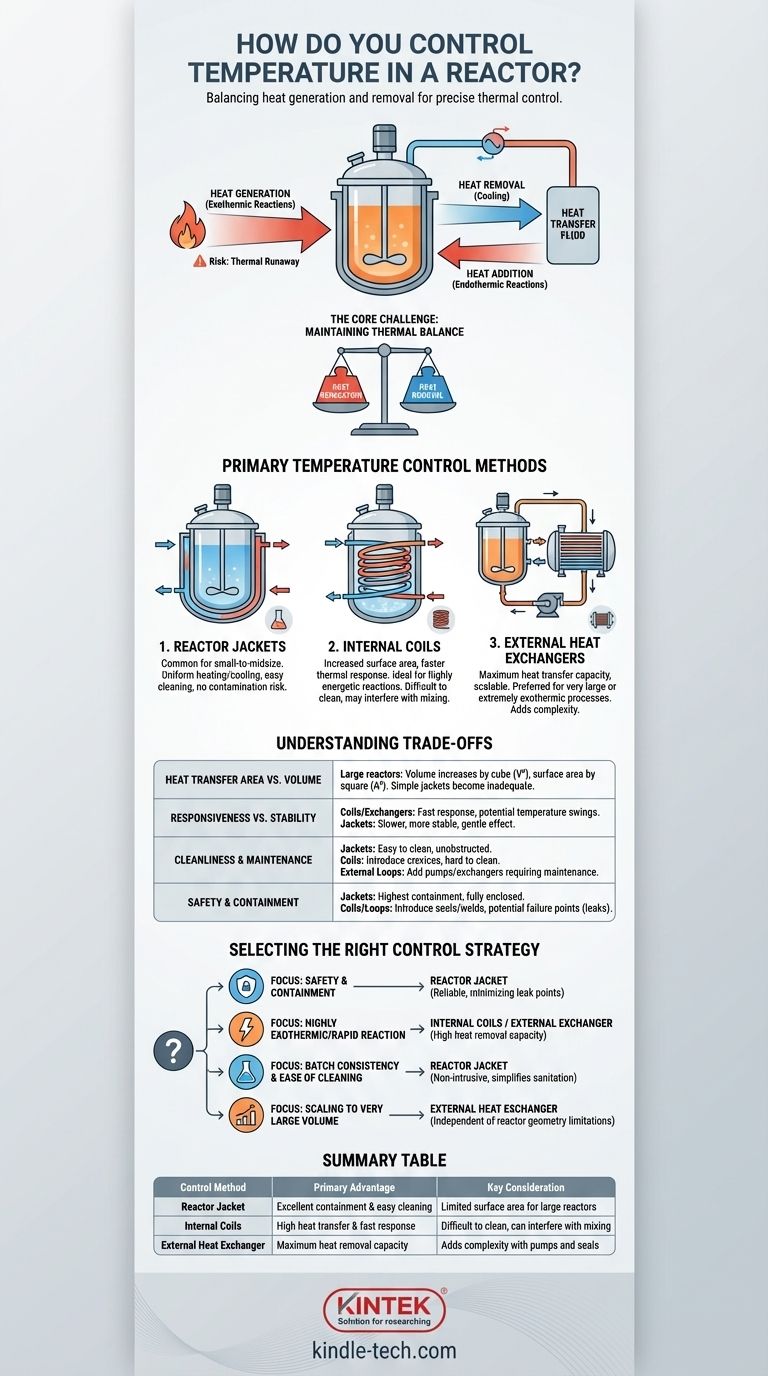

In practice, reactor temperature is controlled by actively adding or removing heat using a heat transfer fluid that flows through a specific mechanical system. The most common systems are external reactor jackets, internal coils, or external heat exchangers, each with distinct advantages for managing the heat generated or consumed by the chemical reaction inside.

The core challenge of reactor temperature control is not merely heating or cooling, but maintaining a precise thermal balance. The chosen method must safely manage the reaction's energy while accounting for the physical limitations of heat transfer, especially as reactor size increases.

The Core Challenge: Balancing Reaction Heat

At its heart, temperature control is a heat-balance problem. For a reaction to remain at a stable temperature, the rate of heat removal must equal the rate of heat generation.

The Problem of Exothermic Reactions

Most industrial reactions of concern are exothermic, meaning they release heat. If this heat is not removed faster than it is generated, the temperature will rise.

This temperature increase accelerates the reaction rate, which in turn generates even more heat. This dangerous feedback loop, known as thermal runaway, can lead to a catastrophic failure of the reactor.

The Need for Endothermic Reactions

Some reactions are endothermic, meaning they require a constant input of energy to proceed at a desirable rate.

In these cases, the temperature control system must efficiently supply heat to prevent the reaction from slowing down or stopping altogether, ensuring process efficiency and consistent product quality.

Primary Temperature Control Methods

The choice of hardware is fundamental to achieving control. The three primary methods each use a surface to transfer heat between the reaction mass and a separate heat transfer fluid (like water, steam, or thermal oil).

