As a general rule, an autoclave's heat-up phase typically takes between 15 and 45 minutes to reach the standard sterilization temperature of 121°C. However, this is only one part of the total process. The complete cycle time is significantly longer and depends heavily on the specific autoclave, its starting temperature, and the size and type of the load being sterilized.

The critical insight is that focusing only on the heat-up time is misleading. True sterilization efficacy and efficient workflow planning require understanding the entire three-part autoclave cycle: heat-up, exposure, and cool-down.

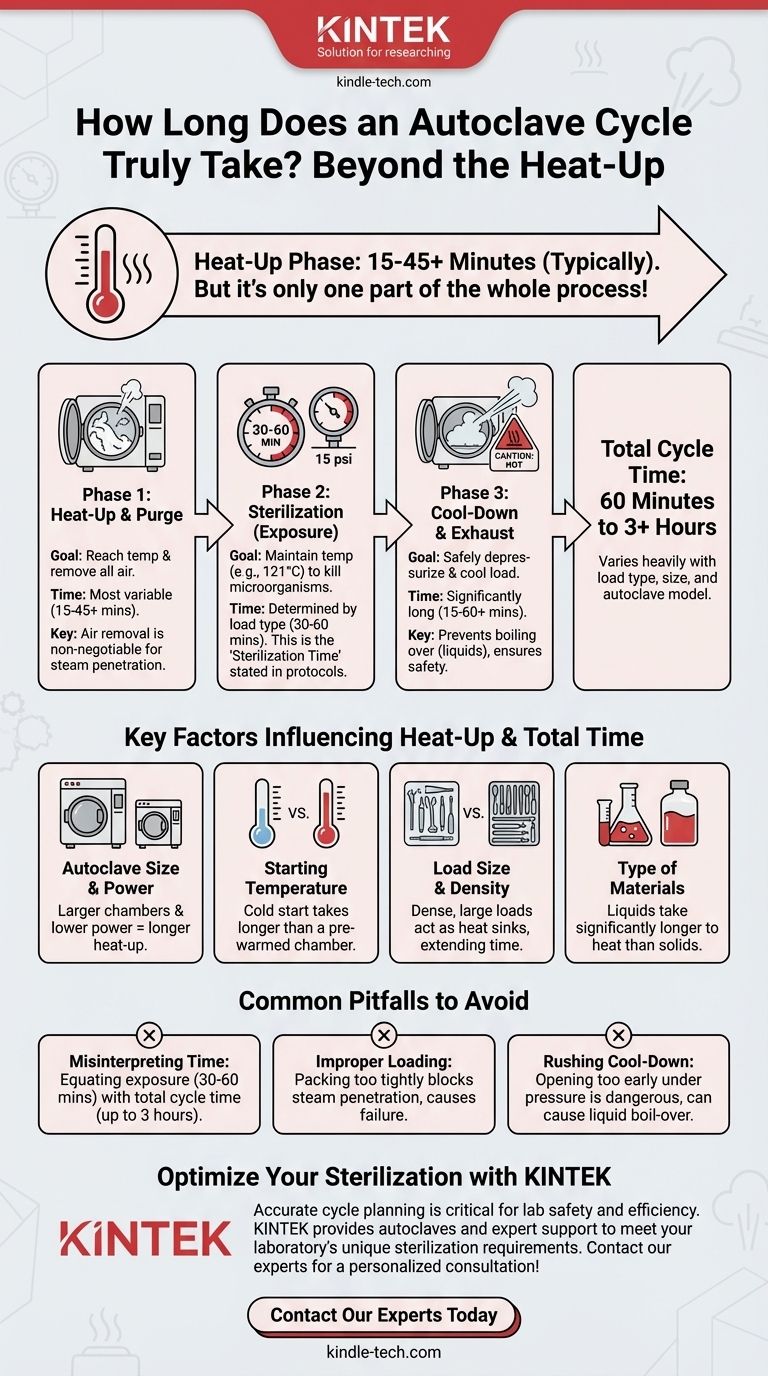

The Three Phases of a Complete Autoclave Cycle

Many people mistakenly believe the sterilization time stated in a protocol (e.g., 30 minutes at 121°C) is the total time required. In reality, this "exposure" period is just the middle phase of a much longer process.

Phase 1: The Heat-Up and Purge Phase

This initial phase involves heating the chamber and, crucially, purging all air. Steam is injected to displace the colder, denser air.

This step is non-negotiable because trapped air acts as an insulator, preventing the saturated steam from making direct contact with the items and leading to failed sterilization. The time this takes is the most variable part of the cycle.

