The primary advantages of a wiped film evaporator are its ability to operate under deep vacuum and its extremely short residence time. This combination allows for the effective distillation of heat-sensitive, viscous, and high-boiling-point materials with minimal thermal degradation, making it a superior technology for purifying delicate, high-value compounds.

A wiped film evaporator solves a critical problem that conventional distillation cannot: how to purify materials that would be destroyed by prolonged exposure to high heat. It achieves this by using mechanical wipers to create an ultra-thin film of liquid, enabling near-instantaneous evaporation under vacuum.

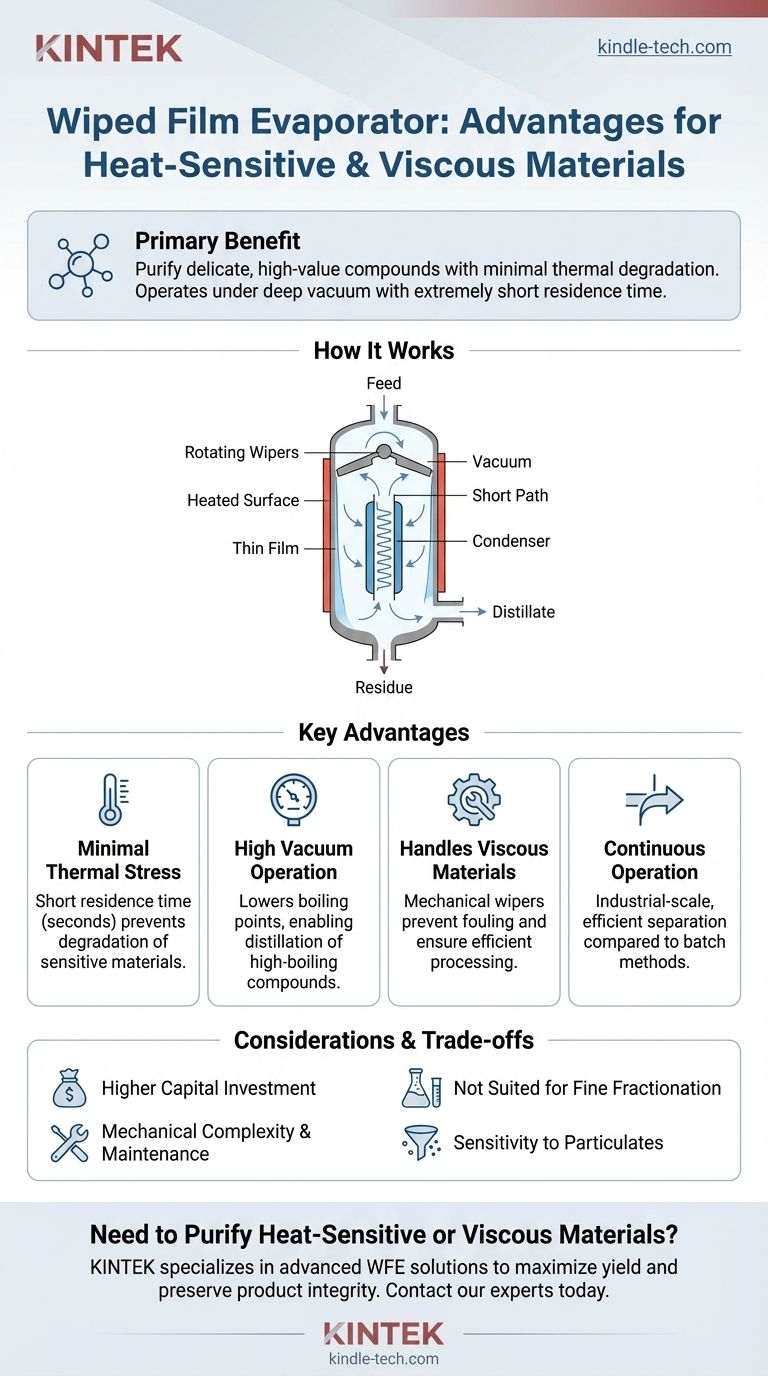

How Wiped Film Evaporation Works

To understand its advantages, it's essential to first grasp the core mechanism. Unlike a traditional boiling pot, a wiped film evaporator (WFE), also known as a thin-film evaporator, is an active and dynamic system.

The Core Principle: A Thin, Agitated Film

Feed liquid is introduced into a vertical, heated cylinder. A rotating assembly of wipers or rollers inside the cylinder spreads this liquid into a very thin, turbulent film against the hot inner surface.

This thin film maximizes the surface-area-to-volume ratio, resulting in exceptionally rapid and efficient heat transfer into the material.

The Role of High Vacuum

The entire system operates under a deep vacuum, which significantly lowers the boiling point of the compounds being separated.