Reactor Jackets

A reactor jacket is essentially a shell or second wall built around the main vessel, creating a hollow space for the heat transfer fluid to circulate.

They are the most common solution for small-to-midsize reactors. Their primary advantage is providing uniform heating or cooling without any internal components, which simplifies cleaning and eliminates potential contamination.

Internal Coils

Internal coils are pipes installed inside the reactor itself, through which the heat transfer fluid flows.

This method dramatically increases the available surface area for heat transfer compared to a jacket alone. Coils provide a much faster thermal response and are excellent for managing highly energetic reactions, but they can interfere with mixing and are difficult to clean.

External Heat Exchangers

In this setup, a pump continuously circulates the reactor contents out of the vessel, through a separate, highly efficient heat exchanger, and back into the reactor. This is often called a "pump-around loop."

This approach offers the most significant heat transfer capacity, as the size of the external exchanger is not limited by the reactor's geometry. It is the preferred method for very large reactors or extremely exothermic processes.

Understanding the Trade-offs

Selecting a temperature control method involves critical trade-offs between performance, safety, and operational complexity. The right choice is dictated by the specific demands of the chemical process.

Heat Transfer Area vs. Reaction Volume

This is the most critical concept in reactor scale-up. As a reactor gets larger, its volume increases by a cube (power of 3), while its surface area only increases by a square (power of 2).

This means a large reactor has much less available jacket surface area relative to its heat-generating volume. This is why a simple jacket that works for a 100-liter reactor will be completely inadequate for a 10,000-liter reactor running the same reaction.

Responsiveness vs. Stability

Internal coils and external exchangers react very quickly to changes in temperature, which is crucial for stopping a potential runaway. However, they can also cause rapid temperature swings.

Jackets are slower and more stable, providing a "gentle" heating or cooling effect. This can be advantageous for sensitive reactions but is a liability when rapid cooling is a safety requirement.

Cleanliness and Maintenance

Jackets provide an unobstructed internal vessel that is easy to clean, a critical requirement in pharmaceutical or food-grade applications.

Internal coils introduce crevices and surfaces that are very difficult to clean thoroughly. External loops add a pump and exchanger to the list of equipment requiring regular maintenance.

Safety and Containment

A jacketed reactor offers the highest level of containment, as the reaction mass is fully enclosed.

Internal coils and external pump-around loops introduce additional seals, welds, and potential failure points (like a pump seal failure) that could lead to a loss of containment.

Selecting the Right Control Strategy

Your choice must be a deliberate decision based on your primary process goal. An effective control strategy is not a one-size-fits-all solution.

- If your primary focus is process safety and maximum containment: A well-designed reactor jacket is often the most reliable and robust choice, minimizing potential leak points.

- If your primary focus is managing a highly exothermic or rapid reaction: Internal coils or an external heat exchanger are essential for providing the high heat removal capacity required.

- If your primary focus is batch consistency and ease of cleaning: A jacketed reactor is superior due to its non-intrusive design that prevents product buildup and simplifies sanitation.

- If your primary focus is scaling a process to a very large volume: An external heat exchanger provides heat transfer capability that is independent of the reactor's unfavorable surface-area-to-volume ratio.

Ultimately, mastering temperature control is the foundation for a safe, efficient, and predictable chemical process.

Summary Table:

| Control Method | Primary Advantage | Key Consideration |

|---|---|---|

| Reactor Jacket | Excellent containment & easy cleaning | Limited surface area for large reactors |

| Internal Coils | High heat transfer & fast response | Difficult to clean, can interfere with mixing |

| External Heat Exchanger | Maximum heat removal capacity | Adds complexity with pumps and seals |

Struggling to maintain precise temperature control in your chemical processes? KINTEK specializes in high-performance lab equipment and consumables for laboratory needs. Our reactor systems are designed with optimal temperature control in mind, helping you achieve thermal balance, enhance safety, and improve batch consistency. Contact us today (#ContactForm) to discuss how our solutions can bring precision and reliability to your laboratory.

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is the function of a stirred tank reactor in Fenton-TiO2? Enhance Dye Degradation & Mass Transfer

- Why is the use of a sealed reactor necessary during the mechanical alloying of Fe-Cr-Ni-Mn-N alloys? High-Purity Results

- What is the function of a high-temperature and high-pressure reactor? Optimize Fe3O4 Synthesis for Boron Adsorbents

- How are fixed-bed reactors used to evaluate perovskite oxygen carriers? Master material kinetics and durability.

- What role does a high-pressure static autoclave play in simulating the service environment for 310H stainless steel?

- Why is a customized limiting mold used in conjunction with a High-Pressure Reactor? Achieve Precise scCO2 Foaming

- What roles do the high-pressure reactor and PTFE liner play in MOF synthesis? Achieve Pure, High-Quality Crystals

- What are the advantages of using lab-scale batch reactors for screening hydrothermal process parameters? Find the key!