At their core, optical coatings work by using incredibly thin layers of material to manipulate light waves through a principle called wave interference. These engineered films, often thinner than a wavelength of light, cause reflected light waves to either cancel each other out or reinforce each other, thereby controlling how much light is transmitted or reflected.

The essential function of an optical coating is to create controlled interference between light waves. By precisely engineering the thickness and refractive index of one or more thin layers, we can dictate whether light is transmitted through a surface or reflected from it.

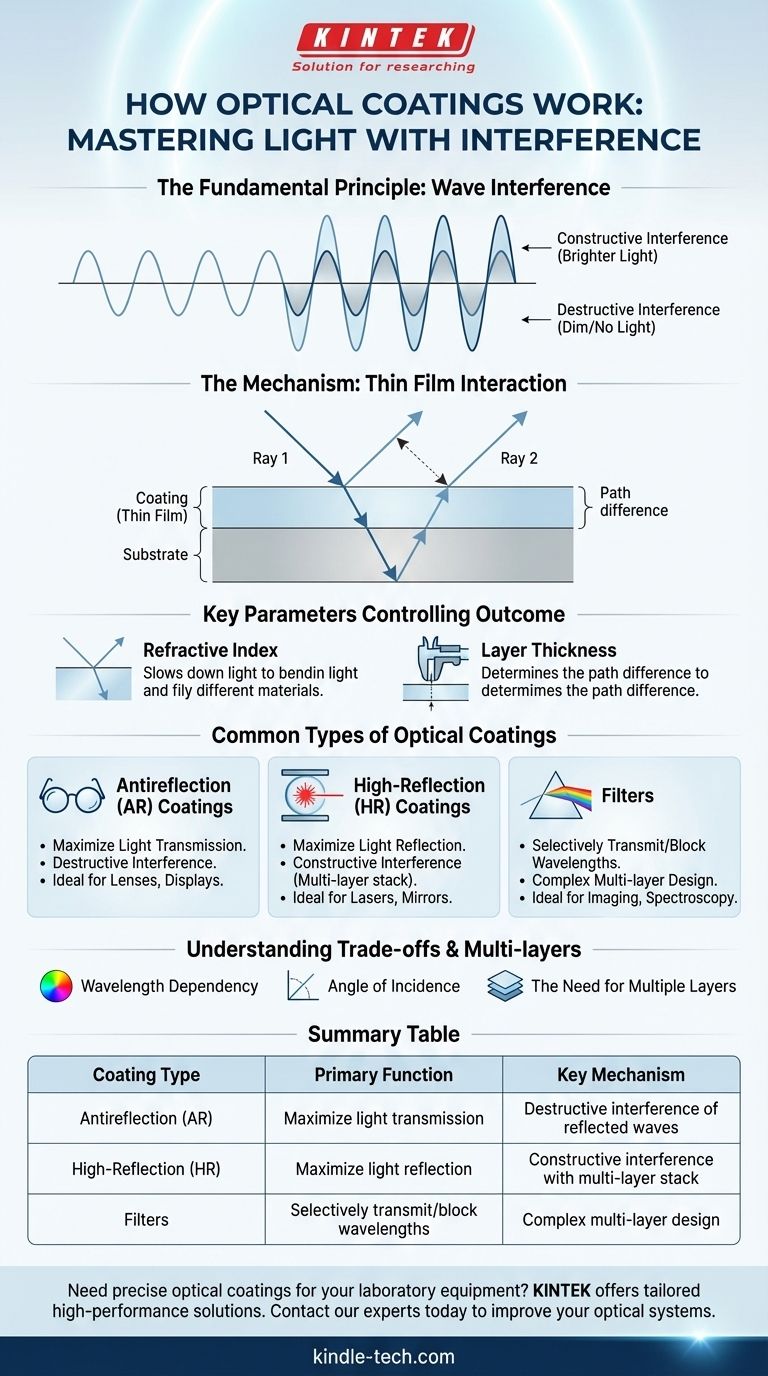

The Fundamental Principle: Wave Interference

To understand optical coatings, you must first understand that light behaves as a wave. Like ripples in a pond, light waves have peaks and troughs. The way these waves interact is the key to a coating's function.

Light as a Wave

Every light wave has a phase (the position of its peaks and troughs) and an amplitude (the height of its peaks, which relates to its intensity). When multiple waves meet, they combine.

The Concept of Interference

When light waves combine, they "interfere" with one another.

- Constructive Interference: If the peaks of two waves align, their amplitudes add up, resulting in brighter light.

- Destructive Interference: If the peaks of one wave align with the troughs of another, they cancel each other out, resulting in dim or no light.

How a Thin Film Creates Interference

When light strikes a coated surface, a portion of it reflects from the top surface of the coating. The rest of the light enters the coating, and a portion of that reflects from the bottom surface (the interface with the underlying material, or substrate).

We now have two separate reflected waves. The wave that reflected from the bottom surface has traveled a longer path. This path difference is what allows us to control how the two waves interfere.

Key Parameters That Control the Outcome

The specific outcome of this interference—and thus the coating's function—is governed by two critical parameters.

Refractive Index

The refractive index of a material describes how much it slows down light. The difference in refractive index between the air, the coating material, and the substrate determines how much light is reflected at each interface.

