In short, no. A colloid mill is not a homogenizer, although both are used to reduce particle size and create stable mixtures. They achieve this through fundamentally different mechanical principles, resulting in distinct outputs and ideal applications. A colloid mill primarily uses intense mechanical shear, while a classic high-pressure homogenizer relies on forces like cavitation and turbulence generated by immense pressure.

The core confusion arises because both machines can "homogenize" a product in the general sense of making it uniform. However, in process engineering, the distinction is critical: a colloid mill is a high-shear rotor-stator mixer, whereas a high-pressure homogenizer is a specialized device that uses a completely different physical phenomenon to achieve much finer results.

The Core Distinction: Shear vs. Pressure

To select the right equipment, you must first understand the fundamental difference in how they work. The method of particle reduction directly impacts the final product's characteristics.

How a Colloid Mill Works: The Rotor-Stator Principle

A colloid mill operates on the principle of a rotor-stator mechanism.

A cone-shaped rotor spins at a very high speed (thousands of RPM) in extremely close proximity to a stationary stator. The gap between them is precisely controlled and can be adjusted.

Fluid is fed into this tiny gap, where it is subjected to intense mechanical shear, hydraulic pressure, and friction. This action is like a microscopic set of scissors, physically tearing and grinding particles apart.

How a High-Pressure Homogenizer Works: The Power of Cavitation

A high-pressure homogenizer (HPH) uses a completely different set of forces.

It employs a powerful pump to force a liquid stream at extremely high pressure (up to tens of thousands of PSI) through a very small, adjustable valve.

As the fluid exits the valve, its velocity increases dramatically and its pressure plummets. This sudden pressure drop causes cavitation—the formation and instantaneous collapse of microscopic vapor bubbles. The violent collapse of these bubbles creates powerful shockwaves that shatter particles with extreme efficiency.

Comparing Key Performance Outcomes

The difference in mechanism leads to significant differences in performance, which dictates the ideal application for each machine.

Final Particle Size

This is the most critical differentiator. A colloid mill is excellent for reducing particles down to the low-micron range, typically between 2 and 5 microns.

A high-pressure homogenizer is designed for much finer dispersions, consistently achieving sub-micron particle sizes, often well into the nanometer scale.

Emulsion Stability

Because a high-pressure homogenizer produces significantly smaller and more uniform particles, it creates far more stable emulsions. These emulsions resist separation for much longer periods.

Emulsions from a colloid mill are effective for many applications but may be less stable over the long term compared to those processed through an HPH.

Viscosity Handling

Colloid mills excel at processing high-viscosity materials. Their robust mechanical shearing action is ideal for creating thick pastes, gels, ointments, and sauces.

High-pressure homogenizers are generally limited to lower-viscosity liquids that can be efficiently pumped through the small homogenizing valve.

Understanding the Trade-offs

Neither machine is universally better; they are specialized tools for different jobs. Choosing the wrong one can lead to process inefficiencies and poor product quality.

The Colloid Mill: Simplicity and Versatility

A colloid mill's primary advantages are its lower capital cost, simpler mechanical design, and easier maintenance.

It is a versatile workhorse for applications where sub-micron particles are not required, especially when dealing with thick or pasty products. Its limitation is the ceiling on particle size reduction.

The High-Pressure Homogenizer: Precision and Power

An HPH offers unparalleled particle size reduction and creates the most stable products possible. This is essential in industries like pharmaceuticals, dairy (for milk), and high-performance chemicals.

The trade-offs are a significantly higher initial investment, greater complexity, higher energy consumption, and an inability to handle very viscous or abrasive materials without pre-processing.

Making the Right Choice for Your Process

Your choice depends entirely on your target particle size, required stability, and product viscosity.

- If your primary focus is creating pastes, thick sauces, or processing high-viscosity materials: A colloid mill is your most effective and economical choice.

- If your primary focus is achieving maximum emulsion stability and the smallest possible particle size (sub-micron): A high-pressure homogenizer is the necessary tool for the job.

- If your primary focus is general-purpose dispersion with moderate particle size reduction at a lower capital cost: A colloid mill offers greater operational versatility and simplicity.

Understanding the distinction between mechanical shear and pressure-induced cavitation empowers you to select the precise tool for your desired outcome.

Summary Table:

| Feature | Colloid Mill | High-Pressure Homogenizer |

|---|---|---|

| Primary Mechanism | Mechanical Shear (Rotor-Stator) | Cavitation & Turbulence (High Pressure) |

| Typical Particle Size | 2 - 5 microns | Sub-micron (Nanometer scale) |

| Ideal Viscosity | High (Pastes, Gels) | Low to Medium |

| Best For | Thick sauces, ointments, cost-effective dispersion | Maximum emulsion stability, nano-emulsions |

Still unsure which equipment is right for your lab's specific needs?

