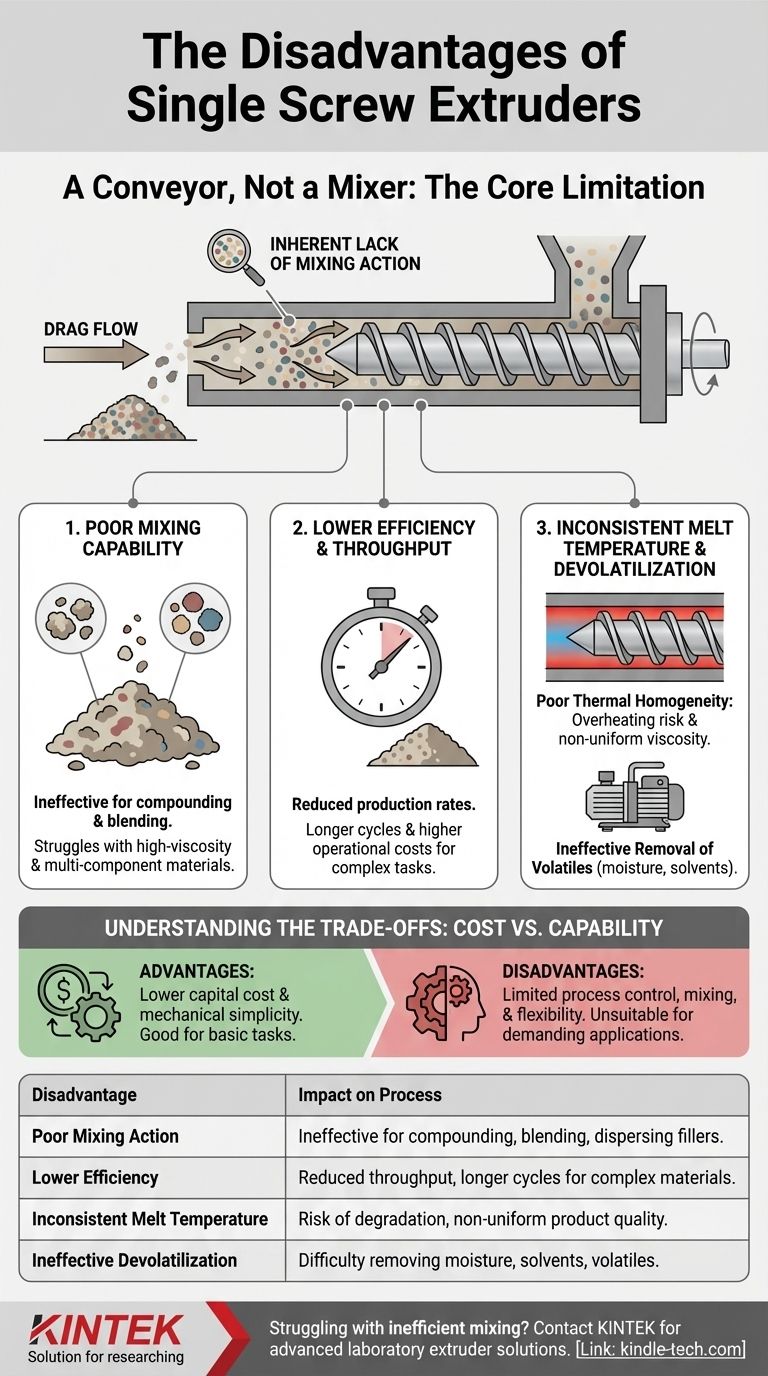

In short, the primary disadvantages of single screw extruders stem from their simple design, which leads to poor mixing capabilities, lower efficiency with complex materials, and limited process control. These limitations make them unsuitable for tasks that require intensive blending, high shear, or the processing of multi-component or high-viscosity polymers.

The simplicity that makes a single screw extruder reliable and cost-effective for basic tasks is also its greatest weakness. Its fundamental design as a conveyor, rather than a mixer, creates significant disadvantages in any process that demands material transformation, such as compounding or reactive extrusion.

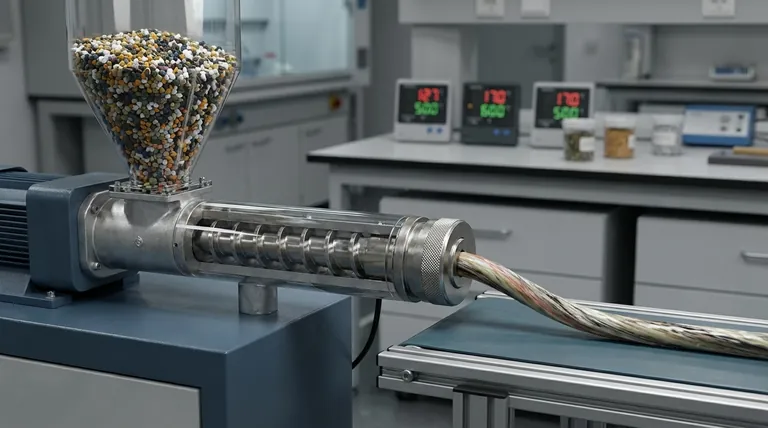

The Core Limitation: A Conveyor, Not a Mixer

The disadvantages of a single screw extruder are a direct result of its core mechanical function. It operates primarily on a principle called drag flow, where the material is dragged forward by the friction between the polymer and the rotating screw within a stationary barrel.

