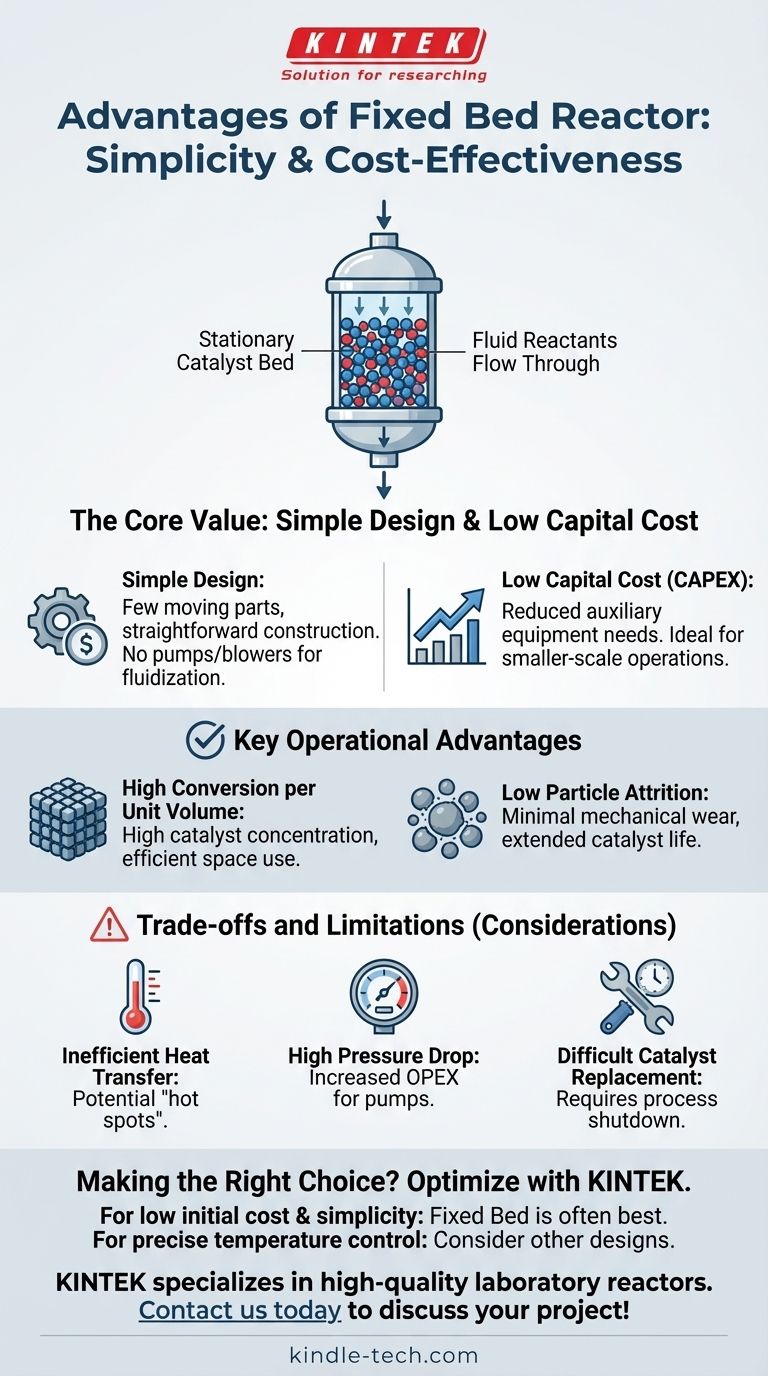

The primary advantages of a fixed bed reactor are its simple design, lower capital cost, and operational straightforwardness. Because the solid particles (catalyst or reactant) remain stationary, the system avoids the complexity and cost associated with fluidizing pumps, blowers, and downstream particle separation equipment required by other reactor types.

The core value of a fixed bed reactor lies in its simplicity and cost-effectiveness. It is an excellent choice for processes where precise temperature control is not the primary concern and where the catalyst has a long operational life.

The Defining Principle: Simplicity in Design

A fixed bed reactor's advantages stem directly from its fundamental structure—a vessel packed with solid particles through which fluid reactants pass.

