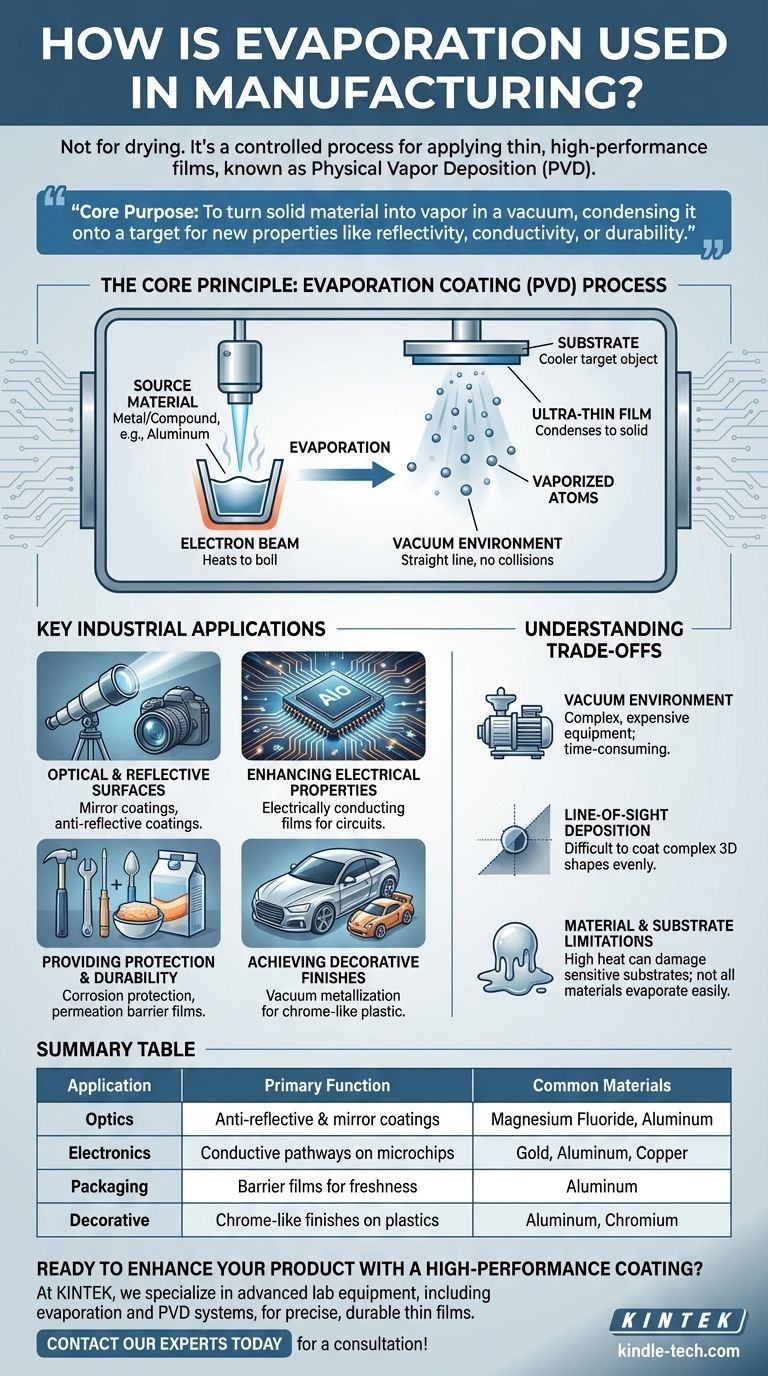

In manufacturing, evaporation is not about drying. It is a highly controlled process used to apply extremely thin, high-performance films of material onto a surface. This technique, known as physical vapor deposition (PVD), is essential for creating products ranging from precision optical lenses and microchips to the metallic lining inside a bag of potato chips.

The core purpose of industrial evaporation is to turn a solid material into a vapor within a vacuum, allowing it to condense onto a target object as a perfectly uniform and pure coating, thereby granting that object new properties like reflectivity, conductivity, or durability.

