaigns. By facilitating prompt geochemical analysis of outcrops and soils, the AXR empowers mining teams to map uncharted territories swiftly. This rapid analysis eliminates the waiting time for test results and reduces expenses associated with external lab tests, saving not only days and weeks but also substantial financial resources.

Enhanced Grade Control and Resource Management

In hardrock mining, the AXR plays a pivotal role in scrutinizing ore samples, providing the precision needed for reliable data. This data is crucial for overseeing processes, ensuring quality, and making crucial operational decisions. The analyzer enables real-time grade control, allowing for the evaluation of lower grade resources, identification of localized high-grade enrichments, and clear definition of the boundaries between ore and waste. These capabilities not only enhance the management of run-of-mine stockpiles but also provide guidance for blasting, excavation, and ore handling operations, ensuring consistent blending and mill feed quality.

Sustainability and Environmental Impact

The AXR's non-destructive testing capabilities contrast sharply with traditional destructive methods like acid and fire assay. By preserving the integrity of the samples, the AXR contributes to more sustainable mining practices. This non-destructive approach not only reduces the environmental impact but also allows for further analysis of the same sample if necessary, optimizing resource use and minimizing waste.

Conclusion

The AXR handheld XRF analyzer exemplifies how cutting-edge technology can significantly enhance productivity in mining operations while promoting sustainable practices. By reducing reliance on external labs, facilitating rapid on-site analysis, and enabling precise grade control, the AXR not only boosts efficiency but also aligns with environmental stewardship. As the mining industry continues to evolve, tools like the AXR will undoubtedly play a crucial role in shaping a more productive and sustainable future.

Technological Advancements in Handheld XRF Analyzers

Handheld XRF (X-Ray Fluorescence) analyzers have revolutionized the field of metal analysis and quality control, offering rapid, accurate, and non-destructive testing capabilities. Recent advancements in technology have further enhanced the capabilities of these devices, particularly through the integration of the fundamental parameters method (FP) and the analysis of light elements.

The fundamental parameters method is a mathematical approach that allows for the accurate quantification of elements in a sample without the need for calibration standards. This method uses fundamental physical parameters such as absorption coefficients, fluorescence yields, and X-ray cross-sections to calculate the concentration of elements in the sample. The FP method is particularly beneficial in situations where standard samples are not available or when analyzing a wide range of sample types. By incorporating this method, handheld XRF analyzers can provide lab-quality results within seconds, making them an ideal tool for on-site analysis and quality control in various industries, including metal processing, mining, and recycling.

Another significant advancement in handheld XRF technology is the ability to analyze light elements such as magnesium, aluminum, silicon, and sulfur. Traditionally, XRF analyzers have been limited to the analysis of heavier elements due to the lower energy of characteristic X-rays emitted by lighter elements, which are more easily absorbed by the sample matrix. However, with the development of advanced X-ray tubes and detectors, such as Silicon Drift Detectors (SDD), handheld XRF analyzers can now accurately detect and quantify these light elements. This capability is particularly important in industries where the presence of light elements can significantly affect the properties and quality of materials, such as in alloy production and petrochemical analysis.

The combination of the FP method and the analysis of light elements in handheld XRF analyzers has expanded their application range and improved their analytical performance. These devices can now provide comprehensive elemental analysis, from light elements to heavy metals, with high precision and speed. This makes them invaluable tools for various applications, including scrap metal sorting, factory incoming material inspection, production quality control, and rapid identification of alloy grades.

Moreover, the integration of advanced electronics and state-of-the-art mathematical algorithms in handheld XRF analyzers ensures that they deliver the ultimate quality of measurement within a couple of seconds. The simplicity of operation, with features like touch screen displays and one-click measurements, allows users to obtain lab-quality chemistry with minimal training and no sample preparation, regardless of the sample's shape or size.

In conclusion, the technological advancements in handheld XRF analyzers, particularly the implementation of the fundamental parameters method and the analysis of light elements, have significantly enhanced their capabilities and utility across various industries. These advancements not only improve the efficiency and accuracy of on-site analysis but also contribute to cost savings and enhanced productivity in quality control processes.

Choosing the Right Handheld XRF Analyzer

Selecting the appropriate Handheld XRF Analyzer is crucial for ensuring efficiency and accuracy in various mining and exploration projects. The choice depends on specific needs, budget, and the nature of the project. Here, we will explore the key factors to consider when choosing a handheld XRF analyzer.

Analytical Capabilities

The primary function of a handheld XRF analyzer is to provide rapid, non-destructive analysis of elemental composition. For mining applications, it is essential to choose an analyzer that can accurately measure the elements of interest in the ore. For instance, the XRF 200 Benchtop Gold analyzer offers precise assessment of gold content, which is vital for quality control and pricing in gold mining operations.