Instead of boiling a compound at 300°C at atmospheric pressure, a WFE might allow it to evaporate at 150°C under vacuum. This is the key to preventing thermal decomposition.

The "Short Path" to Condensation

In a specific WFE configuration called a short path evaporator, the condenser is placed internally, just a few centimeters from the heated wall.

This short distance means evaporated molecules travel to the condenser with minimal pressure drop, preventing them from re-condensing and falling back into the feed. It ensures a true low-pressure environment at the point of evaporation.

Key Advantages Explained

The unique design of a WFE creates a set of powerful advantages for challenging separation tasks.

Minimal Thermal Stress

The material is only exposed to the heated surface for a matter of seconds before it is either evaporated or exits as residue. This short residence time is the most critical advantage for heat-sensitive materials like pharmaceuticals, natural oils, and specialty chemicals.

Distillation of High-Boiling Point Compounds

The ability to operate under high vacuum makes it possible to distill materials that have extremely high boiling points. Compounds that would require dangerous or impractical temperatures to boil at atmospheric pressure can be easily purified in a WFE.

Efficient Processing of Viscous & Fouling Materials

In standard evaporators, viscous liquids flow poorly and can foul (burn onto) the heat transfer surfaces. The mechanical action of the wipers in a WFE forces the material to move, ensuring constant agitation and preventing the buildup of residue.

This allows for the processing of thick concentrates, polymers, and resins that would clog other systems.

Continuous and Efficient Operation

Unlike batch distillation, which involves heating a large volume for a long time, a WFE is a continuous system. Feed is constantly introduced and product/residue is constantly removed, making it highly efficient for industrial-scale production.

Understanding the Trade-offs and Limitations

No technology is perfect. The power of a WFE comes with specific considerations.

Higher Capital Investment

Wiped film evaporators are precision-engineered systems with tight tolerances and complex rotating assemblies. They represent a significantly higher upfront cost compared to simpler batch stills or rotary evaporators.

Mechanical Complexity and Maintenance

The internal rotating wipers require robust vacuum seals. These seals are wear components and represent a key point of maintenance and potential failure if not properly cared for.

Not Suited for Fine Fractionation

A WFE is primarily a separation tool for dividing materials into two streams: volatiles (the distillate) and non-volatiles (the residue). It is not designed to separate compounds with very close boiling points, a task better suited for a multi-stage fractional distillation column.

Sensitivity to Particulates

Solid particles in the feed material can damage the precisely machined wipers or the heated interior wall. Proper pre-filtration of the feed is almost always a requirement to ensure system longevity.

Making the Right Choice for Your Goal

Selecting a wiped film evaporator should be based on the specific properties of your material and your desired outcome.

- If your primary focus is purifying heat-sensitive, high-value compounds: A WFE is the industry standard for preventing degradation and maximizing the yield of active ingredients.

- If your primary focus is processing highly viscous materials or concentrates: The mechanical wiping action of a WFE is its unique and necessary advantage for ensuring flow and preventing fouling.

- If your primary focus is separating very high-boiling-point compounds from non-volatiles: A WFE's combination of high vacuum and short residence time is often the only practical way to perform the separation at manageable temperatures.

Ultimately, a wiped film evaporator is a powerful tool for achieving high-purity separations that are simply impossible with conventional methods.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Minimal Thermal Stress | Short residence time (seconds) prevents degradation of heat-sensitive materials. |

| High Vacuum Operation | Lowers boiling points, enabling distillation of high-boiling-point compounds. |

| Handles Viscous Materials | Mechanical wipers prevent fouling and ensure efficient processing of thick liquids. |

| Continuous Operation | Industrial-scale, efficient separation compared to batch methods. |

Need to Purify Heat-Sensitive or Viscous Materials?

KINTEK specializes in advanced laboratory equipment, including wiped film evaporators, designed to solve your most challenging separation problems. Our solutions help you maximize yield, preserve product integrity, and scale up your processes efficiently.

Contact our experts today to discuss how a wiped film evaporator can enhance your lab's capabilities and protect your high-value compounds.

Visual Guide

Related Products

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- 30T 40T Split Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What determines the vacuum degree achievable by a water circulating vacuum pump? Unlock the Physics of Its Limits

- How is a circulating water vacuum pump utilized for hydrogen production residues? Optimize Your Solid-Liquid Separation

- What is the purpose of the compression chamber in a vacuum pump? The Heart of Vacuum Generation

- What is the importance of a vacuum pump for Schottky hybrid interfaces? Achieve Atomic-Level Purity and Bonding

- Why is a water circulating vacuum pump suitable for handling flammable or explosive gases? Inherent Safety Through Isothermal Compression