Yes, nanomaterials can pose significant health hazards, and this is a central area of study within the field of nanotoxicology. Unlike their bulk-sized counterparts, the unique physicochemical properties of materials at the nanoscale—particularly their tiny size and high surface area-to-volume ratio—allow them to interact with biological systems in complex and sometimes detrimental ways. The primary routes of concern for exposure are inhalation, ingestion, and dermal contact, with inhalation representing the most direct path for systemic absorption.

The potential hazard of a nanomaterial is not defined by its chemical composition alone. Instead, risk is a direct function of its specific physical properties—including size, shape, surface charge, and coating—which dictate how it interacts with cells, tissues, and organs.

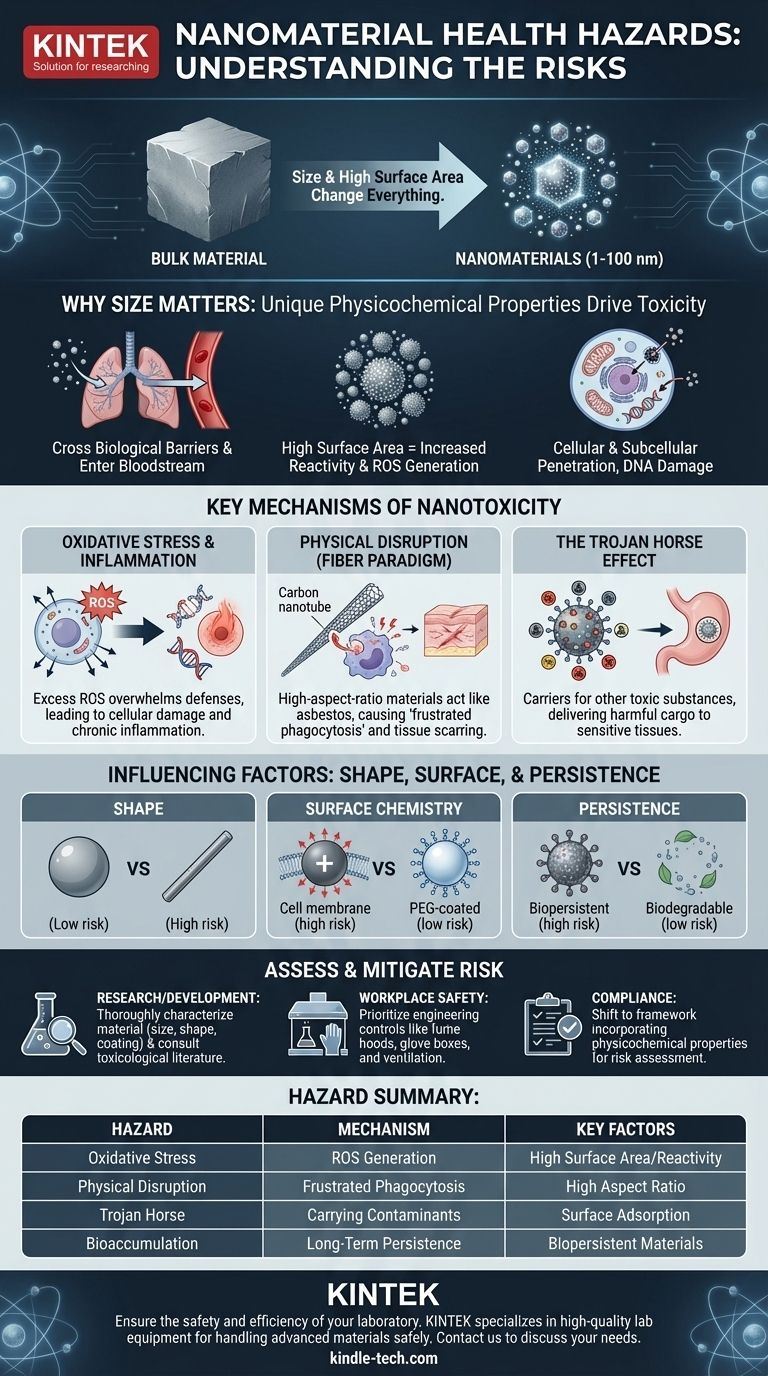

Why Size and Scale Change Everything

The fundamental reason nanomaterials present a novel toxicological challenge is that the rules of classical toxicology do not always apply. Their behavior is governed by properties that are insignificant at a larger scale.

The Ability to Cross Biological Barriers

A nanoparticle's extremely small size (typically defined as 1-100 nanometers in at least one dimension) allows it to bypass many of the body's natural defense mechanisms.

They can be inhaled deep into the alveolar regions of the lungs, where they can cross the air-blood barrier and enter the bloodstream. Once in circulation, they can travel throughout the body and accumulate in secondary organs like the liver, spleen, and even the brain.

Furthermore, nanoparticles are small enough to enter individual cells and even subcellular compartments like the mitochondria and the nucleus, where they can directly interfere with critical cellular functions and damage DNA.

The High-Surface-Area Effect

For a given mass, a collection of nanoparticles has a vastly greater surface area than a single block of the same material. This dramatically increases their chemical and biological reactivity.

This high surface area provides more sites for catalytic reactions that can generate harmful molecules, such as Reactive Oxygen Species (ROS), which are a primary driver of nanotoxicity.

