The primary disadvantages of RF sputtering are its significantly lower deposition rates, higher system cost and complexity, and challenges in producing thick, low-stress films. Unlike the simpler Direct Current (DC) method, Radio Frequency (RF) sputtering requires an expensive power supply and an impedance matching network, making the entire process slower and more capital-intensive.

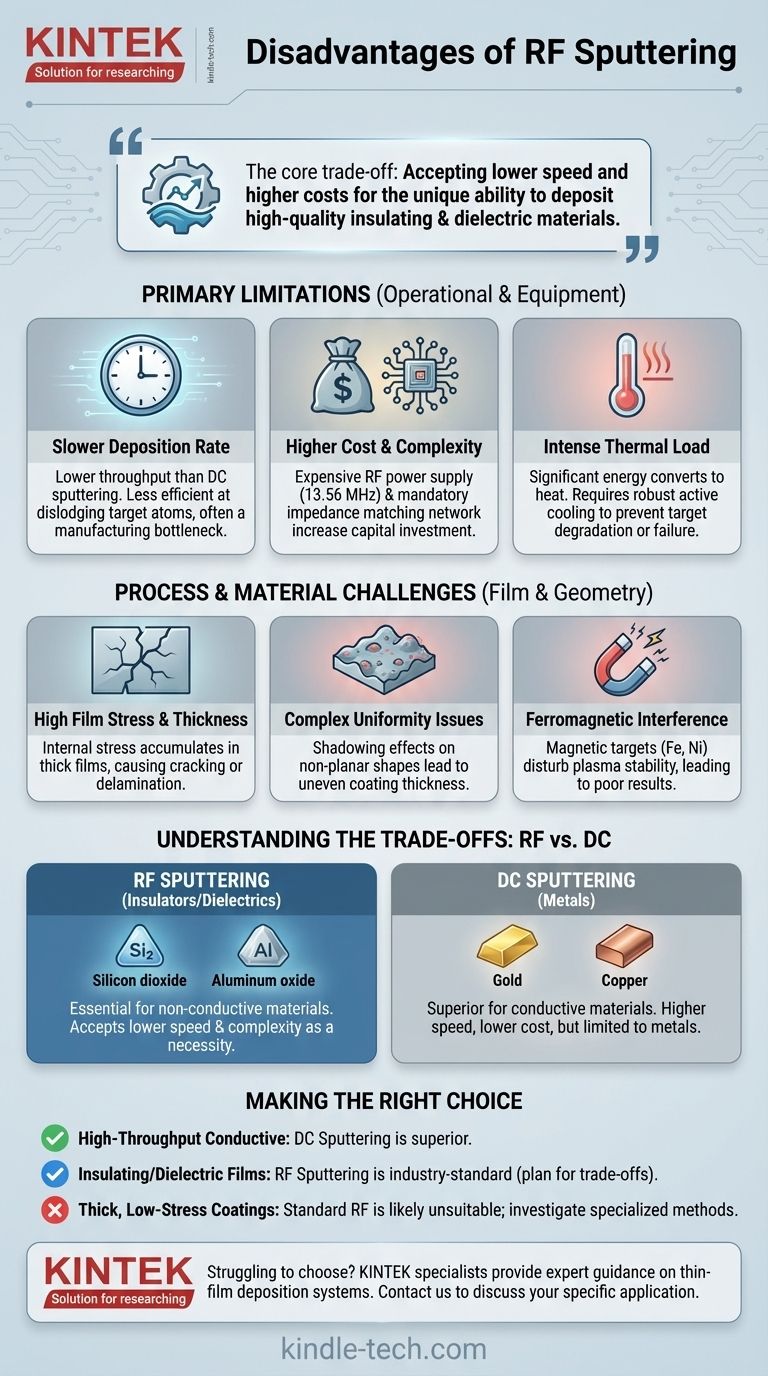

The core trade-off of RF sputtering is accepting lower speed and higher costs in exchange for the unique ability to deposit high-quality insulating and dielectric materials, a task that simpler methods like DC sputtering cannot perform.

The Primary Limitations of RF Sputtering

While versatile, the RF sputtering process comes with inherent drawbacks related to its operational physics and equipment requirements.

Deposition Rate

The most frequently cited disadvantage is the slow deposition rate. Compared to DC sputtering for conductive materials, RF sputtering is fundamentally less efficient at dislodging target atoms for a given power input.

While adding magnets (RF magnetron sputtering) can improve the rate by trapping electrons, it often remains a bottleneck for high-throughput manufacturing.

