To ensure accurate results and proper equipment function, the primary precautions for using a sieve shaker involve understanding the method's limitations and performing diligent maintenance. This includes acknowledging the instrument's reduced accuracy for particles under 50-100 µm, recognizing its bias against non-spherical particles, and regularly inspecting sieves for clogging or distortion that can invalidate your analysis.

The most critical precaution is intellectual, not mechanical. You must recognize that a sieve shaker provides a rapid, cost-effective estimate of particle size distribution, but its accuracy is fundamentally limited by particle shape and fineness.

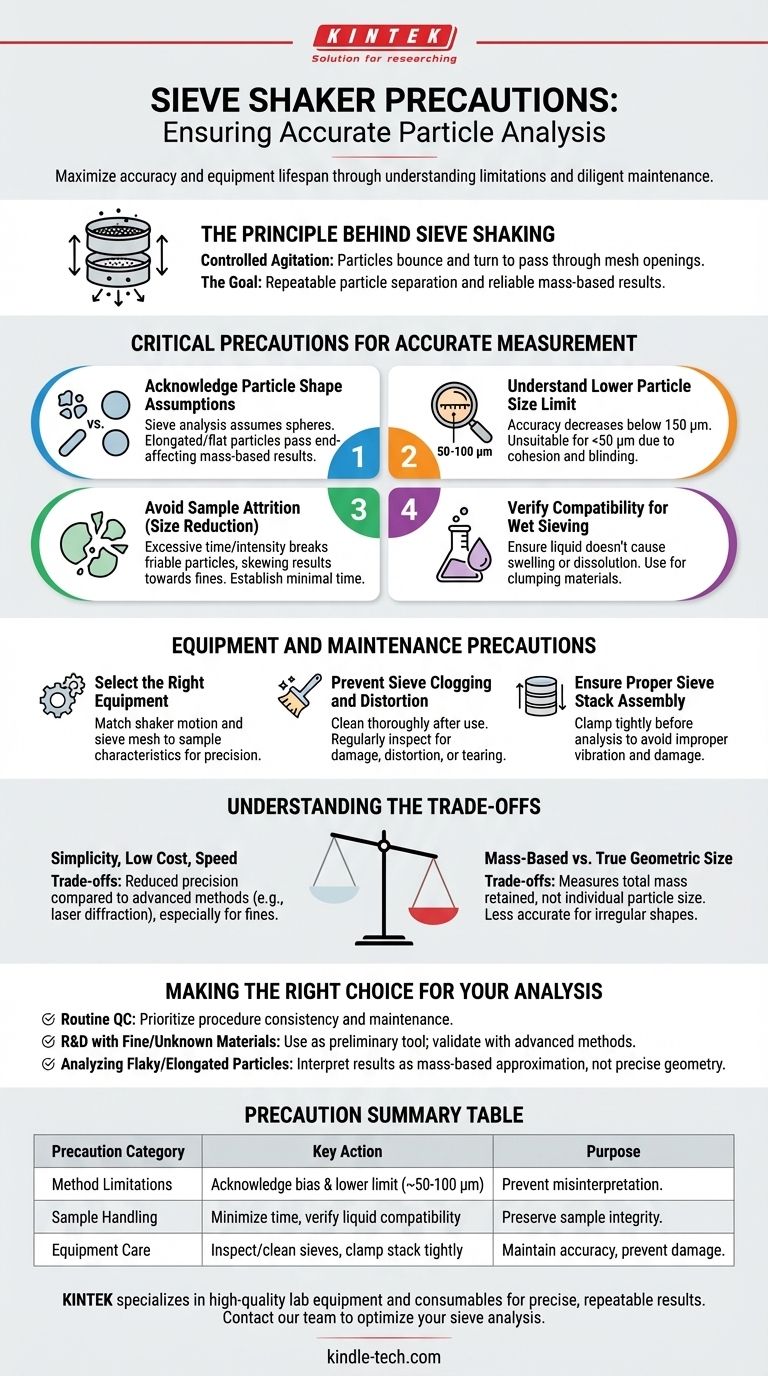

The Principle Behind Sieve Shaking

To apply precautions effectively, you must first understand the operational goal: creating repeatable particle separation through controlled agitation.

