Yes, aluminum can be sintered, but the process is significantly more challenging than it is for materials like iron or copper. Success hinges on overcoming the tenacious, naturally forming oxide layer on the surface of the aluminum powder particles, which acts as a barrier to the metallic bonding required for successful sintering.

While technically possible, sintering aluminum is a specialized process that requires advanced techniques to disrupt its persistent oxide layer. For many applications, traditional manufacturing methods like casting or machining remain more practical and cost-effective.

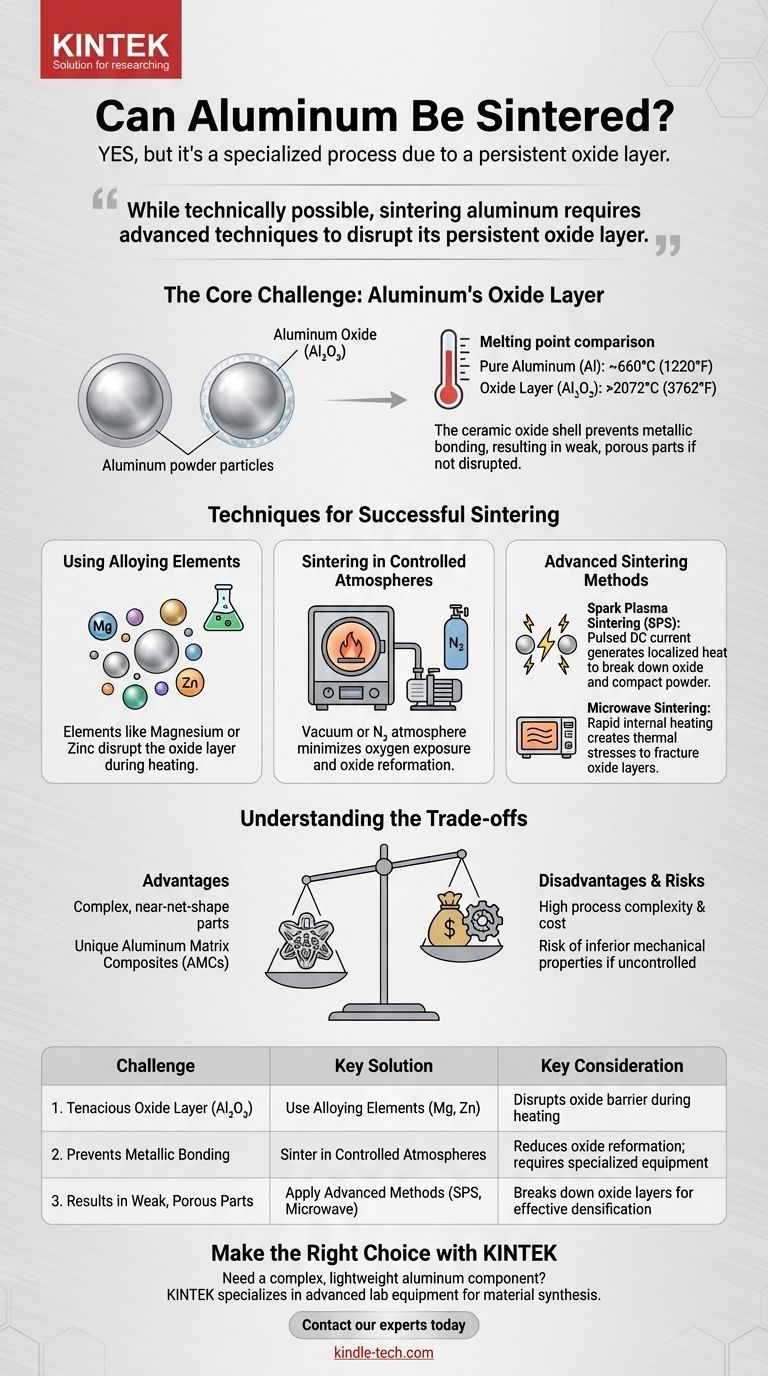

The Core Challenge: Aluminum's Oxide Layer

To understand why sintering aluminum is difficult, you must first understand the behavior of the material at a microscopic level. The primary obstacle is not the aluminum itself, but the ceramic shell that encases every powder particle.

What is the Oxide Layer?

Aluminum is highly reactive with oxygen. When exposed to air, it instantly forms a very thin, hard, and chemically stable layer of aluminum oxide (Al₂O₃), also known as alumina.

This oxide layer is self-passivating, meaning it protects the underlying aluminum from further oxidation, which is why aluminum parts are so corrosion-resistant.

Why it Prevents Sintering

The core problem is the vast difference in melting points. Pure aluminum melts at approximately 660°C (1220°F), while its oxide layer, Al₂O₃, melts at over 2072°C (3762°F).