The Core Principle: How Evaporation Coating Works

Evaporation is a cornerstone of a manufacturing category called Physical Vapor Deposition (PVD). The fundamental concept is elegant and precise, regardless of the specific equipment used.

The Source Material

First, a source material—such as a metal like aluminum or a compound like magnesium fluoride—is placed inside a high-vacuum chamber.

The Evaporation Process

This source material is then heated until it boils and evaporates, turning directly into a gaseous vapor. This can be done using several methods, with a common one being an electron beam, which uses a focused beam of high-energy electrons to heat the material.

The Deposition Phase

Because this occurs in a vacuum, the vaporized atoms travel in a straight line without colliding with air molecules or contaminants. They eventually strike a cooler target object (called a substrate), where they condense and form a solid, ultra-thin film.

Key Industrial Applications

This ability to apply pure, precisely controlled layers enables critical functionalities across numerous high-tech and everyday products.

Creating Optical and Reflective Surfaces

Evaporation is fundamental for manufacturing high-performance optics. By depositing microscopically thin layers, engineers can create mirror coatings for telescopes or anti-reflective coatings for camera lenses and eyeglasses.

Enhancing Electrical Properties

In the electronics industry, evaporation is used to lay down electrically conducting films. This is how the intricate metallic pathways on microchips and other semiconductor devices are often created.

Providing Protection and Durability

A thin, evaporated film can serve as a powerful shield. This includes corrosion-protective coatings on tools and components or permeation barrier films on flexible food packaging to keep air and moisture out, preserving freshness.

Achieving Decorative Finishes

The process is also widely used for aesthetics. Often called vacuum metallization, it's how plastic parts on cars or toys are given a shiny, chrome-like finish without the weight or expense of actual metal.

Understanding the Trade-offs

While powerful, the evaporation process has specific constraints that make it suitable for some applications but not others.

Requirement for a Vacuum Environment

Creating and maintaining a high vacuum requires complex, expensive equipment and adds significant time to the manufacturing cycle. This makes the process less suitable for low-cost, high-volume items that do not require high-purity coatings.

Line-of-Sight Deposition

The evaporated atoms travel in a straight line from the source to the substrate. This makes it difficult to evenly coat objects with complex, three-dimensional shapes, as surfaces not in the direct "line of sight" will receive little to no coating.

Material and Substrate Limitations

The process involves very high temperatures, which can damage or deform heat-sensitive substrates. Furthermore, not all materials can be easily evaporated; some may decompose rather than turn into a clean vapor.

Making the Right Choice for Your Goal

The decision to use evaporation coating depends entirely on the desired properties of the final product.

- If your primary focus is optical performance: Evaporation is the premier choice for creating the highly precise, multi-layered films required for lenses, filters, and mirrors.

- If your primary focus is electronics manufacturing: This process is a fundamental tool for depositing the conductive and insulating layers that form modern circuits.

- If your primary focus is surface protection or aesthetics: Vacuum metallization provides a thin, consistent, and durable film for everything from food packaging to decorative automotive parts.

Ultimately, industrial evaporation is a foundational technology for adding value and function to a surface, one atom at a time.

Summary Table:

| Application | Primary Function | Common Materials |

|---|---|---|

| Optics | Anti-reflective & mirror coatings | Magnesium Fluoride, Aluminum |

| Electronics | Conductive pathways on microchips | Gold, Aluminum, Copper |

| Packaging | Barrier films for freshness | Aluminum |

| Decorative | Chrome-like finishes on plastics | Aluminum, Chromium |

Ready to enhance your product with a high-performance coating?

At KINTEK, we specialize in advanced lab equipment, including evaporation and PVD systems, to help you develop and apply precise, durable thin films. Whether you're creating advanced optics, sophisticated electronics, or protective packaging, our solutions are designed for accuracy and reliability.

Let's discuss your project and how our expertise can benefit your manufacturing process.

Contact our experts today for a consultation!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is the difference between PECVD and sputter? Choose the Right Thin-Film Deposition Method

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What is the plasma CVD process? Achieve Low-Temperature Thin Film Deposition