The primary advantages of a packed bed reactor are its high conversion rate per unit volume, simplicity of construction, and efficiency in continuous operation. By filling a vessel with solid catalyst particles, it creates an enormous surface area for chemical reactions to occur as reactants flow through, making it a cornerstone of the chemical and process industries for gas-phase reactions.

A packed bed reactor's core strength lies in its ability to maximize the contact between reactants and a solid catalyst in a simple, continuous-flow design. This makes it exceptionally efficient for specific, large-scale industrial processes where high conversion is the primary goal.

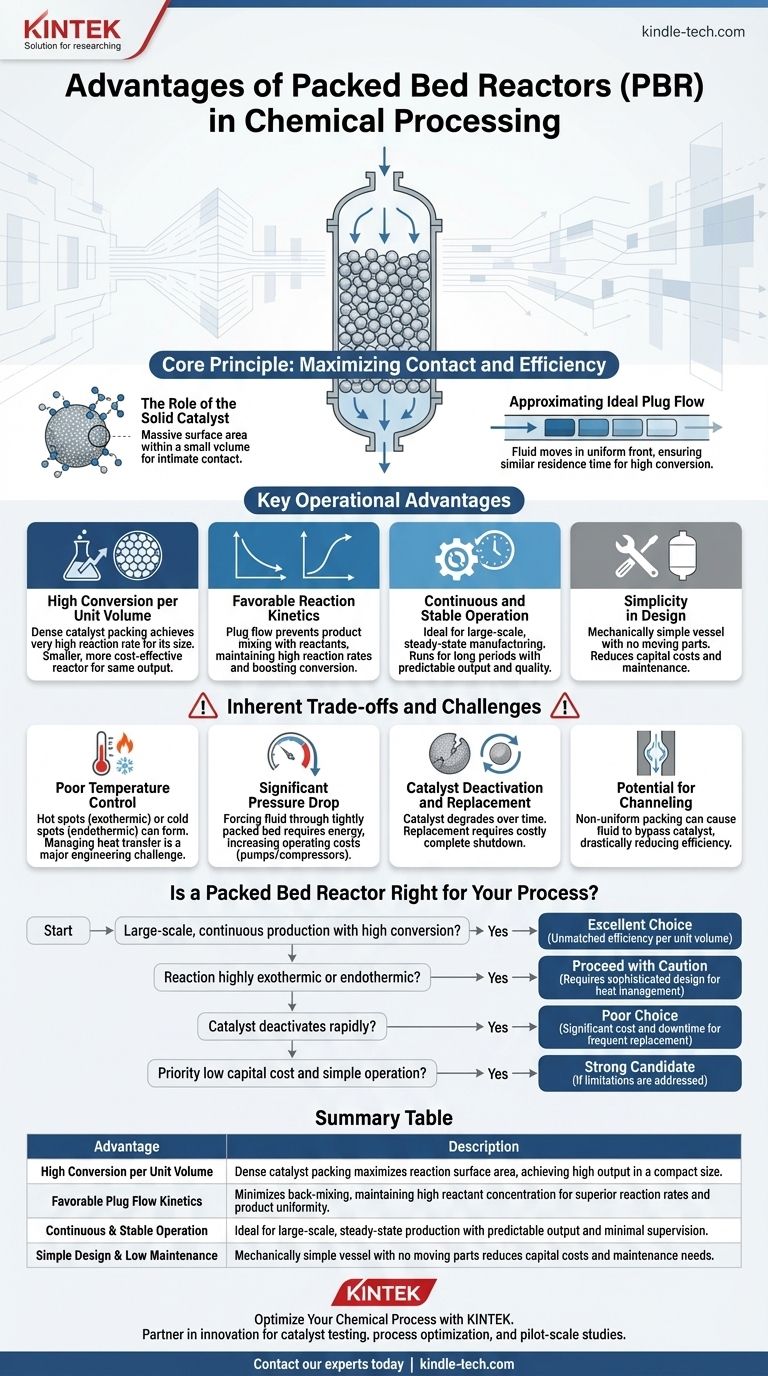

The Core Principle: Maximizing Contact and Efficiency

To understand the advantages of a packed bed reactor (PBR), you must first grasp its fundamental operating principle. It is designed to facilitate a reaction between a fluid (gas or liquid) and a solid catalyst.

The Role of the Solid Catalyst

A PBR is essentially a tube or vessel filled with catalyst pellets. This "packed bed" creates a massive surface area within a relatively small volume.

As the reactant fluid passes through the bed, it is forced into intimate contact with the catalyst surface, which is where the reaction takes place. This high catalyst-to-reactant ratio is a key driver of its efficiency.

Approximating Ideal Plug Flow

In an ideal PBR, the fluid moves through the reactor as a series of coherent "plugs" with minimal axial mixing. This is known as plug flow.

Think of a coffee percolator: water flows through the coffee grounds in a uniform front, extracting flavor as it goes, without the brewed coffee mixing back with the fresh water. This orderly progression ensures that all reactants have a similar residence time, leading to more uniform product quality and higher conversion.

Key Operational Advantages Explained

The PBR's fundamental design gives rise to several significant operational and economic benefits, making it the reactor of choice for many industrial applications.