Cost and System Complexity

RF sputtering systems are significantly more expensive and complex than their DC counterparts. This is driven by two key components.

First is the RF power supply, which operates at a federally regulated frequency (typically 13.56 MHz) and is more costly to manufacture. Second is the required impedance matching network, a critical and complex device that ensures maximum power is transferred from the supply to the plasma, preventing power reflection that could damage the equipment.

Thermal Management

A large portion of the energy applied to the sputtering target is converted into heat rather than kinetic energy for sputtering atoms. This intense thermal load must be actively removed with a robust cooling system.

Inefficient cooling can lead to target degradation, inconsistent deposition rates, and even catastrophic failure of the target bonding.

Process and Material-Specific Challenges

Beyond the primary limitations, several challenges arise during the deposition process itself, especially with certain materials or film requirements.

Film Stress and Thickness

RF-sputtered films often exhibit high internal residual stress. While manageable for thin coatings, this stress accumulates as the film gets thicker.

This makes it very difficult to produce thick, high-performance coatings without issues like cracking, peeling, or delamination from the substrate.

Uniformity on Complex Geometries

Achieving a perfectly uniform coating on substrates with complex, non-planar shapes is a significant challenge. The directional nature of the sputtering process can lead to shadowing effects, causing thicker films on surfaces facing the target and thinner films on others.

Issues with Ferromagnetic Targets

When sputtering magnetic materials like iron or nickel, the target's own magnetic field can interfere with the RF process and any magnetron confinement. This can disturb the plasma, leading to process instability and poor deposition results.

Understanding the Trade-offs: RF vs. DC Sputtering

The disadvantages of RF sputtering are best understood in the context of its primary alternative, DC sputtering. The choice between them is almost always dictated by the target material.

The Core Difference: Target Material

DC sputtering can only be used for conductive materials (metals). If a direct current is applied to an insulating target, positive charge builds up on its surface, effectively stopping the sputtering process almost immediately.

RF sputtering solves this by using an AC field. The rapid oscillation of voltage prevents charge accumulation, making it the essential technique for depositing insulating and dielectric materials like silicon dioxide (SiO₂) or aluminum oxide (Al₂O₃).

Speed vs. Versatility

This creates a clear decision point. DC sputtering is the superior choice for metals due to its higher speed and lower cost. RF sputtering is the necessary choice for insulators, and its associated disadvantages are accepted as a required trade-off for its material versatility.

Making the Right Choice for Your Application

Selecting the correct sputtering technique requires aligning the process capabilities with your primary goal.

- If your primary focus is high-throughput deposition of conductive materials: DC magnetron sputtering is the clear choice for its superior speed and lower operational cost.

- If your primary focus is depositing insulating or dielectric films: RF sputtering is the industry-standard solution, and you must plan for the inherent trade-offs in speed and system complexity.

- If your primary focus is creating thick, low-stress coatings: Standard RF sputtering is likely unsuitable; you should investigate specialized low-stress deposition techniques or other methods entirely.

Ultimately, understanding these limitations allows you to choose the right deposition tool for your specific material and performance requirements.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Slower Deposition Rate | Lower throughput compared to DC sputtering for metals. |

| Higher Cost & Complexity | Expensive RF power supply and impedance matching network required. |

| High Film Stress | Difficult to produce thick coatings without cracking or delamination. |

| Thermal Management | Requires robust cooling to prevent target damage from heat buildup. |

Struggling to choose the right sputtering technique for your insulating or dielectric materials? KINTEK specializes in lab equipment and consumables, serving laboratory needs with expert guidance on thin-film deposition systems. Let our specialists help you navigate the trade-offs and select the optimal solution for your research or production goals. Contact us today to discuss your specific application and unlock the full potential of your lab!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- CVD Diamond Optical Windows for Lab Applications

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- 80L Chilling Circulator Cooling Water Circulator for Water Bath Cooling and Low Temperature Constant Temperature Reaction Bath

People Also Ask

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application

- What are the applications of sputtering targets? Key Uses in Electronics, Coatings & Energy

- What is meant by thin film in optics? Control Light with Nanoscale Precision

- Can you sputter silicon? A Guide to Silicon Thin-Film Deposition Methods

- What is diamond coated steel? A Guide to Ultra-Hard, Wear-Resistant Surfaces

- Can you coat something in diamond? Unlock Unmatched Hardness and Thermal Conductivity

- What is diamond coating? Boost Component Performance with Extreme Hardness & Low Friction

- What is the effect of deposition rate on thin film? Control Microstructure for Better Performance