Inherent Lack of Mixing Action

A single screw's main job is to convey and melt material. It is not an effective mixer.

The material largely follows a spiral path down the barrel with very little cross-channel mixing. This is a stark contrast to a twin screw extruder, where intermeshing screws actively knead, shear, and turn the material over.

Poor Performance with Complex Materials

This limited mixing leads directly to issues with more demanding materials, as noted in the reference.

High-viscosity materials can slip against the screw or barrel, reducing forward motion and causing inconsistent output. Likewise, multi-component materials, such as polymer blends or filled compounds, often exit the extruder poorly dispersed, leading to inconsistent product quality.

Inefficiency and Process Control Challenges

The simple drag flow mechanism introduces several inefficiencies and makes precise process control difficult, especially when compared to more advanced systems.

Lower Production Efficiency

For a given size, a single screw extruder often has a lower throughput (output) rate than a twin screw extruder, particularly when processing complex compounds. The inability to generate high shear and intensive mixing means the process can be slow and inefficient.

This can result in longer production cycles and higher operational costs per pound of material processed.

Inconsistent Melt Temperature

A single screw extruder relies heavily on shear heating generated between the material and the stationary barrel. This can create poor thermal homogeneity.

The material near the barrel wall can become overheated, risking degradation, while the material closer to the screw root remains cooler. This temperature gradient makes it difficult to achieve a uniform melt viscosity, which is critical for product quality.

Difficulty with Devolatilization

Removing unwanted volatiles—such as moisture, solvents, or residual monomers—is very inefficient in a single screw extruder.

Effective devolatilization requires constantly exposing new surfaces of the molten polymer to a vacuum. The poor mixing action of a single screw fails to do this effectively, leaving volatiles trapped within the melt.

Understanding the Trade-offs

While the disadvantages are significant, it's crucial to see them in context. A single screw extruder is not a "bad" machine; it is a specialized tool that excels at specific tasks.

The Cost vs. Capability Dilemma

The primary advantage of a single screw extruder is its lower capital cost and mechanical simplicity. With fewer moving parts, it is cheaper to purchase, operate, and maintain than a twin screw extruder.

The key trade-off is sacrificing processing flexibility and mixing capability for cost-effectiveness and ease of use.

When to Avoid a Single Screw Extruder

The disadvantages become critical failures in certain applications. You should avoid a single screw design for:

- Compounding: Blending polymers with pigments, fillers, or additives.

- Reactive Extrusion: When a chemical reaction needs to occur within the extruder.

- High-Filler Content Materials: Processing materials with high levels of glass fiber, talc, or other fillers.

- Devolatilization-Intensive Processes: Removing significant amounts of moisture or solvents.

Making the Right Choice for Your Process

Choosing the right extruder depends entirely on the complexity of your material and your processing goals.

- If your primary focus is simple conveying of a single, uniform polymer: A single screw extruder is often the most cost-effective and reliable choice for applications like pipe, solid profiles, or sheet extrusion.

- If your primary focus is compounding, mixing, or reactive extrusion: The inherent mixing disadvantages make a twin screw extruder the necessary and far superior choice.

- If your primary focus is processing high-viscosity or filled materials: A single screw's low mixing efficiency will likely lead to poor product quality, making a twin screw a much safer investment.

Ultimately, you must match the capability of the tool to the complexity of the task.

Summary Table:

| Disadvantage | Impact on Process |

|---|---|

| Poor Mixing Action | Ineffective for compounding, blending, or dispersing fillers. |

| Lower Efficiency | Reduced throughput and longer cycles for complex materials. |

| Inconsistent Melt Temperature | Risk of material degradation and non-uniform product quality. |

| Ineffective Devolatilization | Difficulty removing moisture, solvents, or volatiles from the melt. |

Struggling with inefficient mixing or inconsistent output? Your process may require more advanced equipment. At KINTEK, we specialize in laboratory extruders and consumables designed for demanding applications like compounding and reactive extrusion. Our expertise can help you achieve superior material dispersion, precise temperature control, and higher throughput. Contact us today via our [#ContactForm] to discuss how our solutions can optimize your lab's extrusion processes and improve your product quality.

Visual Guide

Related Products

- Professional Cutting Tools for Carbon Paper Cloth Diaphragm Copper Aluminum Foil and More

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Single Punch Manual Tablet Press Machine TDP Tablet Punching Machine

- Powerful Plastic Crusher Machine

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

People Also Ask

- What are the advantages of a two roll mill? Achieve Superior Polymer Mixing & Quality Control

- What is the difference between extrusion coating and extrusion lamination? A Guide to Material Enhancement

- What is the difference between extrusion and co-extrusion? Engineer Multi-Material Parts

- What products are blown film extrusion? From Grocery Bags to Industrial Sheeting

- What is the difference between single layer film and multi layer film? A Guide to Material Selection

- What is the cost of blown film extrusion? From $20K to High-End Systems

- What fillers for rubber compounds? Choose the Right Filler for Performance vs. Cost

- What is short capacity of injection Moulding machine? Optimize Your Shot Size for Flawless Parts