High Conversion per Unit Volume

Because the reactor volume is densely packed with catalyst, the PBR achieves a very high rate of reaction for its size. This is a stark contrast to other reactor types, like a Continuous Stirred-Tank Reactor (CSTR), where the catalyst concentration is much lower.

This efficiency means you can build a smaller, less expensive reactor to achieve the same production output.

Favorable Reaction Kinetics

The plug flow behavior prevents the products from mixing with the incoming reactants. This is critical because in many reactions, the presence of product can slow down the reaction rate.

By keeping reactants concentrated at the inlet and allowing product concentration to build along the reactor's length, the PBR maintains a higher average reaction rate, further boosting conversion.

Continuous and Stable Operation

Packed bed reactors are designed for continuous operation, which is ideal for large-scale manufacturing. Once the process reaches a steady state, it can run for long periods with minimal supervision.

This stability leads to predictable output and product quality, which is essential for commodity chemical production, such as the synthesis of ammonia or sulfuric acid.

Simplicity in Design

The reactor itself is mechanically simple, often just a vessel with an inlet and an outlet, containing no moving parts. This simplicity reduces initial capital costs and minimizes maintenance requirements compared to more complex reactor systems.

Understanding the Inherent Trade-offs and Challenges

No reactor design is universally superior. The PBR's advantages come with significant trade-offs that must be carefully managed. Acknowledging these limitations is critical for making an informed decision.

Poor Temperature Control

This is arguably the most significant disadvantage of a PBR. For highly exothermic reactions (reactions that release heat), dangerous hot spots can form within the bed, potentially damaging the catalyst or causing runaway reactions.

Conversely, for endothermic reactions (reactions that absorb heat), "cold spots" can develop, effectively stopping the reaction in those zones. Managing heat transfer through a fixed bed is a major engineering challenge.

Significant Pressure Drop

Forcing a fluid, especially a gas, through a tightly packed bed of particles requires a significant amount of energy. This results in a pressure drop from the reactor inlet to the outlet.

This pressure drop increases operating costs due to the need for more powerful pumps or compressors.

Catalyst Deactivation and Replacement

The catalyst does not last forever. Over time, it can be poisoned, coked, or physically degraded.

In a PBR, replacing the catalyst requires a complete shutdown of the process. This downtime can be extremely costly for large-scale operations, unlike in a fluidized bed reactor where catalyst can be added and removed continuously.

Potential for Channeling

If the bed is not packed uniformly, the fluid can find a path of least resistance and "channel" through a specific section. This means a large portion of the expensive catalyst is bypassed, drastically reducing the reactor's overall efficiency.

Is a Packed Bed Reactor Right for Your Process?

Choosing a reactor is a matter of aligning its characteristics with your specific process goals.

- If your primary focus is large-scale, continuous production with high conversion: The PBR is an excellent choice, offering unmatched efficiency per unit volume for many gas-phase catalytic reactions.

- If your reaction is highly exothermic or endothermic: You must proceed with caution. A PBR may not be suitable unless a sophisticated design (e.g., a multi-tubular reactor) is used to manage the heat load effectively.

- If your catalyst deactivates rapidly: A PBR is likely a poor choice due to the significant cost and operational disruption associated with frequent shutdowns for catalyst replacement.

- If your priority is low capital cost and simple, stable operation: The mechanical simplicity and continuous nature of the PBR make it a very strong candidate, provided its limitations are addressed.

Ultimately, understanding these core principles and trade-offs empowers you to select the right tool for the job, ensuring an efficient and economical chemical process.

Summary Table:

| Advantage | Description |

|---|---|

| High Conversion per Unit Volume | Dense catalyst packing maximizes reaction surface area, achieving high output in a compact size. |

| Favorable Plug Flow Kinetics | Minimizes back-mixing, maintaining high reactant concentration for superior reaction rates and product uniformity. |

| Continuous & Stable Operation | Ideal for large-scale, steady-state production with predictable output and minimal supervision. |

| Simple Design & Low Maintenance | Mechanically simple vessel with no moving parts reduces capital costs and maintenance needs. |

Optimize Your Chemical Process with KINTEK

Are you looking to maximize conversion and efficiency in your large-scale production? The principles of a packed bed reactor—high surface area, plug flow, and continuous operation—are key to achieving these goals. At KINTEK, we specialize in providing robust laboratory equipment and consumables that help you model, test, and scale up these critical processes efficiently.

Our expertise supports industries in:

- Catalyst Testing & Development: Ensure optimal performance and longevity for your packed bed systems.

- Process Optimization: Fine-tune parameters like temperature and flow rates for maximum yield.

- Pilot-Scale Studies: Bridge the gap between lab research and full-scale industrial production safely.

Let KINTEK be your partner in innovation. Contact our experts today to discuss how our solutions can enhance your reactor design and process efficiency.

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- Why are sealed laboratory reaction vessels necessary in the hydrothermal synthesis of zeolites? Ensure Purity and Yield

- What is the purpose of using a high-temperature hydrothermal reactor? Enhance Iodine@Activated Carbon Cathode Synthesis

- What is the purpose of using high-purity argon gas in a high-pressure reactor? Ensure Precise Corrosion Test Data

- How does a high-pressure reactor demonstrate its value in accelerated aging? Predict Catalyst Durability Fast

- What roles do autoclaves play in MFI zeolite synthesis? Master Hydrothermal Crystalline Growth