At its core, autoclave maintenance is a multi-layered process that combines routine operational diligence with a schedule of periodic technical inspections. The goal is to ensure consistent sterilization performance, operator safety, and equipment longevity. This involves daily checks by users, detailed record-keeping in a logbook, and planned inspections of critical components like heating coils, steam traps, and safety valves on a monthly, quarterly, or annual basis.

The central principle of effective autoclave management is that true maintenance is not just a repair schedule, but a comprehensive program that integrates proper daily use, proactive inspections, and diligent record-keeping to prevent failures before they occur.

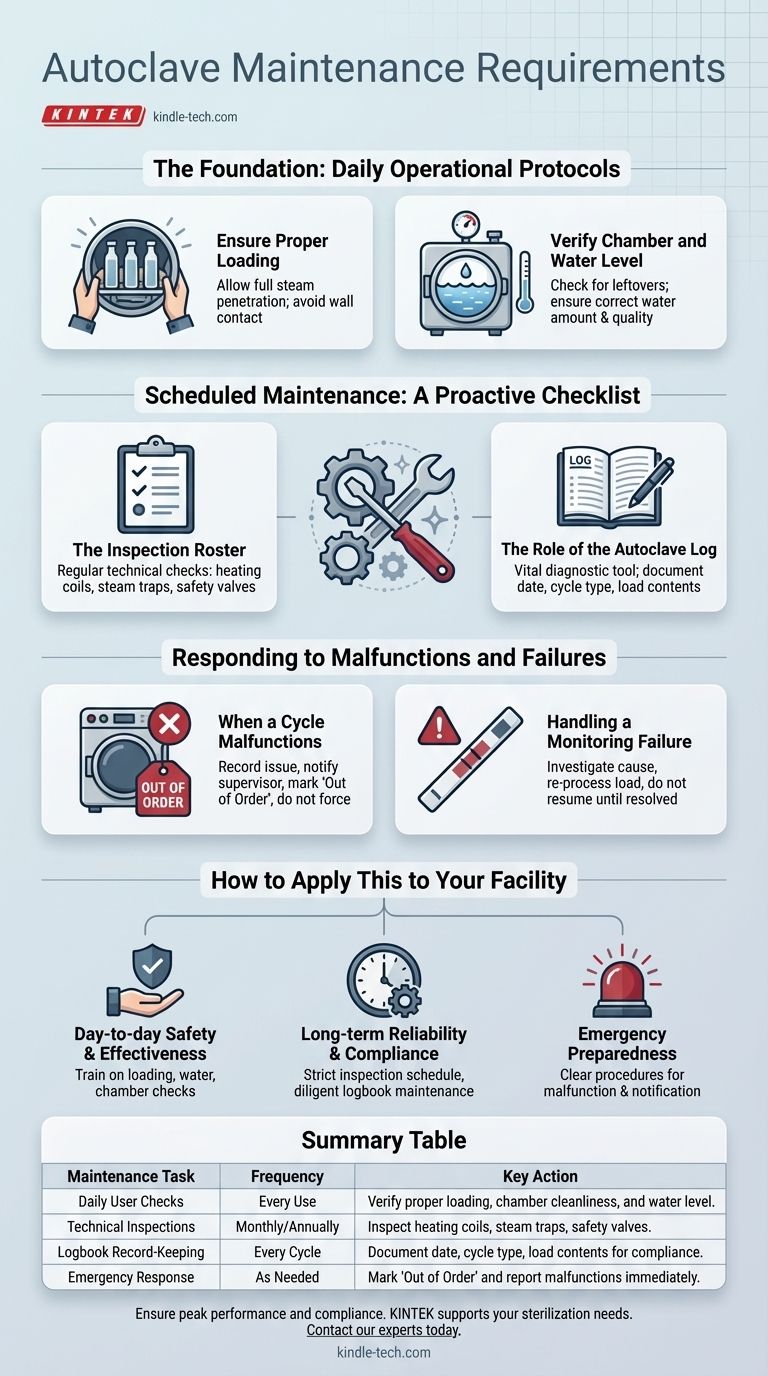

The Foundation: Daily Operational Protocols

Proper daily operation is the first line of defense in preventing unnecessary wear and tear. The user's actions directly impact the autoclave's performance and safety.

Ensure Proper Loading

Before starting a cycle, ensure all items are placed correctly. There must be enough space between each item to allow for full steam penetration.

Crucially, no materials should be touching the chamber walls or floor, as this can impede sterilization and potentially damage the items or the autoclave itself.

Verify Chamber and Water Level

Always check the chamber for any items left over from a previous cycle. A clean and empty chamber is essential for a valid run.

Ensure the correct amount of water is present according to the manufacturer's manual. Insufficient water can damage heating elements, while poor water quality can lead to particulate buildup over time.

Scheduled Maintenance: A Proactive Checklist

Beyond daily care, a formal inspection schedule is necessary to monitor the health of the autoclave’s core components. This is typically performed by trained personnel.

The Inspection Roster

Key components require regular technical inspection to ensure they are in proper working order.

This roster includes heating coils, electrical contactors, steam traps, and safety valves. These checks are scheduled at intervals—such as monthly, quarterly, or annually—based on the manufacturer's recommendations and usage frequency.

The Role of the Autoclave Log

Maintaining a detailed autoclave log sheet is a critical part of the maintenance program. It is not just an operational record but a vital diagnostic tool.

Each entry should document the date, time, cycle type, and contents of the load. This data helps monitor performance, aids in troubleshooting, and ensures compliance with safety standards from organizations like the CDC.

Responding to Malfunctions and Failures

Even with perfect maintenance, issues can arise. How you respond is critical to ensuring safety and resolving the problem effectively.

When a Cycle Malfunctions

If an autoclave malfunctions during a cycle, the first step is to record the issue in the logbook. Immediately notify the responsible supervisor or lab manager.

The unit must be clearly marked as "Out of Order." Do not attempt to diagnose or repair the issue yourself. Never try to force the safety lock mechanism to open the door.

Handling a Monitoring Failure

If a biological or chemical indicator fails, the sterilization of that load cannot be confirmed. The cause of the failure must be investigated and resolved.

The affected load must be set aside and re-processed in a validated cycle once the autoclave is confirmed to be operating correctly. Do not resume routine operations until the issue is resolved.

How to Apply This to Your Facility

A successful autoclave program balances the responsibilities of the daily user with the oversight of trained maintenance personnel. The goal is a system where safety and performance are actively managed, not just passively assumed.

- If your primary focus is day-to-day safety and effectiveness: Train all operators on proper loading techniques, water requirements, and the importance of checking the chamber before each use.

- If your primary focus is long-term reliability and compliance: Implement a strict schedule for technical inspections and make diligent logbook maintenance a non-negotiable part of your protocol.

- If your primary focus is emergency preparedness: Establish a clear, written procedure for what operators must do in the event of a malfunction, emphasizing safety and proper notification.

Ultimately, a well-maintained autoclave is the product of clear protocols that everyone understands and follows.

Summary Table:

| Maintenance Task | Frequency | Key Action |

|---|---|---|

| Daily User Checks | Every Use | Verify proper loading, chamber cleanliness, and water level. |

| Technical Inspections | Monthly/Annually | Inspect heating coils, steam traps, safety valves. |

| Logbook Record-Keeping | Every Cycle | Document date, cycle type, load contents for compliance. |

| Emergency Response | As Needed | Mark 'Out of Order' and report malfunctions immediately. |

Ensure your laboratory's autoclave operates at peak performance and compliance. Proper maintenance is critical for sterilization efficacy and safety. KINTEK specializes in high-quality lab equipment, including autoclaves, and provides expert support to keep your instruments running reliably. From selecting the right model to establishing a robust maintenance program, we are here to help. Contact our experts today to discuss your laboratory's sterilization needs and discover how we can support your success.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- What are the advantages of using an autoclave equipped with a stirring device for molten salt testing? Dynamic Accuracy

- What is the function of laboratory autoclaves in SCWR research? Predict Material Compatibility and Corrosion Kinetics

- What experimental conditions do stainless steel autoclaves provide for PCT-A leaching? Optimize Phosphate Glass Testing

- What is the primary function of a laboratory autoclave in the pre-treatment of medical plastic waste for liquid fuel?

- What is the primary function and principle of autoclaving? Master Lab Sterilization with High-Pressure Steam