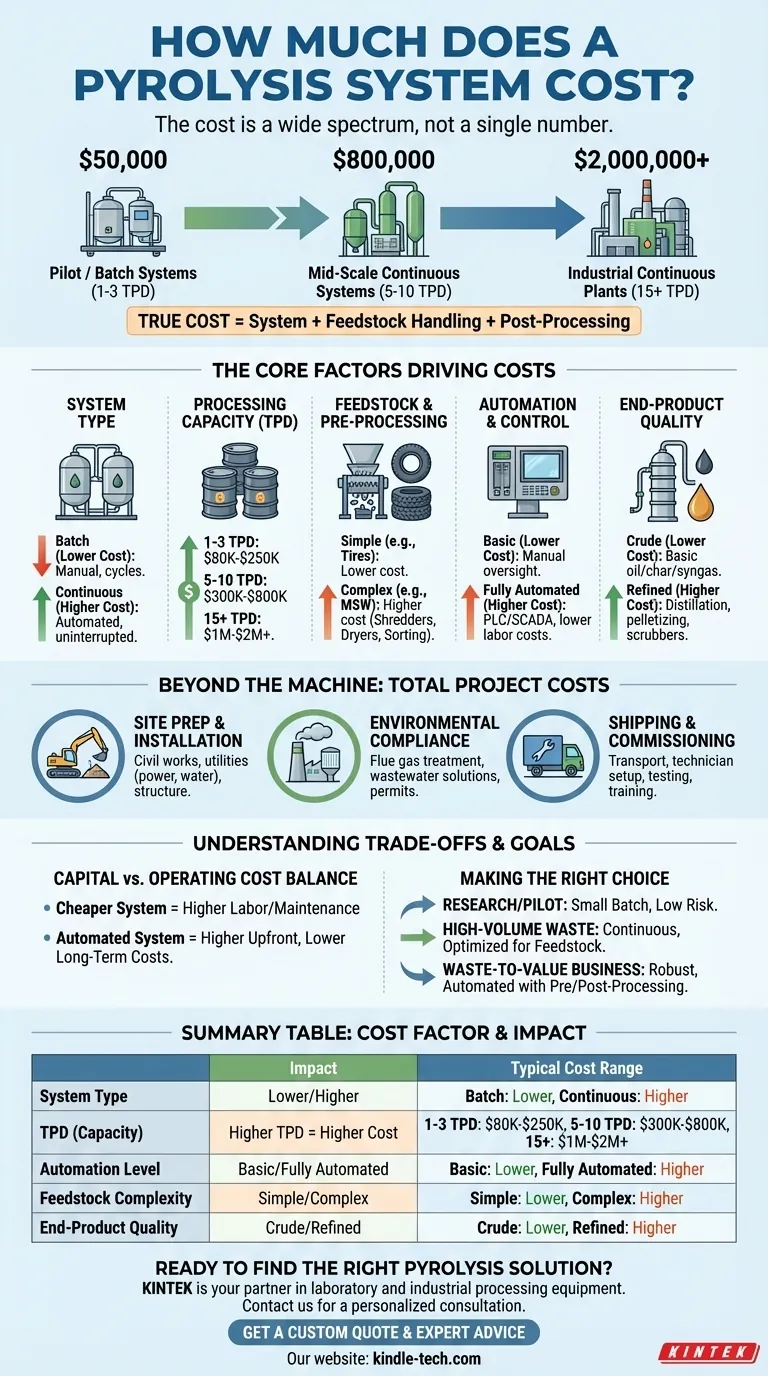

The cost of a pyrolysis system is not a single number but a wide spectrum dictated by its scale, technology, and purpose. For a professional context, you should expect a range from approximately $50,000 for small, skid-mounted batch systems suitable for pilot projects, to well over $2,000,000 for fully automated, continuous industrial plants capable of processing significant daily tonnage.

The initial purchase price of the pyrolysis reactor is only the starting point. A true cost assessment must account for system capacity, feedstock handling requirements, and the level of post-processing needed to create marketable end-products.

The Core Factors Driving Pyrolysis System Costs

Understanding the price of a pyrolysis system requires looking beyond the reactor itself. The final cost is a function of several interdependent engineering and operational decisions.

System Type: Batch vs. Continuous

A batch system is the most affordable entry point. The feedstock is loaded, the process runs, and then the products are removed before the next cycle begins. This is ideal for smaller volumes or research.

A continuous system is designed for industrial-scale operations. It features automated feeding and discharge mechanisms, allowing for uninterrupted processing. This complexity and scale significantly increase the capital cost but lower the per-ton operating cost.

Processing Capacity (Throughput)

This is the most direct cost driver. The larger the reactor and the more tons per day (TPD) it can process, the higher the price.

