XRF Pellet Preparation Methods

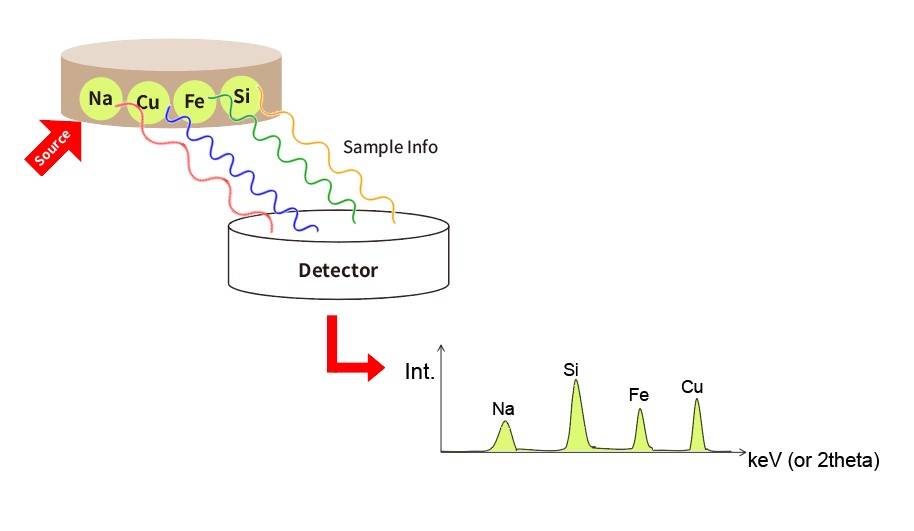

X-ray fluorescence (XRF) analysis requires the preparation of uniform, high-quality pellets for accurate analysis. To achieve this, there are several XRF pellet preparation methods available, including hydraulic, manual, and automated presses.

Table of Contents

Hydraulic Presses

Hydraulic presses are the most efficient method of preparing XRF pellets. They provide high throughput and consistent pressure for reliable an

d accurate results. With these presses, the sample is mixed with a binder/grinding aid and placed in a die, and then the press applies pressure to the die to form the pellet. Hydraulic presses are ideal for laboratories that require high throughput and consistent pressure to produce pellets.

Manual Presses

Manual presses are a more affordable option but require more time and effort to create pellets. They are operated by hand and require the operator to apply pressure to the die manually. Manual presses are ideal for laboratories with a lower budget and lower throughput requirements.

Automated Presses

Automated presses offer the best of both worlds, providing high throughput and consistent pressure with minimal operator intervention. These presses are operated by a computer and can produce pellets quickly and efficiently. They are ideal for laboratories that require high throughput and consistent pressure with minimal operator intervention.

When choosing an XRF pellet press, it is important to consider several factors, including the type of sample you will be analyzing, the required pellet size and shape, and the level of throughput you need. Ultimately, the choice of XRF pellet press will depend on your specific needs, budget, and level of experience.

In conclusion, the preparation of XRF pellets is a crucial step in X-ray fluorescence analysis. Choosing the right XRF pellet press can significantly impact the accuracy and reliability of your results. Hydraulic presses are the most efficient, manual presses are a more affordable option, and automated presses offer the best of both worlds. By considering several factors and selecting the right XRF pellet press for your needs, you can ensure accurate and reliable analysis of your samples.

Advantages of Using Pressed Pellets for XRF Analysis

X-ray Fluorescence spectroscopy (XRF) is highly sensitive to the preparation of the sample material. The following are the advantages of using pressed pellets for XRF analysis:

Improved Sample Homogeneity

Pressed pellets offer improved sample homogeneity, which is essential for accurate and reproducible results. With pressed pellets, the sample is compressed into a solid pellet with a uniform density, reducing the likelihood of segregation and uneven distribution of elements within the sample.

Reduced Particle Size Effects

Particle size effects can significantly impact XRF analysis, leading to erroneous results. Pressed pellets help to reduce particle size effects by breaking down the sample particles to a uniform size and shape. This reduction in particle size results in a more consistent and reproducible analysis.

Improved Precision and Accuracy

Pressed pellets offer improved precision and accuracy when compared to loose powders. The uniform density and homogeneity of the sample in a pressed pellet lead to more accurate and reproducible results.

