To test a lithium battery, the most basic method is to use a multimeter to check its voltage. Connect the multimeter's red probe to the positive terminal and the black probe to the negative terminal. A healthy, fully charged single-cell lithium-ion battery should read around 4.2 volts, while its nominal voltage is typically 3.7 volts.

While a voltage check is a useful first step, it only reveals the battery's current state of charge, not its actual health. A true assessment of whether a battery is "good" requires testing its capacity (how much energy it holds) and inspecting it for physical damage.

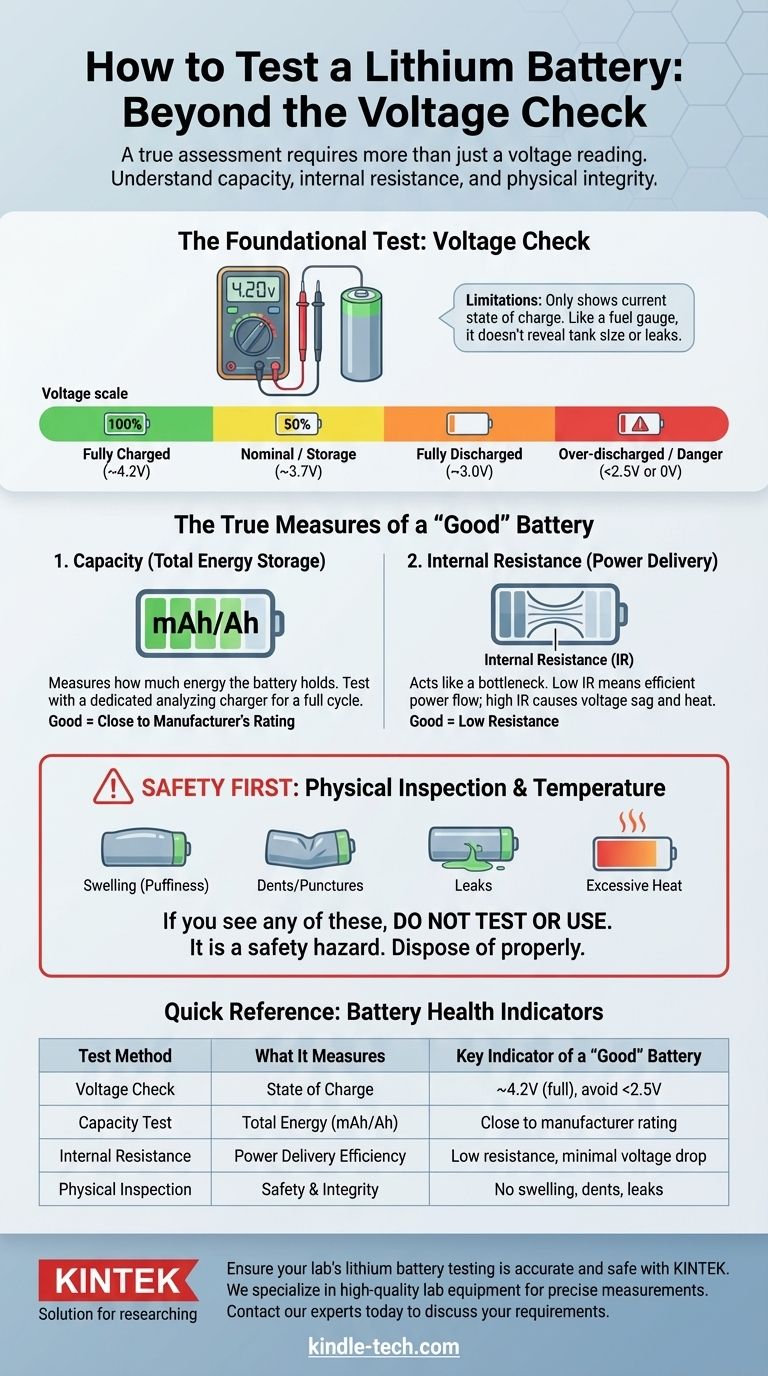

The Foundational Test: Measuring Voltage

A simple voltage test is the starting point for any battery assessment. It's a quick indicator of the battery's immediate status and can help you spot a completely dead or over-discharged cell.

How to Use a Multimeter

First, set your multimeter to the "DC Voltage" setting, choosing a range that can accommodate at least 5 volts (the 20V setting is common).

Carefully touch the red probe to the battery's positive (+) terminal and the black probe to the negative (-) terminal. The screen will display the battery's current voltage.

Interpreting the Voltage Reading (for a single 3.7V cell)

The voltage reading tells you the battery's current charge level, not its long-term health.

- ~4.2V: The battery is 100% charged.

- ~3.7V: This is the nominal, or storage, voltage, representing roughly 50% charge.

- ~3.0V: The battery is considered fully discharged.

- Below 2.5V: The battery has been over-discharged. This can cause permanent damage and significantly reduce its capacity and lifespan.

