At their core, the primary disadvantages of continuous reactors stem from their inherent lack of flexibility, high initial capital cost, and complexity in operation and maintenance. Unlike their batch counterparts, continuous systems are purpose-built for a single, high-volume process, making them ill-suited for variable production demands, multi-product manufacturing, or processes involving challenging materials like solids.

The decision to use a continuous reactor is fundamentally a trade-off. You sacrifice operational flexibility and low upfront investment in exchange for high-throughput efficiency, product consistency, and lower operating costs at a massive scale. The disadvantages become most apparent when these conditions for scale and consistency are not met.

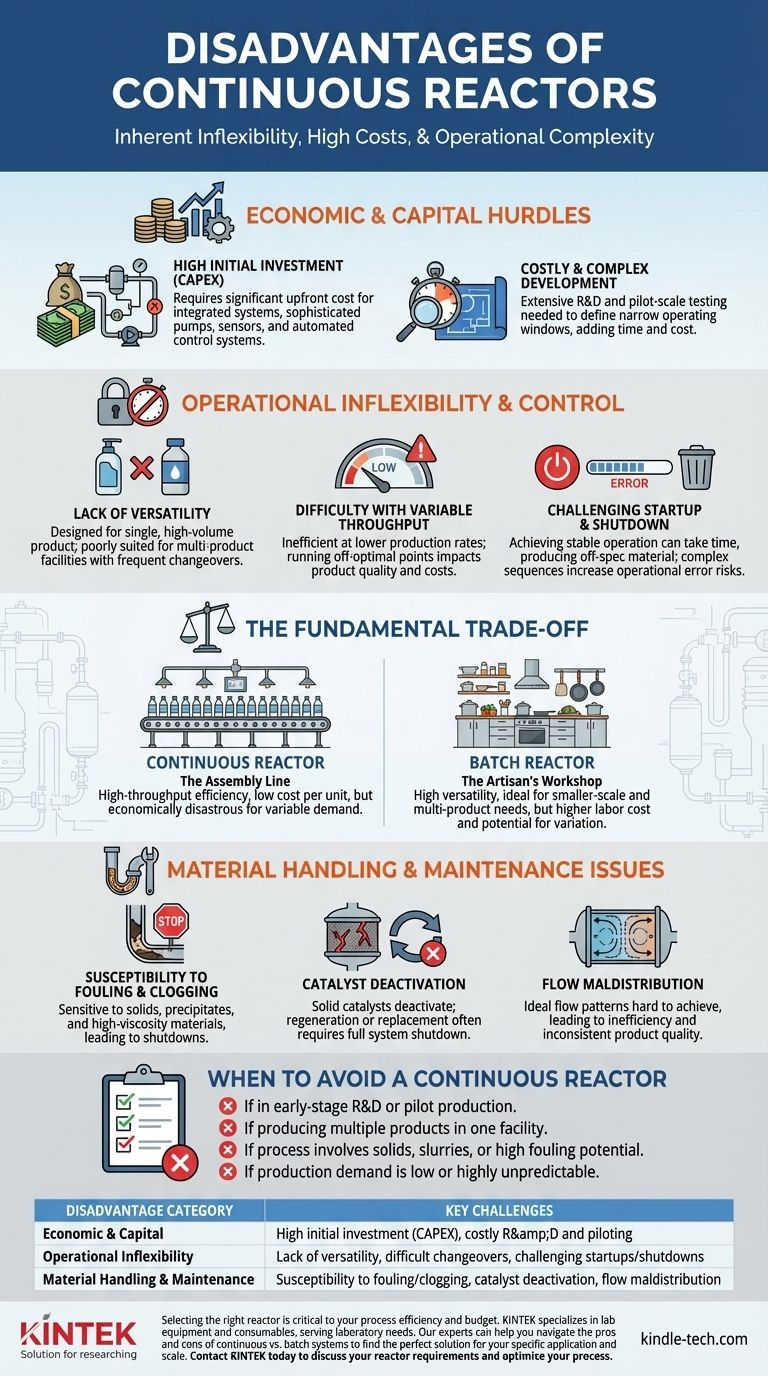

The Economic & Capital Hurdles

Continuous reactors represent a significant long-term commitment. Their economic disadvantages are most prominent before and during the initial phases of a project.

High Initial Investment (CAPEX)

A continuous process is more than just the reactor vessel. It is an entire integrated system.

This requires substantial upfront investment in sophisticated pumps, sensors, flow controllers, and automated control systems (like DCS or PLC) to maintain a precise steady state.

Costly and Complex Development

Optimizing a continuous process is far more involved than a batch process.

Significant R&D and pilot-scale testing are required to define the narrow operating window, which adds considerable time and cost to the development lifecycle.

Operational Inflexibility and Control

Once built, a continuous reactor is optimized for one specific task. Deviating from this task introduces significant inefficiencies and challenges.