During a conventional sintering process, the furnace temperature is raised high enough to cause atomic diffusion between metal particles, fusing them together. With aluminum, the temperature required to sinter the metal is far too low to break down the surrounding high-temperature ceramic oxide shells. The particles remain isolated from each other.

The Impact on Mechanical Properties

If this oxide barrier is not adequately removed or disrupted, the resulting part will be a weakly bonded collection of powder particles rather than a solid metallic component. This leads to high porosity, poor mechanical strength, and brittleness, making the part unreliable for most engineering applications.

Techniques for Successfully Sintering Aluminum

Engineers have developed several specialized strategies to overcome the oxide layer challenge. These methods are essential for producing dense, strong sintered aluminum components.

Using Alloying Elements

One common strategy is to mix the aluminum powder with specific alloying elements. Elements like magnesium, zinc, or lithium can help disrupt the oxide layer during heating, allowing the pure aluminum particles to make contact and bond.

Sintering in Controlled Atmospheres

Conducting the sintering process in a vacuum or a nitrogen-based atmosphere minimizes the oxygen available, which can help reduce the reformation of the oxide layer during heating. However, this does not remove the oxide that is already present on the powder.

Advanced Sintering Methods

Newer, more advanced technologies are often more effective for aluminum.

- Spark Plasma Sintering (SPS): This method uses a pulsed DC current to generate plasma between particles. This creates intense, localized heat that can physically break down the oxide layers while simultaneously applying pressure to compact the powder, enabling rapid and effective densification.

- Microwave Sintering: This technique uses microwave energy to heat the material internally. This rapid and volumetric heating can create thermal stresses that help fracture the oxide layers, promoting better bonding.

Understanding the Trade-offs

Choosing to sinter aluminum involves balancing its potential benefits against significant process complexities and costs. It is not a universally superior method.

The Advantages of Sintered Aluminum

When executed correctly, sintering allows for the creation of complex, near-net-shape parts with minimal material waste, which can be difficult or expensive to achieve with machining.

It also opens the door to creating unique aluminum matrix composites (AMCs) by mixing aluminum powder with ceramic reinforcements to achieve specific properties not possible with standard alloys.

The Disadvantages and Risks

The primary disadvantage is process complexity and cost. The specialized equipment and controlled environments required for successful aluminum sintering are more expensive than conventional powder metallurgy setups.

There is also a significant risk of producing parts with inferior mechanical properties if the process is not perfectly controlled. The final density and strength can be highly sensitive to powder quality, atmosphere purity, and temperature profiles.

Making the Right Choice for Your Goal

Your decision to use sintering for an aluminum part must be driven by your final application and design priorities.

- If your primary focus is creating complex, lightweight, near-net-shape parts and performance is critical: Sintering is a viable path, but requires significant investment in process development or partnership with a specialized provider.

- If your primary focus is maximum strength, fatigue resistance, or cost-effectiveness for simple geometries: Traditional methods like CNC machining from billet, die casting, or extrusion are almost always the superior choice.

- If your primary focus is developing novel materials with unique properties (e.g., AMCs): Advanced sintering techniques like Spark Plasma Sintering are often the best or only method available.

Understanding these fundamental challenges and solutions is the key to determining if sintering is the correct manufacturing path for your specific application.

Summary Table:

| Challenge | Key Solution | Key Consideration |

|---|---|---|

| Tenacious Oxide Layer (Al₂O₃) | Use Alloying Elements (Mg, Zn) | Disrupts the oxide barrier during heating |

| Prevents Metallic Bonding | Sinter in Controlled Atmospheres | Reduces oxide reformation; requires specialized equipment |

| Results in Weak, Porous Parts | Apply Advanced Methods (SPS, Microwave) | Breaks down oxide layers for effective densification |

Need to produce a complex, lightweight aluminum component? Sintering aluminum is a highly specialized process. KINTEK specializes in advanced lab equipment and consumables for challenging material synthesis. Our expertise can help you navigate the complexities of aluminum sintering to achieve high-performance results. Contact our experts today to discuss your project and discover the right solution for your laboratory needs.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- How does a high-power adjustable speed mixer function in dynamic corrosion testing? Enhance Refractory Simulation

- What are the primary advantages and disadvantages of the plasma spraying technique? Expert Process Insights

- What three factors cause melting? Understand Temperature, Pressure, and Impurities

- What is KBR technology? The Blueprint for Industrial-Scale Chemical Production

- Why is a constant temperature shaker utilized in Methylene Blue adsorption experiments? Ensure Precise Data Integrity

- How is filter press capacity calculated? Unlock Accurate Sizing for Your Specific Slurry

- What equation do you use to calculate the heat required to melt a sample? Master the Heat of Fusion Formula

- What are the heat treatment critical factors? Master Temperature, Time, and Cooling Rate