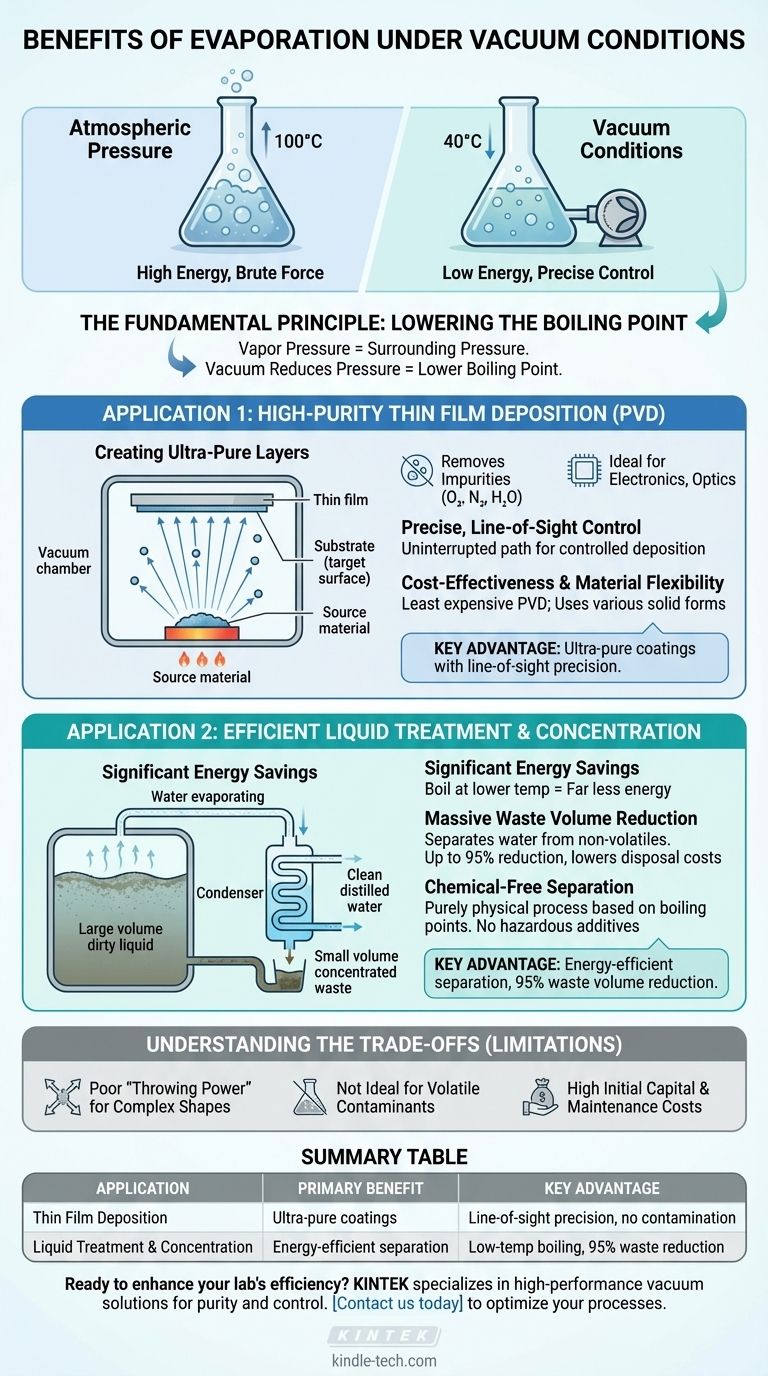

At its core, evaporating a substance under vacuum dramatically lowers its boiling point, which provides distinct advantages across two very different industrial applications. For manufacturing, this allows for the creation of ultra-pure thin film coatings with high precision. For environmental and chemical processing, it enables the highly efficient separation and concentration of liquids, such as treating wastewater, with significantly lower energy consumption than boiling at atmospheric pressure.

The primary benefit of using a vacuum is not the evaporation itself, but the control it provides. By lowering the required temperature, the process becomes less about brute-force heating and more about precise, efficient separation—whether you are separating atoms for a coating or water from a contaminant.

The Fundamental Principle: Why Use a Vacuum?

Evaporation is the process of a substance changing from a liquid or solid into a gas. Doing this in a vacuum—a space with extremely low pressure—fundamentally changes the physics involved.

Lowering the Boiling Point

The boiling point of a substance is the temperature at which its vapor pressure equals the pressure surrounding it. By creating a vacuum, you drastically reduce the surrounding pressure.

This means the substance can boil and evaporate at a much lower temperature. This single principle is the key that unlocks all the other benefits of the process.

Application 1: High-Purity Thin Film Deposition

In this context, often called Physical Vapor Deposition (PVD), a solid material is heated in a vacuum until it evaporates. The vapor then travels and condenses onto a target surface (the substrate), forming a solid, thin film.

Creating Ultra-Pure Layers

The vacuum environment is critical because it removes atmospheric gases like oxygen, nitrogen, and water vapor. These gases would otherwise react with the evaporated material and introduce impurities into the film.

This makes vacuum evaporation ideal for depositing high-purity films for electronics, optics, and protective coatings.

Precise, Line-of-Sight Control

In a vacuum, vaporized atoms travel in a straight, uninterrupted line from the source to the substrate.

This "line-of-sight" trajectory allows for highly controlled and precise deposition, essential for creating optical interference coatings, mirror surfaces, and conductive films.

