The primary disadvantages of a twin screw extruder are its significantly higher cost and increased operational complexity compared to single screw alternatives. The intricate engineering required for the intermeshing screws and the sophisticated gearbox drives up both the initial purchase price and the long-term maintenance expenses.

A twin screw extruder's superior mixing and processing capabilities come with a clear trade-off: a higher total cost of ownership and a steeper learning curve for operators. The decision to use one is an investment in versatility at the expense of simplicity and economy.

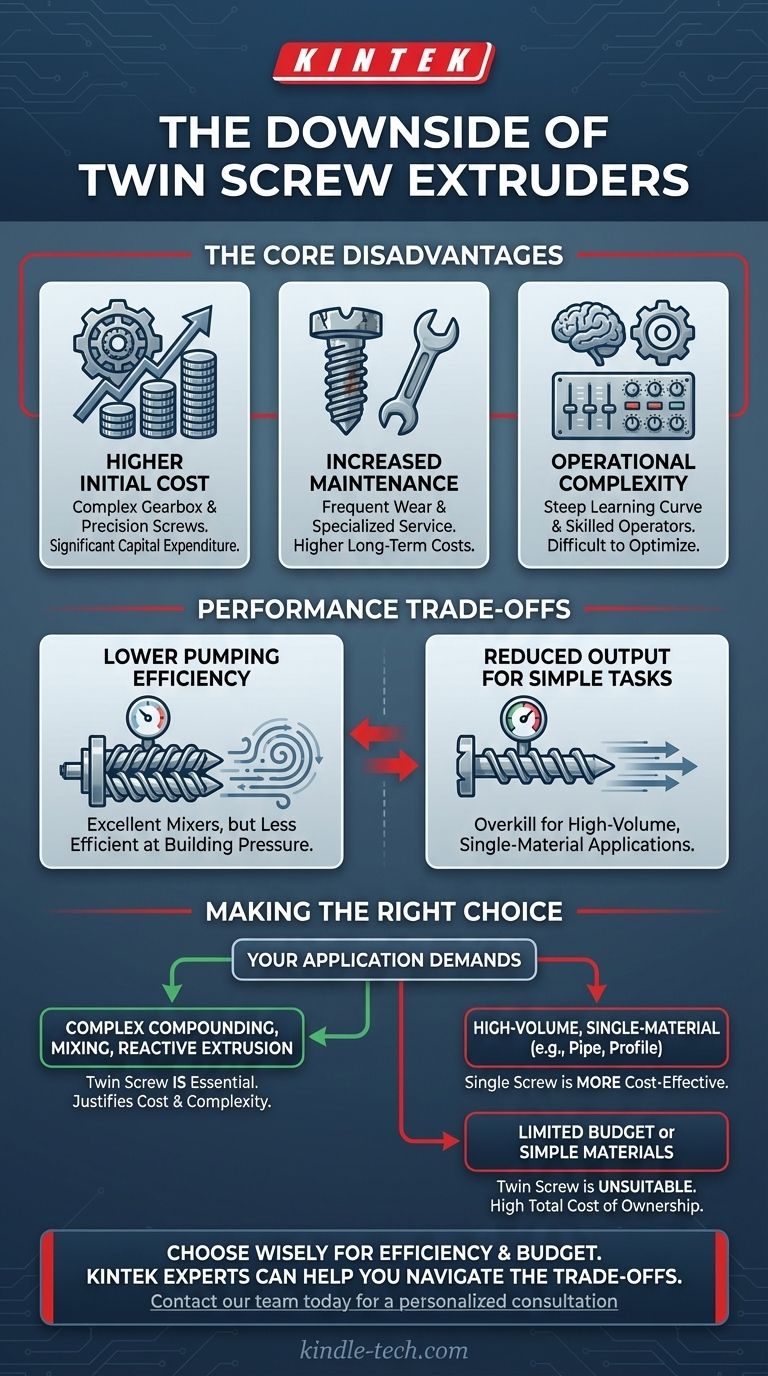

The Core Disadvantages Explained

While powerful, the design of a twin screw extruder introduces several fundamental challenges that are critical to understand before making an investment.