KINTEK specializes in lab equipment and consumables, helping laboratories like yours select the perfect tools for optimal results. Our experts can guide you through the pros and cons of colloid mills, homogenizers, and other dispersion equipment to ensure you achieve your target particle size and product stability.

Contact us today for a personalized consultation and let us help you enhance your process efficiency. Get in touch via our contact form!

Related Products

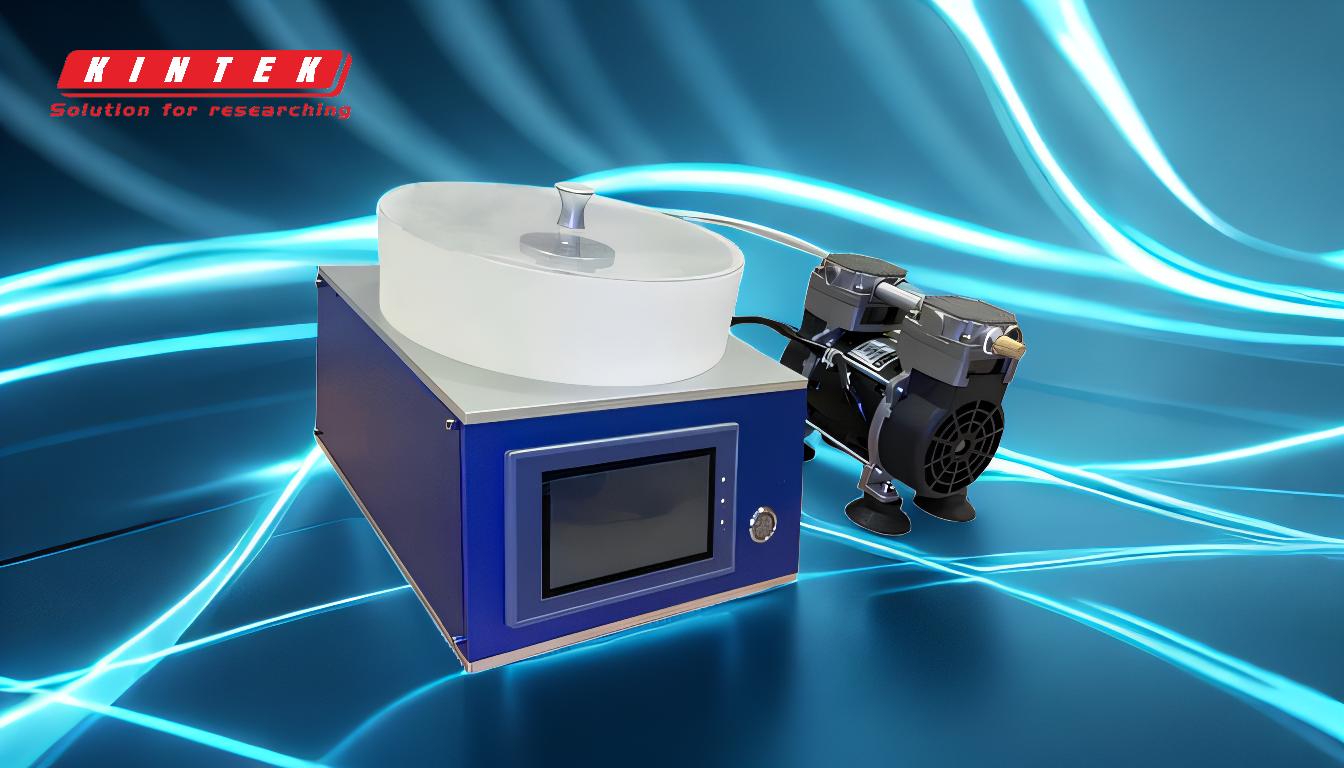

- Laboratory Homogenizer Mixer Benchtop Homogenizer with 8 Inch PP Chamber

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Laboratory Test Sieves and Sieving Machines

- Laboratory Single Horizontal Jar Mill

- High Energy Vibratory Laboratory Ball Mill Double Tank Type

People Also Ask

- What is the capacity of a colloid mill? A Guide to True Throughput vs. Rated Specs

- What is the difference between mixer and disperser? Choose the Right Tool for Your Process

- What is the use of grinding in laboratory? Unlock Accurate & Homogeneous Sample Analysis

- What are the advantages of a colloid mill? Achieve Superior Particle Size Reduction and Stable Emulsions

- What is the particle size of a colloid mill? Achieve 1-5 Micron Emulsions for Superior Stability