- 0V: The battery is either completely dead or, more likely, its internal protection circuit has tripped due to a fault like a short circuit or over-discharge.

The Critical Limitation of a Voltage Test

Voltage alone is a poor indicator of a battery's true condition. A worn-out battery might read 4.2V right off the charger but then die within minutes of use.

Think of it like a car's fuel gauge. The gauge can say "full," but it can't tell you if the fuel tank has a leak or if the engine is so inefficient it will burn through that fuel in half the expected time.

The True Measures of a "Good" Battery

To understand if a battery is truly good, you must look beyond voltage and measure the two factors that define its performance and reliability.

1. Capacity (Total Energy Storage)

Capacity, measured in milliamp-hours (mAh) or amp-hours (Ah), is the single most important metric for battery health. It tells you how much energy the battery can actually store and deliver.

The most reliable way to test capacity is with a dedicated analyzing charger. These devices perform a full charge-discharge-charge cycle, precisely measuring how much energy the battery delivers during the discharge phase. A "good" battery should have a tested capacity close to its manufacturer's rating.

2. Internal Resistance (Power Delivery)

Internal resistance (IR) acts like a bottleneck for energy flow. A low IR allows the battery to deliver power easily, while a high IR causes the voltage to sag under load and generates excess heat.

As a battery ages and degrades, its internal resistance increases. This is why an old phone battery might show 100% charge but shut off the moment you try to open an app. High IR is a definitive sign of a degraded battery, even if its capacity seems acceptable.

Common Pitfalls and Warning Signs

Ignoring key warning signs because of a "good" voltage reading is a common and dangerous mistake.

Always Perform a Physical Inspection

Before you connect any meter, look at the battery. If you see any swelling (puffiness), dents, punctures, or leaks, the battery is a safety hazard. Do not attempt to charge or use it. Dispose of it immediately at a proper recycling facility.

Monitor Temperature

A healthy battery should remain cool or slightly warm during normal charging and use. If a battery becomes uncomfortably hot to the touch, it's a sign of high internal resistance or another internal fault. Stop using it immediately.

How to Apply This to Your Goal

Your testing method should align with what you need the battery to do.

- If your primary focus is a quick spot-check: Use a multimeter to ensure the voltage is within a safe range (above 3.0V for a single cell) and perform a thorough physical inspection.

- If your primary focus is verifying runtime for a device: You must measure the true capacity using an analyzing charger with a test function.

- If your primary focus is building a multi-cell battery pack: Measuring both capacity and internal resistance is critical to ensure all cells are matched and will share the load safely and evenly.

- If you see any physical damage or swelling: Do not test the battery. Its electrical properties are irrelevant because it is no longer safe to use.

Ultimately, understanding a battery's capacity and physical integrity, not just its voltage, is the key to assessing its true health and reliability.

Summary Table:

| Test Method | What It Measures | Key Indicator of a 'Good' Battery |

|---|---|---|

| Voltage Check | State of Charge | ~4.2V (fully charged); avoid <2.5V (over-discharged) |

| Capacity Test | Total Energy (mAh/Ah) | Tested capacity is close to manufacturer's rating |

| Internal Resistance | Power Delivery Efficiency | Low resistance; minimal voltage drop under load |

| Physical Inspection | Safety & Integrity | No swelling, dents, punctures, or leaks |

Ensure your lab's lithium battery testing is accurate and safe with KINTEK.

Whether you're developing new battery technology or need reliable power for your laboratory instruments, precise testing is non-negotiable. KINTEK specializes in high-quality lab equipment and consumables, providing the tools you need to accurately measure battery capacity, internal resistance, and overall health.

Let us help you power your innovations safely and efficiently.

Contact our experts today to discuss your specific laboratory battery testing requirements.

Visual Guide

Related Products

- Button Battery Case for Battery Lab Applications

- Laboratory Test Sieves and Sieving Machines

- Filter Testing Machine FPV for Dispersion Properties of Polymers and Pigments

- Customizable XRD Sample Holders for Diverse Research Applications

- Customizable PTFE Wafer Carriers for Semiconductor and Lab Applications

People Also Ask

- What is the role of CR2016 coin cell components in Li2MnSiO4/C evaluation? Optimize Your Battery Research Results

- Why is an argon-filled glove box essential for Li-CuMH solid-state batteries? Ensure Component Stability

- What is carbon cloth made of? Discover the Versatile High-Performance Fabric

- Why are Al-doped LLZO samples subjected to post-treatment? Restoring Purity for Solid Electrolyte Performance

- Why is initial calcination at 600 °C necessary for Bi-doped membrane powders? Prevent Defects & Ensure Density

- How is a laboratory manual hydraulic press used in solid-state battery testing? Optimize Electrode Performance

- What role does an anion exchange membrane play in a PEC battery? Ensure Safe, High-Purity Hydrogen Production

- What is the meaning of roll press? A Critical Step for High-Performance Battery Manufacturing