Speed and Efficiency

In mining operations, time is a critical factor. The Terra In-line XRF analyzer 700, for example, can be configured to analyze ore on a conveyor belt, significantly improving analysis efficiency. This real-time analysis capability helps in maintaining the consistency of ore grade, thereby saving costs and enhancing production efficiency.

Versatility

A versatile handheld XRF analyzer can be used across different stages of mining and for various materials. The In-line 700 series not only performs solid online composition analysis but also detects solid film thickness and analyzes liquids or fluids. This versatility makes it suitable for a wide range of applications, from ore sorting to quality control in metal processing.

Ease of Use

The practicality and ease of use of a handheld XRF analyzer are crucial, especially in field conditions. The XRF 200 precious metal analyzers are designed for retail environments and are factory-calibrated, ready for use upon arrival. The closed-beam design ensures safety, with no x-ray exposure to customers or operators.

Non-Destructive Testing

Non-destructive testing capabilities are vital in preserving the integrity of samples. Unlike destructive methods like acid and fire assay, handheld XRF analyzers allow for testing without harming the sample. This is particularly important in precious metal analysis where the value of the sample must be preserved.

Cost Considerations

Budget is a significant factor in choosing a handheld XRF analyzer. While high-end models offer advanced features and greater accuracy, there are cost-effective options that provide reliable performance for basic needs. It is important to balance the initial investment with the long-term benefits, such as improved efficiency and reduced labor costs.

In conclusion, choosing the right handheld XRF analyzer involves considering analytical capabilities, speed, versatility, ease of use, non-destructive testing capabilities, and cost. By carefully evaluating these factors, mining and exploration projects can select an analyzer that best fits their specific requirements, enhancing their operational efficiency and profitability.

Future Trends in Handheld XRF Technology

Handheld XRF (X-Ray Fluorescence) technology has been a cornerstone in metal analysis and grade identification, offering rapid, accurate, and non-destructive testing capabilities. As industries continue to evolve, the demand for more efficient and integrated solutions is driving significant advancements in handheld XRF technology. Here, we explore the emerging trends and future developments expected in this field, focusing on improvements in accuracy, speed, and integration with other technologies.

Enhanced Accuracy and Precision

One of the primary areas of focus in the development of handheld XRF analyzers is the enhancement of accuracy and precision. Manufacturers are continually improving the technology to achieve results comparable to traditional laboratory methods like fire assay. This involves the use of advanced algorithms and high-performance detectors, such as Silicon Drift Detectors (SDD), which offer superior count rates and resolution compared to older technologies like SiPIN detectors. These advancements not only improve the detection limits for elements but also ensure more reliable and precise measurements, crucial for industries dealing with precious metals and critical materials.

Increased Speed and Efficiency

The speed of analysis is another critical aspect being addressed in the latest handheld XRF devices. Modern analyzers are designed to provide lab-quality results within seconds, thanks to sophisticated electronics and mathematical algorithms. This rapid analysis capability is particularly beneficial in high-throughput environments such as scrap metal recycling and factory incoming material inspections. The trend towards faster analysis not only enhances productivity but also reduces labor costs and turnaround times, making real-time decision-making more feasible.

Integration with Other Technologies

Integrating handheld XRF technology with other analytical tools and software is a growing trend that promises to expand its applications and improve its functionality. For instance, integrating XRF with machine learning algorithms can enhance the predictive capabilities of the devices, allowing for more accurate grade predictions and defect identification. Additionally, the integration with IoT (Internet of Things) enables remote monitoring and data analysis, which is particularly useful in large-scale operations and in environments where continuous monitoring is required.

Adaptability and Versatility

Future handheld XRF analyzers are expected to become more versatile, capable of analyzing a wider range of materials and conditions. This includes the ability to analyze not only solid metals but also liquids and powders, expanding the scope of applications in industries such as pharmaceuticals and environmental testing. The adaptability of these devices will also be enhanced by improved user interfaces and rugged designs that allow for use in various harsh environments without compromising performance.

Conclusion

The future of handheld XRF technology looks promising, with ongoing advancements aimed at improving accuracy, speed, and integration with other technologies. These developments will not only enhance the efficiency and effectiveness of metal analysis but also expand the applicability of handheld XRF analyzers across various industries. As the technology continues to evolve, it will remain a vital tool for quality control, scrap metal recycling, and many other applications, ensuring that industries can meet the demands of a rapidly changing market.

Related Products

Related Articles

- Effective Preparation of Samples for XRF Analysis via Pressed Pellets Method

- How to Choose the Right XRF Pellet Press for Your Needs

- Techniques for Sample Preparation in X-Ray Fluorescence Analysis: Pressed and Loose Powder Methods

- A Guide To PREPARE SAMPLES FOR XRF ANALYSIS

- Unlocking the Power of XRF Spectrometer Modules: A Comprehensive Guide