Key Mechanisms of Nanotoxicity

While the effects can be complex, most nanomaterial-induced damage can be traced back to a few core biological mechanisms.

Oxidative Stress and Inflammation

The most common mechanism of nanotoxicity is the induction of oxidative stress. Many nanomaterials, due to their high surface reactivity, can trigger an overproduction of ROS within cells.

This excess of ROS overwhelms the cell's natural antioxidant defenses, leading to damage of lipids, proteins, and DNA. This cellular damage, in turn, can trigger a persistent inflammatory response, which is a key factor in the development of chronic diseases.

Physical Disruption and the "Fiber Paradigm"

Certain nanomaterials, particularly those with a high aspect ratio (long and thin) like carbon nanotubes, can cause physical, mechanical damage to cells. This is analogous to the well-understood mechanism of asbestos fibers.

When immune cells called macrophages attempt to engulf these long fibers, they are unable to fully enclose them. This process, known as "frustrated phagocytosis," triggers a chronic release of inflammatory signals, leading to tissue scarring and potentially cancer, such as mesothelioma.

The "Trojan Horse" Effect

Nanoparticles can act as carriers for other toxic substances. They can adsorb heavy metal contaminants from their manufacturing process or pollutants from the environment onto their large surface.

By penetrating deep into the body's tissues, these nanoparticles can then deliver their toxic cargo to sensitive areas that would otherwise be protected, acting as a "Trojan Horse" for other harmful compounds.

Understanding the Trade-offs: Not All Nanomaterials Are Equal

It is a critical mistake to categorize all "nanomaterials" as uniformly hazardous. Toxicity is highly specific to the material's properties.

The Role of Shape and Structure

Spherical nanoparticles generally pose a different, often lower, risk than fibrous or needle-shaped ones. As mentioned, high-aspect-ratio nanomaterials raise concerns due to the fiber paradigm, while spheres are more easily managed by the body's clearance mechanisms.

The Influence of Surface Chemistry

The surface of a nanoparticle dictates its interaction with cell membranes. A positively charged surface, for instance, can be more disruptive to the negatively charged cell membrane, leading to higher toxicity.

Conversely, engineers can deliberately apply surface coatings (like polyethylene glycol, or PEG) to make a nanoparticle more "biocompatible." This can effectively shield a reactive core material, rendering it biologically inert and reducing its toxicity.

Biodegradability and Persistence

The risk profile changes dramatically depending on whether a nanoparticle is biopersistent or biodegradable. Materials that do not break down, such as gold nanoparticles or carbon nanotubes, can accumulate in the body over time, raising concerns about long-term effects.

In contrast, materials like some zinc oxide or iron oxide nanoparticles can dissolve or be metabolized by the body. While this can release ions that may have their own toxicity, it avoids the problem of long-term bioaccumulation.

How to Assess and Mitigate Nanomaterial Risk

A proactive approach requires evaluating nanomaterials not as a single category, but based on their specific characteristics and the context of their use. This allows for a more accurate and effective risk management strategy.

- If your primary focus is research or product development: Thoroughly characterize your specific nanomaterial (size, shape, surface charge, coating) and consult nanotoxicology literature relevant to that material class before proceeding.

- If your primary focus is workplace safety: Prioritize engineering controls like fume hoods, glove boxes, and specialized ventilation to minimize inhalation exposure, which is the most significant risk pathway.

- If your primary focus is regulatory compliance or safety assessment: Shift from a purely chemical-based hazard assessment to a framework that incorporates the critical physicochemical properties that define a nanomaterial's unique risk profile.

By understanding the principles that govern nanobio interactions, we can innovate responsibly and harness the immense benefits of nanotechnology while safeguarding human health.

Summary Table:

| Potential Hazard | Mechanism | Key Factors |

|---|---|---|

| Oxidative Stress & Inflammation | Generation of Reactive Oxygen Species (ROS) | High surface area, surface reactivity |

| Physical Disruption | Frustrated phagocytosis (e.g., carbon nanotubes) | High aspect ratio, fiber-like shape |

| Trojan Horse Effect | Carrying toxic contaminants into the body | Surface adsorption, ability to cross biological barriers |

| Bioaccumulation | Long-term persistence in organs | Biopersistent materials (e.g., gold nanoparticles) |

Ensure the safety and efficiency of your laboratory when working with nanomaterials. KINTEK specializes in providing high-quality lab equipment and consumables designed to handle advanced materials safely. From fume hoods and glove boxes to specialized ventilation systems, our products help mitigate exposure risks and protect your team. Let our experts help you build a safer lab environment—contact us today to discuss your specific needs!

Visual Guide

Related Products

- Nickel Foam for Industrial and Laboratory Applications

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Advanced Engineering Fine Ceramics Aluminum Nitride (AlN) Ceramic Sheet

- Optical Window Glass Substrate Wafer Sheets Zinc Sulfide ZnS Window

- Zinc Selenide ZnSe Optical Window Glass Substrate Wafer and Lens

People Also Ask

- What are two disadvantages of metal? Understanding Corrosion and Weight Limitations

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- What are the disadvantages of using metal? Understanding Corrosion, Weight, and Cost Challenges

- What is the end product of plastic waste? The Alarming Truth About Its Final Destination

- What is the difference between metallic and non-metallic coating? A Guide to Sacrificial vs. Barrier Protection