Higher Initial Cost

A twin screw extruder is a piece of precision machinery. The gearbox required to drive two intermeshing screws in a synchronized manner is far more complex and expensive to manufacture than the simple drive of a single screw machine.

The screw elements themselves must be machined to tight tolerances to ensure proper interaction, adding to the overall capital expenditure.

Increased Maintenance and Operating Costs

The mechanical complexity, particularly in the gearbox and the screw-barrel interface, leads to higher maintenance demands. Wear on the screw elements and barrel is a significant long-term cost.

Servicing these machines often requires more specialized knowledge and training compared to their simpler single screw counterparts, increasing labor costs and potential downtime.

Operational Complexity

Operating a twin screw extruder effectively requires a deeper understanding of polymer processing. The large number of variables—screw configuration, element selection, speed, and feed rate—creates a steep learning curve.

Achieving optimal performance is less straightforward, demanding more skilled operators to set up and fine-tune the process for a specific application.

Understanding the Performance Trade-offs

Beyond cost, twin screw extruders have inherent performance characteristics that can be disadvantageous in certain applications.

Lower Pumping Efficiency

Twin screw extruders are exceptional mixers but are generally less efficient at building pressure and conveying material forward (pumping) than a well-designed single screw extruder.

For applications where the primary goal is simply to melt and pump a material at high pressure, such as in pipe or simple profile extrusion, a single screw machine is often superior.

Reduced Output for Simple Tasks

The versatility of a twin screw extruder is overkill for simple, high-volume applications involving a single, easy-to-process material.

In these scenarios, a larger single screw extruder can often deliver higher throughput for a lower capital investment and less energy consumption.

Making the Right Choice for Your Goal

Evaluating these disadvantages against your specific processing needs is the key to making a sound investment.

- If your primary focus is complex compounding, mixing, or reactive extrusion: The superior processing capabilities of a twin screw extruder are often essential and justify the higher cost and complexity.

- If your primary focus is high-volume, single-material extrusion (e.g., pipe, sheet, or profiles): A single screw extruder is typically the more cost-effective and efficient choice.

- If your primary focus is working with a limited budget or simple materials: The high total cost of ownership and operational demands of a twin screw extruder make it an unsuitable option.

Ultimately, choosing the right extruder means matching the machine's capabilities and costs directly to the demands of your application.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Higher Initial Cost | More expensive due to complex gearbox and precision-machined screws. |

| Increased Maintenance | Higher long-term costs for specialized servicing and part replacement. |

| Operational Complexity | Steeper learning curve requires more skilled operators. |

| Lower Pumping Efficiency | Less effective at building pressure than single screw extruders. |

| Reduced Output for Simple Tasks | Overkill for high-volume, single-material processing. |

Choosing the right extruder is critical for your lab's efficiency and budget.

While a twin screw extruder offers superior mixing for complex tasks, its higher cost and complexity may not be justified for your application. The experts at KINTEK can help you navigate these trade-offs. We specialize in providing the right lab equipment, from single screw to twin screw extruders, ensuring you get the performance you need without unnecessary expense.

Let us help you optimize your process. Contact our team today for a personalized consultation and discover the KINTEK advantage in lab equipment solutions.

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Benchtop Laboratory Vacuum Freeze Dryer

- Custom PTFE Teflon Parts Manufacturer for PTFE Tweezers

People Also Ask

- What is the function of sieving equipment in CuAlMn alloys? Master Pore Size Precision

- What is the primary purpose of using standard sieves? Master Particle Uniformity for High-Quality Catalyst Preparation

- What is the primary function of a mechanical sieve shaker for biomass analysis? Optimize Particle Size Distribution

- What are the factors affecting sieving performance and efficiency? Optimize Your Particle Separation Process

- Why is sieve analysis important? Ensure Consistent Quality and Performance of Your Materials