A Static, Uncomplicated Structure

The design consists of a stationary bed of solid particles, typically a catalyst, packed within a cylindrical vessel. Reactants flow through the empty spaces between these particles, where the chemical reaction takes place.

This static arrangement is mechanically simple, involving few or no moving parts within the reactor itself.

Reduced Auxiliary Equipment

Unlike fluidized bed reactors, a fixed bed design does not require a high-velocity fluid to suspend the particles. This eliminates the need for powerful blowers or pumps dedicated to fluidization, reducing both initial investment and energy consumption.

Key Operational Advantages

The simple design translates into several tangible benefits during operation.

Cost-Effectiveness

The straightforward construction and minimal auxiliary equipment make fixed bed reactors one of the least expensive reactor types to build and install. This lower capital expenditure (CAPEX) is a major advantage, especially for smaller-scale operations.

High Conversion per Unit Volume

Fixed bed reactors can achieve a high concentration of catalyst within the reactor volume. This allows for a high rate of conversion for a given reactor size, making them very efficient in terms of space.

Low Particle Attrition

Because the catalyst particles are stationary and not colliding with each other, mechanical wear and breakdown (attrition) are minimal. This extends the life of the catalyst and prevents the formation of fine dust that could contaminate the product stream.

Understanding the Trade-offs and Limitations

To make an informed decision, you must weigh the advantages against the inherent limitations of the design.

Inefficient Heat Transfer

This is the most significant drawback. Heat does not distribute evenly throughout the static bed, leading to temperature gradients. For highly exothermic reactions, this can create dangerous "hot spots" that damage the catalyst and produce unwanted byproducts.

Potential for High-Pressure Drop

Forcing a fluid through a tightly packed bed of particles creates resistance, resulting in a significant pressure drop from the inlet to the outlet. Overcoming this pressure drop requires more powerful pumps, which increases operating expenditure (OPEX).

Difficulty with Catalyst Replacement

When the catalyst loses its effectiveness, the entire process must be shut down to unload the old particles and load the new ones. This downtime is a major disadvantage for processes that require frequent catalyst regeneration or replacement.

Making the Right Choice for Your Process

The suitability of a fixed bed reactor depends entirely on the specific goals and constraints of your chemical process.

- If your primary focus is low initial cost and operational simplicity: A fixed bed reactor is often the best choice, particularly for reactions with moderate heat effects.

- If your primary focus is precise temperature control for a highly exothermic reaction: You should consider other designs like a fluidized bed reactor or a shell-and-tube fixed bed reactor to manage heat more effectively.

- If your primary focus is continuous operation with catalysts that deactivate quickly: A fixed bed is likely unsuitable due to the downtime required for replacement; a moving bed or fluidized bed reactor would be a better fit.

Understanding these fundamental trade-offs empowers you to select the optimal reactor technology for your specific application.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Simple Design | Few moving parts, straightforward construction |

| Low Capital Cost (CAPEX) | Reduced equipment needs and installation costs |

| High Conversion per Unit Volume | Efficient use of reactor space |

| Low Catalyst Attrition | Stationary particles extend catalyst life |

Ready to optimize your chemical process with a reliable reactor?

At KINTEK, we specialize in providing high-quality laboratory equipment, including reactors tailored to your specific needs. Our fixed bed reactors are designed for cost-effective, high-efficiency performance, helping you maximize conversion rates and minimize operational costs.

Let our experts help you select the perfect reactor for your application. Contact us today to discuss your project and discover the KINTEK advantage!

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- Why are sealed laboratory reaction vessels necessary in the hydrothermal synthesis of zeolites? Ensure Purity and Yield

- What roles do autoclaves play in MFI zeolite synthesis? Master Hydrothermal Crystalline Growth

- Why are high-pressure autoclaves essential for preparing bio-based polyamide curing agents from dimeric acid?

- What is the function of a constant temperature hydrothermal reactor? Master Coal Fly Ash Activation

- What is the role of high-pressure reactors in the study of alloy oxidation? Essential Tools for Supercritical Research