Increased Stability and Durability

Pressed pellets are more stable and durable than loose powders, which can be easily disturbed by air currents or changes in temperature and humidity. The pressing process compacts the sample particles, resulting in a more stable and durable sample for analysis.

In conclusion, choosing the right XRF pellet press is crucial to achieving accurate and reproducible results. Pressed pellets offer several advantages over loose powders, including improved sample homogeneity, reduced particle size effects, improved precision and accuracy, and increased stability and durability. By considering the type of materials being analyzed, the required sample throughput, and the available budget, laboratories can select the best XRF pellet press for their needs and achieve optimal results.

Correct Load for XRF Pellet Pressing

X-ray fluorescence (XRF) analysis is a common technique used in materials science and geology to analyze the elemental composition of solid samples. XRF pellet pressing is a crucial sample preparation technique used in XRF analysis. The correct load for XRF pellet pressing depends on several factors, such as the type of sample, the desired pellet size, and the type of press used.

Factors to Consider

To ensure accurate and reliable results, factors such as the maximum load capacity, the type of die set used, the ease of use and maintenance, and the cost should be considered when choosing an XRF pellet press. Advanced features such as automated pressing, digital pressure control, and interchangeable die sets may also be important for some applications. Ultimately, the choice of XRF pellet press will depend on the specific needs and budget of the user, as well as the level of precision and accuracy required for the analysis.

Pressing Powder Samples

The purpose of pressing powder samples is to create a solid material that does not fall apart after the removal of the load. The correct load required to achieve a fully bonded pellet depends greatly upon the materials involved. Hard and brittle materials generally have a harder time binding to each other than softer materials. Powders which do not flow easily in the die will also make for more difficult samples since they cannot achieve sufficient packing for adhesion to occur.

KBr Pellet Making

KBr pellets are easy to make if a few simple rules are followed. First, heat the anvils and the body of the die set before making your pellet. This makes them as dry as possible. Second, use dry KBr powder. Third, make sure that the anvils, the die set, and the powder are all the same temperature. A load of 10 tonnes applied through a 13 mm diameter pellet die is usually more than adequate for the task.

Geologic Samples

Geological samples are often full of very hard, brittle minerals, and their ability to form pellets is quite poor. They are usually ground to a very fine powder and mixed with a cellulose or boric acid binding agent before proceeding. These agents lubricate the flow of particles in the die and help them to adhere. Most samples will form a suitable pellet at a load of 10-20 tonnes to form pellets in a 40 mm die. However, loads of up to 40 tonnes are occasionally needed for very difficult samples.

Food and Plant-Based Materials

Food and plant-based materials will often contain oils that dissociate and seep out under high pressure. Unless you actually want to collect the oil, these materials should be pressed at lower tonnages (4 tonnes or less).

Conclusion

In conclusion, choosing the right XRF pellet press is crucial for obtaining accurate and reliable results in X-ray fluorescence (XRF) analysis. By selecting the right XRF pellet press and applying the correct load, users can ensure that their samples are properly prepared for XRF analysis, leading to more accurate and reliable results.

Manual vs Automatic XRF Pellet Press

X-ray fluorescence (XRF) analysis is a widely used technique in many laboratories, and the quality of the results depends heavily on the quality of the sample preparation. One of the essential steps in XRF analysis is creating a pellet from the sample. There are two primary types of XRF pellet presses: manual and automatic. Here, we will discuss the differences between these two types of presses.

Manual XRF Pellet Press

A manual XRF pellet press is a cost-effective option that requires the user to manually load the sample and apply pressure to create a pellet. Manual presses are usually straightforward to use, making them an excellent option for labs with limited budgets or those with less complex sample requirements. These presses are available in a variety of sizes and capacities, so they can be used for both small-scale and large-scale testing. Moreover, manual presses are very versatile and can be used for many sample preparation techniques.

Automatic XRF Pellet Press

An automatic XRF pellet press is an automated press that uses an electric motor to drive the pump and electric switches to open and close the relief valve. These presses offer greater precision and consistency, making them ideal for labs with high throughput requirements and complex sample matrices. Automatic presses often come with software that allows users to monitor and adjust the compression force, ensuring high-quality pellets every time. Automatic hydraulic presses are often used for industrial XRF applications and other laboratory sample manipulation activities.