Cost-Effectiveness and Material Flexibility

Compared to other PVD methods like sputtering, vacuum evaporation is often the least expensive process. It can also use source materials in virtually any solid form, adding to its flexibility.

Application 2: Efficient Liquid Treatment & Concentration

In this application, vacuum evaporation is used to separate water from dissolved substances or contaminants. The liquid is drawn into a vacuum chamber and heated, causing the water to boil off at a low temperature, leaving the contaminants behind.

Significant Energy Savings

Boiling large volumes of water at atmospheric pressure (100°C / 212°F) requires immense energy. By boiling it at a lower temperature under vacuum, the process consumes far less energy.

This makes it an economical solution for treating large volumes of industrial wastewater.

Massive Waste Volume Reduction

This method is exceptionally effective at separating pure water from contaminants that have a high boiling point. The result is a small, concentrated volume of waste and a large volume of recovered, distilled water.

Industries report wastewater volume reductions of up to 95%, dramatically lowering disposal costs and environmental impact.

Chemical-Free Separation

Vacuum evaporation is a purely physical process. It separates substances based on their different boiling points, eliminating the need for expensive and often hazardous chemical additives used in other treatment methods.

This is a major benefit in industries like food & beverage, pharmaceuticals, and metal finishing, where chemical contamination is a concern.

Understanding the Trade-offs

While powerful, vacuum evaporation is not a universal solution. Understanding its limitations is key to using it effectively.

Limitation 1: Poor "Throwing Power" for Coatings

The line-of-sight nature of PVD is also a weakness. It makes it difficult to uniformly coat complex, three-dimensional shapes with undercuts or hidden surfaces without sophisticated substrate rotation mechanisms.

Limitation 2: Not Ideal for All Contaminants

In liquid treatment, vacuum evaporation works best when separating a volatile liquid (like water) from non-volatile contaminants (like salts or heavy metals).

If the contaminant has a boiling point close to or lower than water (volatile organic compounds, for example), other separation methods may be required.

Limitation 3: Capital and Maintenance Costs

Vacuum systems, including pumps and chambers, represent a significant initial capital investment. They also require regular maintenance to ensure the integrity of the vacuum, which is critical to the process's efficiency and purity.

Making the Right Choice for Your Application

Your goal determines which benefits of vacuum evaporation are most relevant to you.

- If your primary focus is creating high-purity coatings: Choose vacuum evaporation for its exceptional purity, precise control, and cost-effectiveness, especially for coating flat or simply-curved surfaces.

- If your primary focus is treating challenging wastewater: Use vacuum evaporation to drastically reduce waste volume and recover clean water, particularly when dealing with non-volatile contaminants.

- If your primary focus is concentrating a valuable product: This process is ideal for gently removing a solvent (like water) at low temperatures to concentrate a heat-sensitive product without degrading it.

Ultimately, leveraging a vacuum transforms evaporation from a simple heating process into a highly controlled tool for purification and separation.

Summary Table:

| Application | Primary Benefit | Key Advantage |

|---|---|---|

| Thin Film Deposition | Ultra-pure coatings | Line-of-sight precision, no atmospheric contamination |

| Liquid Treatment & Concentration | Energy-efficient separation | Low-temperature boiling, 95% waste volume reduction |

Ready to enhance your lab's efficiency with precision vacuum evaporation? KINTEK specializes in high-performance lab equipment for thin film deposition and liquid separation. Our vacuum solutions deliver the purity and control your laboratory demands. Contact us today to explore how our expertise can optimize your processes!

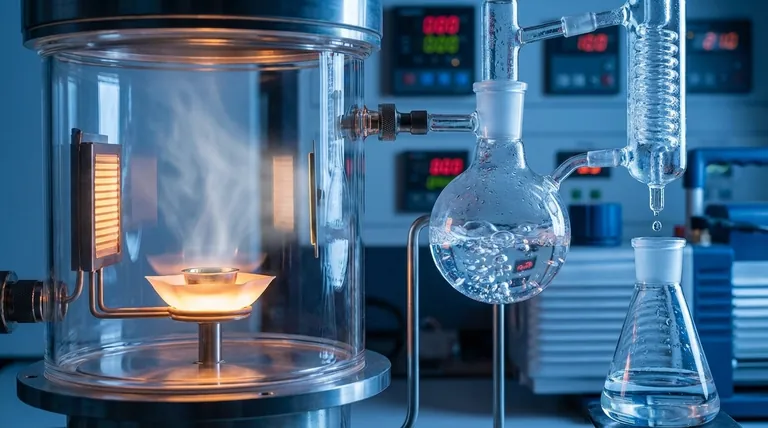

Visual Guide

Related Products

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- Tungsten Evaporation Boat for Thin Film Deposition

People Also Ask

- What is film uniformity? The Key to Consistent Device Performance and Yield

- Why KBr is used for making pellets to do IR measurements? Achieve Clear, Accurate Spectra

- Will THC distillate dissolve in water? Unlocking the Science of Water-Soluble Cannabis

- Why does graphite not melt? Unlocking the Secrets of Its Extreme Heat Resistance

- What are the components of rotavap? Master the Core System for Efficient Solvent Removal

- What are the limitations of magnetron sputtering? Key Trade-offs in Thin Film Deposition

- What are the advantages and applications of sintering process? Achieve Strong, Complex Parts Efficiently

- Why is it necessary to use a mechanical stirrer or shaker during azo dye degradation experiments? Optimize Your Results