- 1-3 TPD Systems: Often fall in the $80,000 to $250,000 range.

- 5-10 TPD Systems: Typically cost between $300,000 and $800,000.

- 15+ TPD Systems: These are large industrial installations that frequently exceed $1,000,000 to $2,000,000+, depending on complexity.

Feedstock and Pre-processing

The type of material you intend to process heavily influences the required ancillary equipment, which is often a separate cost.

A system designed for a uniform feedstock like tires is simpler than one intended for mixed plastics or municipal solid waste (MSW). These more complex feedstocks require expensive shredders, dryers, and sorting systems before they can enter the reactor.

Automation and Control

The level of automation is a major cost variable. A basic system may require significant manual oversight for loading, monitoring, and unloading.

A fully automated plant uses Programmable Logic Controllers (PLCs) and SCADA systems to manage the entire process. This increases the upfront investment but drastically reduces long-term labor costs and improves process consistency.

Quality of End Products

A basic system will produce a crude pyrolysis oil, a carbon-rich char, and syngas. If you need to upgrade these products to sell them at a higher value, you must invest in post-processing equipment.

This can include distillation columns to refine the oil, grinding and pelletizing equipment for the char, and gas scrubbers or generators to utilize the syngas. Each addition adds significant cost.

Beyond the Machine: Understanding Total Project Costs

The price quoted by a manufacturer is rarely the final project cost. A comprehensive budget must include several other critical expenses.

Site Preparation and Installation

This includes the cost of a concrete foundation, a structure to house the equipment, and bringing necessary utilities (power, water) to the site. These civil engineering costs can be substantial.

Environmental Compliance

Meeting local air and water quality regulations is non-negotiable. This often requires sophisticated and expensive flue gas treatment systems and wastewater management solutions, which must be factored into the total cost.

Shipping, Commissioning, and Training

The logistics of transporting heavy industrial equipment, along with the cost of having technicians on-site for installation, testing (commissioning), and training your operational staff, represent a significant final expense.

Understanding the Trade-offs

Making an informed investment requires balancing upfront capital costs with long-term operational viability.

The Capital vs. Operating Cost Balance

A cheaper, less-automated system may seem appealing initially. However, it will likely demand higher ongoing costs for labor, maintenance, and potentially suffer from lower efficiency, impacting your profitability over the life of the project.

The Risk of Low-Cost Systems

Be cautious of unusually low-priced systems. These often cut corners on material quality (e.g., the type of steel used in the reactor), safety features, and environmental controls. This can lead to premature failure, safety hazards, and an inability to secure operating permits.

Efficiency and Energy Integration

A key feature of a well-designed system is its ability to use its own product—the non-condensable syngas—to power the reactor heaters. Systems lacking this feature will have permanently higher operational costs due to their reliance on external fuel sources.

Making the Right Choice for Your Goal

To determine the right investment, you must first clarify your primary objective.

- If your primary focus is research or a small-scale proof-of-concept: A small, skid-mounted batch system offers the lowest capital risk to validate your process.

- If your primary focus is processing a consistent, high-volume waste stream (e.g., tires or specific plastics): Invest in a continuous system optimized for that feedstock to maximize throughput and operational efficiency.

- If your primary focus is creating a versatile waste-to-value business: Budget for a robust, automated system with significant capital allocated for both pre-processing and post-processing equipment.

Focusing on these core drivers will allow you to build a comprehensive business case and select a system that truly aligns with your operational and financial goals.

Summary Table:

| Cost Factor | Impact on Price | Typical Cost Range |

|---|---|---|

| System Type | Batch vs. Continuous | Batch: Lower cost Continuous: Higher cost |

| Processing Capacity | Tons Per Day (TPD) | 1-3 TPD: $80K-$250K 5-10 TPD: $300K-$800K 15+ TPD: $1M-$2M+ |

| Automation Level | Manual vs. PLC/SCADA | Basic: Lower cost Fully Automated: Higher cost |

| Feedstock Complexity | Pre-processing Needs | Simple (e.g., tires): Lower cost Complex (e.g., MSW): Higher cost |

| End-Product Quality | Post-processing Equipment | Crude oil/char: Lower cost Refined products: Higher cost |

Ready to find the right pyrolysis solution for your project?

Navigating the wide range of pyrolysis system costs and configurations can be complex. The right choice balances your initial investment with long-term operational efficiency and profitability.

KINTEK is your partner in laboratory and industrial processing equipment. We can help you analyze your specific needs—whether for research, proof-of-concept, or full-scale waste-to-value operations—to identify a system that fits your budget and technical requirements.

Contact us today to discuss your project goals and receive a personalized consultation. Let our expertise guide you to a successful investment.

Get a Custom Quote & Expert Advice

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

People Also Ask

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas