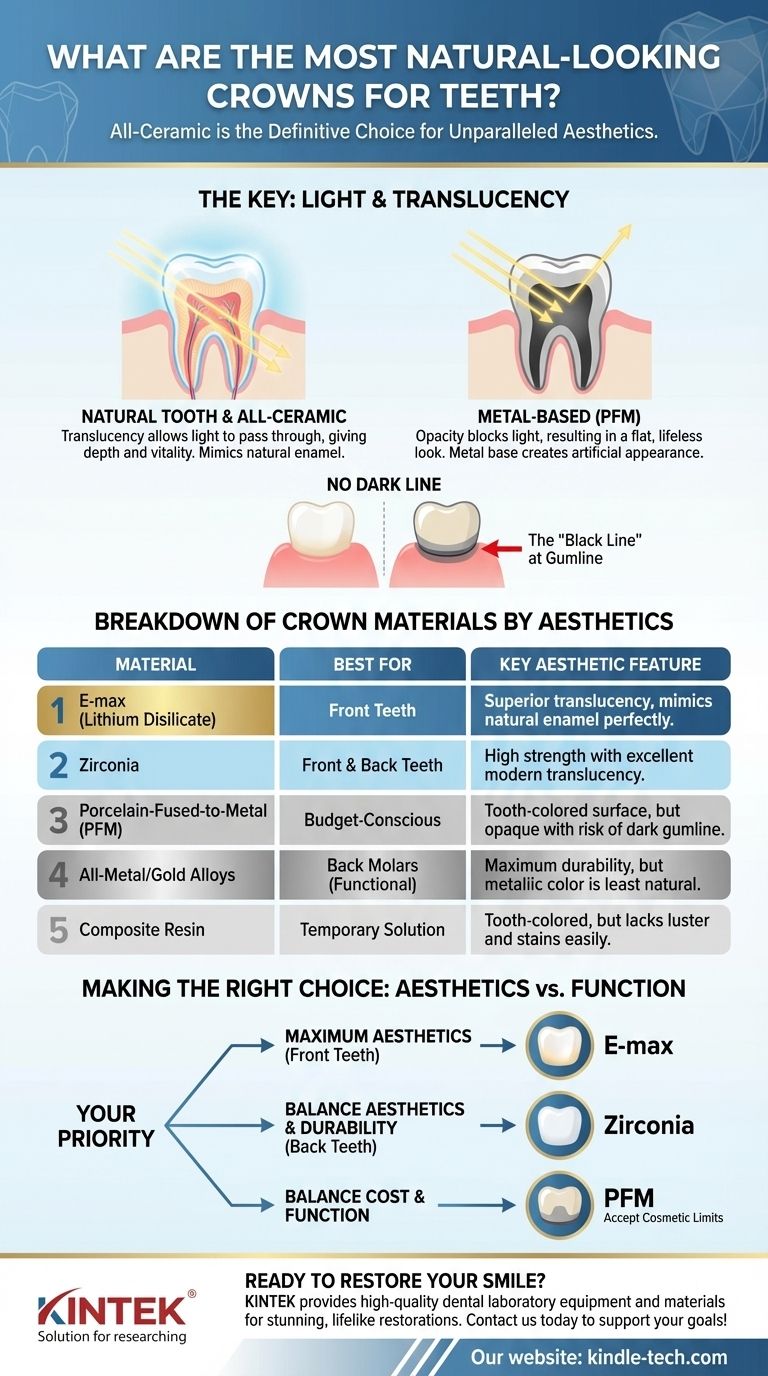

For the most natural-looking dental crown, all-ceramic is the definitive choice. Materials like E-max (lithium disilicate) and Zirconia possess translucent qualities that mimic natural tooth enamel, allowing light to pass through and interact with them in a realistic way. This optical property is what eliminates the flat, opaque appearance common with older crown technologies that rely on a metal base.

The secret to a natural-looking crown isn't just about matching the color; it's about the material's ability to replicate the translucency and light-handling properties of a real tooth. All-ceramic crowns excel at this, while metal-based options inherently create an artificial look that blocks light.

What Defines a "Natural-Looking" Crown?

To choose the best crown, it's important to first understand what creates a natural appearance in a tooth. The aesthetics go far beyond simple color.

It's All About Light

A natural tooth is not fully opaque. It has a degree of translucency, meaning light can pass partway through the enamel before bouncing back out. This is what gives teeth their depth and vitality.

The most realistic crowns are made from materials that can replicate this effect. Opaque materials block light completely, resulting in a flat, lifeless look that is easily identifiable as a crown.

Avoiding the "Black Line"

A common aesthetic concern is the dreaded dark line at the gumline. This is almost always caused by a Porcelain-Fused-to-Metal (PFM) crown, where the underlying metal edge becomes visible if the gums recede even slightly.

All-ceramic crowns have no metal substructure, completely eliminating this possibility and ensuring a seamless transition from crown to gum.

A Breakdown of Crown Materials by Aesthetics

Each crown material offers a different balance of appearance, strength, and cost. Here, we'll evaluate them based purely on their ability to look natural.

The Gold Standard: All-Ceramic (E-max & Zirconia)

These crowns are crafted from a single block of advanced ceramic material, making them the top tier for aesthetics.

E-max (Lithium Disilicate) is often considered the most beautiful material. Its high translucency is an exceptional match for natural tooth enamel, making it the premier choice for highly visible front teeth.

Zirconia is another excellent ceramic known for its incredible strength, often called "ceramic steel." While historically slightly more opaque than E-max, modern formulations offer excellent translucency, making it a fantastic choice for both front and back teeth where durability is paramount.

The Compromise: Porcelain-Fused-to-Metal (PFM)

PFM crowns have been a reliable standard for decades. They consist of a metal alloy base with a layer of porcelain baked on top.

While the porcelain provides a tooth-colored surface, the metal underneath completely blocks light. This inherent opacity can make the crown look less vibrant than its neighbors. The potential for the dark line at the gums is its biggest cosmetic drawback.

The Functional Choice: All-Metal and Gold Alloys

These crowns are known for their exceptional durability and longevity. They require less tooth structure to be removed and are very gentle on opposing teeth.

From a purely aesthetic standpoint, however, they are the least natural-looking option due to their metallic color. They are almost exclusively used for out-of-sight molars.

The Short-Term Solution: Composite Resin

Composite resin crowns are less expensive but also less durable than ceramic or metal. They are more susceptible to wear and staining over time.

While they are tooth-colored, they lack the luster and realistic translucency of high-end ceramics. They are generally considered a less permanent solution.

Understanding the Trade-offs

The most natural-looking option is not always the right choice for every situation. Functionality and location are critical factors.

Aesthetics vs. Durability

While E-max is often the most beautiful, Zirconia is significantly stronger. For a patient who grinds their teeth or for a molar that endures immense chewing forces, Zirconia is often the more durable and practical ceramic choice.

The Impact of Location

The demands on a front tooth are primarily cosmetic. The demands on a back molar are primarily functional. This is why an E-max crown might be recommended for an incisor, while a Zirconia or even a gold crown might be recommended for a second molar.

The Role of the Dentist and Lab

The final result depends heavily on the skill of your dentist and the dental laboratory that fabricates the crown. A great ceramist can make a good material look exceptional, perfectly matching the color, shade, and subtle characterizations of your adjacent teeth.

Making the Right Choice for Your Goal

Selecting the right crown involves matching the material's properties to your specific priority and the tooth's location.

- If your primary focus is maximum aesthetics for a front tooth: E-max (lithium disilicate) is typically the superior choice for its unparalleled translucency and natural appearance.

- If your primary focus is an aesthetic crown for a back tooth: Monolithic Zirconia offers a durable, tooth-colored solution that can withstand heavy biting forces.

- If your primary focus is a balance between cost and function: A PFM crown is a time-tested option, but you must accept its cosmetic limitations and the risk of a visible metal margin.

Ultimately, the best crown is one that restores function while making you feel completely confident in your smile.

Summary Table:

| Material | Best For | Key Aesthetic Feature |

|---|---|---|

| E-max (Lithium Disilicate) | Front Teeth | Superior translucency, mimics natural enamel |

| Zirconia | Front & Back Teeth | High strength with excellent modern translucency |

| Porcelain-Fused-to-Metal (PFM) | Budget-Conscious | Tooth-colored surface, but opaque with risk of dark gumline |

| All-Metal/Gold | Back Molars | Maximum durability, but metallic color |

| Composite Resin | Temporary Solution | Tooth-colored, but lacks luster and stains easily |

Ready to Restore Your Smile with a Natural-Looking Crown?

Choosing the right crown material is essential for both the health of your tooth and your confidence. At KINTEK, we specialize in providing high-quality dental laboratory equipment and materials that help dental professionals create stunning, durable, and lifelike restorations. Whether you're a dentist seeking the best ceramics for your practice or a lab technician crafting the perfect crown, we have the solutions to meet your needs.

Let us help you achieve exceptional results.

Contact us today to learn more about our products and how we can support your dental restoration goals!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is one of the newest applications for dental ceramics? Monolithic Zirconia for Full-Arch Bridges

- What makes zirconia translucent? The Science Behind Modern Dental Aesthetics

- What is the effect of zirconia sintering temperature? Master the Key to Strength and Stability

- What is the sintering time for zirconia? A Guide to Precise Firing for Optimal Results

- Can you change the color of zirconia crowns? Understanding the Permanent Nature of Zirconia