Lack of Versatility

These systems are designed for a single product at a specific, high-volume production rate.

They are poorly suited for multi-product facilities that require frequent changeovers. Cleaning and re-validating a continuous system between different products is a slow and costly endeavor.

Difficulty with Variable Throughput

Continuous reactors have an optimal operating point.

Running them at significantly lower production rates than they were designed for leads to inefficiency, poor product quality, and negates their economic advantages over batch processing.

Challenging Startup and Shutdown Procedures

Achieving a stable, steady-state operation can take hours or even days, during which the process produces off-spec material that must be discarded or reprocessed.

These complex startup and shutdown sequences also increase the risk of operational errors.

The Fundamental Trade-off: Efficiency vs. Flexibility

The choice between a continuous and a batch reactor is not about which is universally "better," but which is appropriate for the specific industrial context.

Continuous Reactors: The Assembly Line

Think of a continuous reactor as a highly optimized assembly line, like one in a bottling plant. It does one thing exceptionally well and at a massive scale, leading to a very low cost per unit.

The downside is that you cannot easily re-tool this line to produce something else, and it's economically disastrous to run it for only an hour a day.

Batch Reactors: The Artisan's Workshop

A batch reactor is like a chef's kitchen. It is incredibly versatile. You can use the same equipment (pots, pans, oven) to cook a wide variety of different meals in different quantities.

This flexibility is ideal for smaller-scale production, new product development, and manufacturing high-value, low-volume chemicals like pharmaceuticals. The trade-off is higher labor cost per unit and potential for batch-to-batch variation.

Material Handling and Maintenance Issues

The physical operation of a continuous system introduces unique challenges that can lead to significant downtime if not managed properly.

Susceptibility to Fouling and Clogging

Continuous reactors, especially Plug Flow Reactors (PFRs) with narrow tubes, are highly sensitive to processes that involve solids, precipitates, or highly viscous materials.

Fouling on heat transfer surfaces or catalyst beds, or the outright clogging of flow paths, can force a complete shutdown of the entire process for cleaning, leading to major production losses.

Catalyst Deactivation

In many continuous processes using solid catalysts, the catalyst deactivates over time.

Regenerating or replacing this catalyst often requires a full system shutdown, which is a major operational event. Designing systems with parallel reactors to allow for this adds even more to the initial capital cost.

Flow Maldistribution

Ideal flow patterns (perfect mixing in a CSTR, no axial mixing in a PFR) are difficult to achieve in reality.

Phenomena like channeling, bypassing, or the creation of dead zones within the reactor can drastically reduce its efficiency and lead to inconsistent product quality, undermining the primary benefits of the system.

When to Avoid a Continuous Reactor

Based on these disadvantages, you can make a clear decision about whether a continuous system is a poor fit for your goals.

- If you are in early-stage R&D or pilot production: The inflexibility and high cost of a continuous setup make versatile batch reactors the superior choice.

- If you need to produce multiple products in one facility: The long and expensive changeover times associated with continuous systems make them economically unviable.

- If your process involves solids, slurries, or high fouling potential: The risk of clogging and the resulting downtime often outweighs the benefits of continuous operation unless a highly specialized (and expensive) design is used.

- If your production demand is low or highly unpredictable: Continuous reactors lose their cost advantage when operated below their designed capacity, making batch a safer financial choice.

Understanding these limitations is the first step toward selecting the right processing strategy for your specific chemical manufacturing goals.

Summary Table:

| Disadvantage Category | Key Challenges |

|---|---|

| Economic & Capital | High initial investment (CAPEX), costly R&D and piloting |

| Operational Inflexibility | Lack of versatility, difficult changeovers, challenging startups/shutdowns |

| Material Handling & Maintenance | Susceptibility to fouling/clogging, catalyst deactivation, flow maldistribution |

Selecting the right reactor is critical to your process efficiency and budget. KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you navigate the pros and cons of continuous vs. batch systems to find the perfect solution for your specific application and scale. Contact KINTALK today to discuss your reactor requirements and optimize your process.

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Spark Plasma Sintering Furnace SPS Furnace

- Customizable CO2 Reduction Flow Cell for NRR ORR and CO2RR Research

- Custom PTFE Teflon Parts Manufacturer for PTFE Containers

- Vacuum Dental Porcelain Sintering Furnace

People Also Ask

- What is the purpose of using high-purity argon gas in a high-pressure reactor? Ensure Precise Corrosion Test Data

- What role does an autoclave play in simulating PWR conditions? Advanced Material Validation for Nuclear Safety

- What is the role of high-pressure reactors in the study of alloy oxidation? Essential Tools for Supercritical Research

- Why are sealed laboratory reaction vessels necessary in the hydrothermal synthesis of zeolites? Ensure Purity and Yield

- Why are high-pressure autoclaves essential for preparing bio-based polyamide curing agents from dimeric acid?