No, a pre-press mold is not strictly necessary to make rosin, but omitting one is a common source of inconsistent results and lower yields. Using a mold compacts your starting material into a dense, uniform puck, which is critical for ensuring an even flow of rosin during extraction and getting the most out of your material.

The core function of a pre-press mold is to eliminate variables. It transforms loose, inconsistent cannabis material into a standardized puck, ensuring even pressure distribution and preventing common issues like filter bag blowouts and trapped oil.

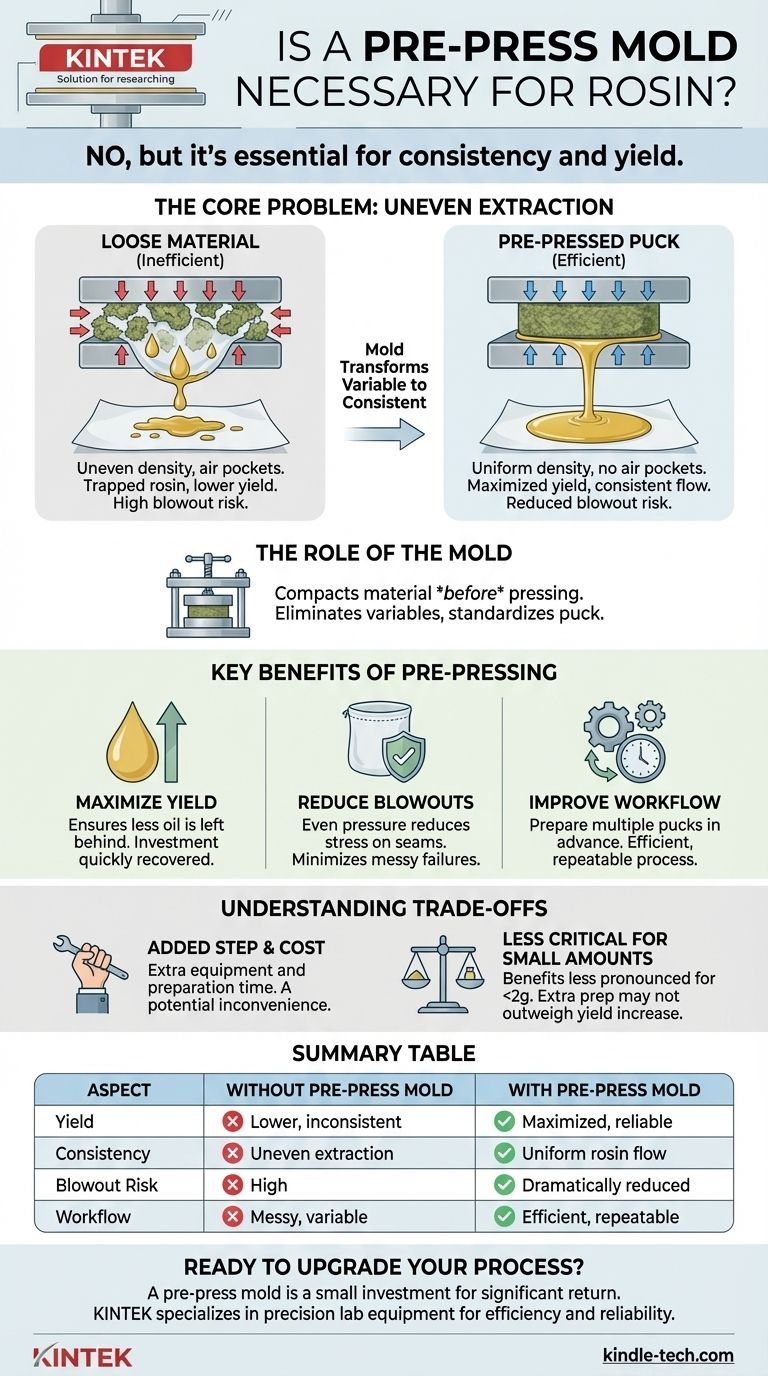

The Core Problem: Uneven Extraction

To understand the value of a pre-press mold, you first need to understand the primary challenge of pressing loose material directly inside a filter bag.