How to Choose Between Manual and Automatic XRF Pellet Press

The decision between a manual or automatic XRF pellet press comes down to the specific needs of your laboratory. Several factors need to be considered, including budget, sample complexity, and throughput requirements. Manual presses are generally more cost-effective and straightforward to use, making them a good option for labs with limited budgets or those with less complex sample requirements. However, if your workflow relies on pressed samples and your lab staff will need to produce them recurrently, they might find a manual hydraulic press to be quite laborious. In such cases, automatic presses will likely be more convenient and enable a quicker pace of work.

Automatic presses offer greater precision and consistency, making them ideal for labs with high throughput requirements and complex sample matrices. These presses often come with software that allows users to monitor and adjust the compression force, ensuring high-quality pellets every time. Moreover, automatic presses often improve the workflow in busy laboratories, as they can operate autonomously, allowing the technician to get to work on other tasks.

Final Thoughts

In conclusion, choosing the right XRF pellet press for your laboratory needs is crucial for accurate and reliable results. Manual and automatic XRF pellet presses both have their advantages and disadvantages, and the decision between the two ultimately depends on the specific needs of your lab. By considering factors such as budget, sample complexity, and throughput requirements, you can select the right press to ensure accurate and reliable results for your research.

Checklist for making XRF pellets

To ensure accurate and reliable results for your XRF analysis, it is crucial to choose the right XRF pellet press that meets your specific requirements. Here is a checklist that you can use to help you choose the right XRF pellet press:

Pressing Force

The pressing force of the pellet press must be adequate to form a dense pellet without damaging the sample. If the force is too low, the pellet will be too loose, resulting in poor reproducibility. On the other hand, if the force is too high, it will damage the sample and may not produce reliable results.

Die Size

The die size should be compatible with your sample size and the XRF instrument. If the die size is too small, you won't be able to fit enough sample in the pellet. If it's too large, the sample may not be properly compressed, leading to inconsistent results.

Ease of Operation

The press should be easy to operate, and the process should be quick and straightforward. This will save time and reduce the chance of errors. Look for a press with simple controls, clear instructions, and easy-to-use accessories.

Material Compatibility

The press should be made of materials that are compatible with the samples being analyzed to prevent contamination. For example, if you are analyzing organic samples, you should choose a press made of materials that do not react with organic compounds.

Cleaning Ease

The press should be easy to clean to prevent cross-contamination between samples. Look for a press with removable parts that can be easily cleaned and sterilized.

Durability

The pellet press must be robust and long-lasting to withstand the rigors of daily use. Look for a press made of durable materials that can withstand high pressures and repeated use.

Cost

The cost of the pellet press should be reasonable and within your budget. However, do not compromise on the quality of the press for cost.

By considering these factors, you can choose the right XRF pellet press that meets your specific requirements and obtain accurate and reliable results for your XRF analysis.

Factors to Consider When Choosing a Lab Press

Choosing the right XRF pellet press is crucial for accurate and reliable analysis. Here are the key factors to consider when selecting a lab press:

Sample Type and Pressure Requirements

Consider the type of sample you will be working with and the pressure required to create the pellet. Some pellet presses are designed for soft samples and lower pressures, while others can handle hard samples and higher pressures. Choosing the right press for your sample type is crucial to ensure accurate and consistent analysis.

Pellet Size and Die Diameter

The size of the pellet and the diameter of the die are also important factors to consider. The size of the pellet should match the size of the sample cup used in the XRF instrument. Some lab presses can accommodate a wide range of different-sized or customized dies. Choosing the right press with the appropriate die diameter is important to ensure compatibility with your XRF instrument.

Ease of Use and Maintenance

Consider the ease of use and maintenance of the lab press. A user-friendly and low-maintenance pellet press can save time and reduce the risk of errors. It is important to choose a lab press that is easy to operate and maintain.

Cost and Availability of Spare Parts and Consumables

Evaluate the cost and availability of spare parts and consumables for the lab press. It is important to select a pellet press that fits your budget and is compatible with the available resources. Consider the cost of spare parts and consumables, as well as their availability, to ensure that you can maintain and repair your lab press as needed.

In summary, choosing the right XRF pellet press for your needs requires careful consideration of the sample type, pressure requirements, pellet size, ease of use and maintenance, and cost. By taking these factors into account, you can ensure that your XRF analysis is accurate, efficient, and reliable.

Related Products

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- XRF & KBR plastic ring lab Powder Pellet Pressing Mold for FTIR

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

- Manual Lab Heat Press