Phase 2: The Sterilization (Exposure) Phase

Once the chamber reaches the target temperature (e.g., 121°C) and pressure (e.g., 15 psi), the timer for the sterilization phase begins.

The duration, often between 30 to 60 minutes, is determined by the nature of the load. Densely packed instruments or large volumes of liquid require longer exposure times to ensure the steam fully penetrates and kills all microorganisms.

Phase 3: The Exhaust and Cool-Down Phase

After the exposure time is complete, the steam is vented from the chamber. The pressure slowly returns to ambient levels.

This phase can be surprisingly long, especially for liquid loads, where a slow, controlled depressurization is necessary to prevent boiling over. Cooling the load to a safe handling temperature can add significant time to the overall cycle.

Key Factors Influencing Heat-up Time

There is no single answer for heat-up duration because it is a function of several variables.

Autoclave Size and Power

Larger autoclave chambers naturally take longer to heat than smaller, benchtop models. The power rating of the heating elements is also a primary factor.

Starting Temperature

A "cold start" at the beginning of the day will always take longer than a "warm start" where the autoclave has been recently run and the chamber jacket is already hot.

Load Size and Density

A large, dense load of surgical instruments acts as a significant heat sink. It will take much longer for the entire mass to reach the target temperature compared to a small, loosely packed load.

Type of Materials

Sterilizing liquids takes considerably longer than sterilizing solid, non-porous items like glassware. The liquid itself must be heated to the target temperature, which is a much slower process than heating surfaces with steam.

Common Pitfalls and Misconceptions

Understanding the variables helps avoid common errors that compromise sterilization and waste time.

Misinterpreting the "Sterilization Time"

The most common error is equating the 30-60 minute exposure time with the total cycle time. A complete cycle, from start to finish, for a significant load often takes 90 minutes to two hours or more.

Improper Loading

Packing items too tightly prevents effective air removal and steam penetration. This not only extends the heat-up time but is a primary cause of failed sterilization cycles. Always leave space between items.

Rushing the Cool-Down

Opening the autoclave door while the contents are still under pressure is extremely dangerous. For liquids, it can cause them to boil violently and burst their containers. Always allow the pressure to return to zero before opening the door.

Estimating Your Total Cycle Time

Instead of focusing on one phase, you must plan for the entire process.

- If your primary focus is sterilizing small, solid instruments: You can likely expect a total cycle time of 60-90 minutes, with the heat-up phase being around 20-30 minutes of that.

- If your primary focus is sterilizing large volumes of liquid: The total cycle time will be much longer, potentially 2-3 hours, as both the heat-up and cool-down phases are significantly extended.

- If your primary focus is ensuring guaranteed sterility: Always follow the manufacturer's validated cycles for your specific load type and use chemical and biological indicators to confirm that proper sterilization conditions were achieved.

Ultimately, understanding the entire autoclave cycle—not just the heat-up time—is the key to ensuring safe, effective sterilization and efficient laboratory workflow.

Summary Table:

| Phase | Typical Duration | Key Purpose |

|---|---|---|

| Heat-up & Purge | 15 - 45+ minutes | Heat chamber and remove all air for steam penetration. |

| Sterilization (Exposure) | 30 - 60 minutes | Maintain temperature to kill all microorganisms. |

| Cool-down & Exhaust | 15 - 60+ minutes | Safely depressurize and cool load for handling. |

| Total Cycle Time | 60 minutes - 3+ hours | Varies significantly with load type and autoclave size. |

Optimize Your Lab's Sterilization Process with KINTEK

Accurate cycle planning is critical for lab safety and efficiency. Whether you're sterilizing instruments, glassware, or liquids, using the right autoclave for your specific needs ensures reliable results and protects your workflow.

KINTEK specializes in lab equipment and consumables, providing autoclaves and expert support to meet your laboratory's unique sterilization requirements.

Let us help you select the perfect autoclave to guarantee sterility and streamline your processes. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

People Also Ask

- What is the life expectancy of an autoclave machine? Maximize Your Investment with Proper Care

- What critical environmental conditions does a laboratory autoclave provide for evaluating wear resistance? - KINTEK

- How do you use an autoclave in a microbiology lab? Master Sterilization for Lab Safety & Accuracy

- What is the necessity of using an autoclave for pre-treating culture media? Ensure Accurate Ag2O/TiO2 Testing

- What role do laboratory autoclaves play in pectin extraction? Optimize Prebiotic Yield from Citrus and Apple Biomass