Why Loose Material is Inefficient

When you press loose flower or hash, the material has uneven density and is filled with tiny air pockets.

Under pressure, the rosin press plates will not apply force evenly. The pressure will find the path of least resistance, often creating channels that leave other parts of the material under-extracted.

This inefficiency means valuable rosin gets trapped inside the filter bag, significantly reducing your potential yield.

The Role of the Mold

A pre-press mold solves this problem by compacting your material before it goes into the press.

By applying pressure (often with a clamp or your body weight), the mold forces out air pockets and creates a puck of uniform shape and density.

Consistent Density, Consistent Results

This dense, uniform puck allows the heat and pressure from your rosin plates to be distributed evenly across the entire surface.

The result is a consistent, predictable flow of rosin from all sides of the puck, maximizing the amount of oil that escapes the filter bag and ends up on your parchment paper.

Key Benefits of Pre-Pressing

Moving from pressing loose material to using a pre-press mold offers three distinct advantages that directly impact your final product and workflow.

Maximizing Your Yield

This is the most significant benefit. An even extraction ensures that less oil is left behind. The small investment in a mold is often quickly recovered through the value of the additional rosin you collect over time.

Reducing Filter Bag Blowouts

Blowouts are a common frustration when pressing rosin. They occur when uneven pressure causes a weak point in the filter bag to tear.

A properly sized, pre-pressed puck fits snugly and evenly within the bag, dramatically reducing the stress on the mesh seams and minimizing the risk of a costly and messy blowout.

Improving Your Workflow

Pre-pressing allows you to prepare multiple pucks in advance. This creates a much more efficient and repeatable process, especially if you are pressing larger quantities.

Understanding the Trade-offs

While highly recommended, a pre-press mold isn't without its considerations. It's important to view it as a process improvement tool rather than an absolute requirement for every situation.

The Added Step and Cost

The most obvious downside is that it adds another piece of equipment to your setup and an extra step to your preparation process. For those seeking the absolute simplest method, this can feel like an inconvenience.

When It Might Be Less Critical

If you are only pressing very small amounts (e.g., one or two grams at a time), the benefits of a perfectly uniform puck may be less pronounced. While still helpful, the potential yield increase might not feel as significant compared to the extra prep time.

Making the Right Choice for Your Goal

Ultimately, the decision to use a pre-press mold depends on what you want to achieve with your rosin extraction.

- If your primary focus is maximizing yield and consistency: A pre-press mold is an essential tool that pays for itself by preventing waste and ensuring repeatable, high-quality results.

- If your primary focus is simplicity for occasional, personal presses: You can proceed without one, but accept that you will likely face more inconsistent outcomes and a higher risk of blowouts.

Using a pre-press mold is a small investment in transforming your extraction process from a variable art into a repeatable science.

Summary Table:

| Aspect | Without Pre-Press Mold | With Pre-Press Mold |

|---|---|---|

| Yield | Lower, inconsistent | Maximized, reliable |

| Consistency | Uneven extraction | Uniform rosin flow |

| Blowout Risk | High | Dramatically reduced |

| Workflow | Messy, variable | Efficient, repeatable |

Ready to upgrade your rosin extraction process? A pre-press mold is a small investment that delivers a significant return in yield and consistency. At KINTEK, we specialize in precision lab equipment designed for efficiency and reliability. Whether you're a hobbyist or scaling up production, our tools help you achieve professional results every time. Contact us today to find the perfect pre-press solution for your needs!

Visual Guide

Related Products

- Polygon Press Mold for Lab

- Special Shape Press Mold for Lab

- Assemble Lab Cylindrical Press Mold

- Round Bidirectional Press Mold for Lab

- Ball Press Mold for Lab

People Also Ask

- What is the press mould method? A Guide to Consistent, Detailed Ceramic Forms

- What are the advantages of mould? Harnessing Nature's Microscopic Factories

- How to use a press mold? Master the Art of Creating Consistent Ceramic Forms

- What is a press mold used for? Achieve Repeatable Precision and Efficiency

- Is it fitting the mould or mold? A Guide to Correct Spelling by Region