Layer Thickness

The thickness of the coating layer is the most critical design parameter. It is engineered to control the path length difference between the two reflected light waves. By tuning this thickness precisely, we can ensure the waves are perfectly out of phase (for cancellation) or perfectly in phase (for reinforcement) for a specific wavelength of light.

Common Types of Optical Coatings

These principles are applied to create several types of standard coatings.

Antireflection (AR) Coatings

AR coatings are the most common type, used on everything from eyeglasses to camera lenses. Their goal is to maximize light transmission.

They work by creating destructive interference for reflected light. The ideal single-layer AR coating has a thickness of one-quarter of the light's wavelength and a specific refractive index. This causes the two reflected waves to emerge 180 degrees out of phase, effectively canceling each other out.

High-Reflection (HR) Coatings

Also known as dielectric mirrors, HR coatings are designed to maximize light reflection. They are essential for applications like lasers and certain optical instruments.

These coatings achieve their effect through constructive interference. They are built from a stack of many alternating layers of high and low refractive index materials. Each layer is designed to add its reflection in phase with the others, building up to reflectivities that can exceed 99.9%.

Filters

Filters use the same principles to selectively transmit or reflect specific ranges of wavelengths. By using complex multi-layer designs, engineers can create shortpass filters (which transmit short wavelengths), longpass filters (which transmit long wavelengths), or bandpass filters (which transmit only a narrow band of wavelengths).

Understanding the Trade-offs

Optical coatings are highly engineered solutions, and their performance is subject to specific constraints.

Wavelength Dependency

A coating is always optimized for a specific wavelength or range of wavelengths. An AR coating designed for green light will be less effective for red or blue light. Broadband coatings that work across the visible spectrum require more complex and expensive multi-layer designs.

Angle of Incidence

Performance is also highly dependent on the angle at which light strikes the surface. A coating designed for light hitting head-on (at 0 degrees) will not perform as well for light coming in at a steep angle, because the path length difference inside the film changes.

The Need for Multiple Layers

As mentioned in the reference materials, a single layer is often insufficient. Multi-layer coatings provide far greater design freedom. They allow engineers to create coatings that work over a broader range of wavelengths and angles or to achieve extremely high levels of reflection or transmission that are impossible with a single film.

Making the Right Choice for Your Goal

Your choice of coating depends entirely on what you need to do with light.

- If your primary focus is maximizing light transmission (e.g., lenses, displays): You need an Antireflection (AR) coating optimized for your operational wavelength range.

- If your primary focus is creating a highly reflective surface (e.g., laser mirrors, beam splitters): You need a High-Reflection (HR) coating, which uses a multi-layer stack for constructive interference.

- If your primary focus is isolating a specific color or band of light (e.g., imaging, spectroscopy): You need a specialized filter coating designed to selectively pass or block the desired wavelengths.

By understanding these core principles, you can demystify optical coatings and see them as powerful tools for the precise control of light.

Summary Table:

| Coating Type | Primary Function | Key Mechanism |

|---|---|---|

| Antireflection (AR) | Maximize light transmission | Destructive interference of reflected waves |

| High-Reflection (HR) | Maximize light reflection | Constructive interference with multi-layer stack |

| Filters | Selectively transmit/block wavelengths | Complex multi-layer design for wavelength control |

Need precise optical coatings for your laboratory equipment? KINTEK specializes in high-performance lab equipment and consumables, offering optical solutions that enhance light control for your specific applications. Our expertise ensures optimal performance for your lenses, lasers, and spectroscopic instruments. Contact our experts today to discuss how we can improve your optical systems with tailored coating solutions.

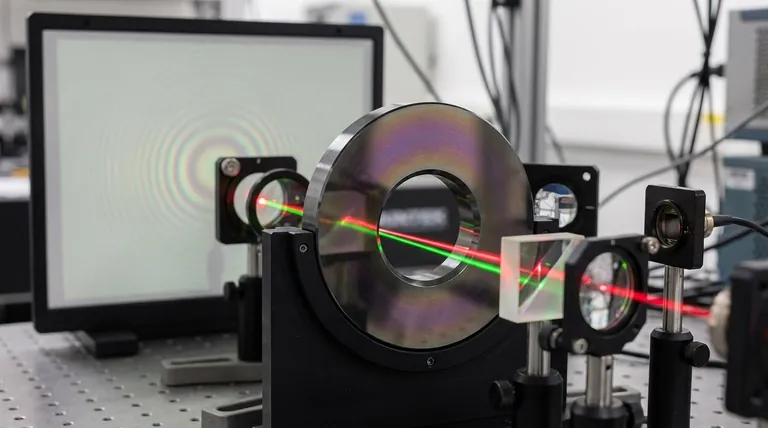

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- Custom PTFE Teflon Parts Manufacturer Adjustable Height Flower Basket

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- Platinum Sheet Electrode for Laboratory and Industrial Applications

People Also Ask

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What is the vapor phase material? Unlock Faster, Denser Sintering with SPS Technology

- What is sputtering in thin film coating application? A Guide to High-Performance Film Deposition

- Why don't we use carbon nanotubes? Unlocking the Potential of a Supermaterial

- What are the steps involved in the sputtering process? A Guide to High-Quality Thin Film Deposition

- How is graphene made and what is the process? A Guide to Top-Down vs. Bottom-Up Methods

- What is the difference between single-crystal and polycrystalline diamond? Choose the Right Material for Your Lab

- What materials are needed for thin film? Metals, Oxides, and Semiconductors for Your Application