The Mechanics of Separation

A sieve shaker uses a vibration motor to impart a specific motion—ideally a 3-D or orbital movement—to a stack of test sieves.

This agitation causes particles to bounce and turn, giving them opportunities to pass through the mesh openings of a sieve.

Particles smaller than the mesh openings fall to the next sieve below, continuing until they are retained on a sieve with openings too small for them to pass.

The Goal: Consistent and Repeatable Results

The entire process is designed to sort a material sample by size, allowing you to determine its particle size composition by weighing the material retained on each sieve. The core objective is to achieve results that are repeatable and reliable for a given material.

Critical Precautions for Accurate Measurement

The most significant errors in sieve analysis arise from a misunderstanding of the method's inherent assumptions and limitations. These precautions are vital for data integrity.

Acknowledge Particle Shape Assumptions

The fundamental assumption of sieve analysis is that all particles are perfect spheres. This is rarely true.

Elongated and flat particles may pass through mesh openings end-on or on-edge, reporting a smaller size than their actual dimensions. This leads to unreliable mass-based results for materials with irregular shapes.

Understand the Lower Particle Size Limit

Sieve shakers are highly effective for coarse materials but lose accuracy significantly for very fine powders.

For particles smaller than 100 mesh (150 µm), accuracy begins to decrease. Below 50 µm, the method is generally considered unsuitable due to particle cohesion and screen-blinding effects.

Avoid Sample Attrition (Size Reduction)

Excessive shaking time or intensity can cause friable (brittle) particles to break down. This is known as sample attrition.

This error creates more fine particles than were originally in the sample, skewing the distribution towards smaller sizes. Always establish a standard, minimal sieving time for your specific material.

Verify Compatibility for Wet Sieving

Wet sieve analysis can be used for materials that clump or have electrostatic charges, but you must take a critical precaution.

Ensure the liquid used for dispersion (typically water or alcohol) does not cause the material to swell, dissolve, or otherwise change its physical characteristics.

Equipment and Maintenance Precautions

Proper care of your sieve shaker and test sieves is non-negotiable. Damaged or dirty equipment will always produce flawed results.

Select the Right Equipment

Your first precaution is choosing the correct tool. The shaker's motion and the sieve mesh sizes must be appropriate for the size and characteristics of the sample you are analyzing.

Electromagnetic shakers, for instance, are often recommended for tests requiring a higher degree of precision and repeatability.

Prevent Sieve Clogging and Distortion

After each use, sieves must be thoroughly cleaned according to established procedures. Trapped particles (clogging) effectively reduce the mesh opening size and will bias your next analysis.

Regularly inspect sieve mesh for any signs of distortion, sagging, or tearing. A damaged sieve must be removed from service immediately as it will produce invalid results.

Ensure Proper Sieve Stack Assembly

Before starting an analysis, ensure the stack of sieves is assembled correctly and clamped tightly onto the shaker base.

A loose stack will vibrate improperly, leading to poor separation, inconsistent results, and potential damage to the sieves or shaker.

Understanding the Trade-offs

A sieve shaker is a valuable tool, but its utility comes with clear trade-offs. Being aware of them is essential for interpreting your data correctly.

Accuracy vs. Simplicity

The primary advantage of a sieve shaker is its simplicity, low cost, and speed. However, this comes at the cost of precision compared to more advanced methods like laser diffraction, especially for fine or non-spherical particles.

Mass-Based vs. True Geometric Size

Remember that you are not measuring individual particles. You are measuring the total mass of particles that were retained on a screen of a certain size. For irregularly shaped materials, this mass distribution may not accurately reflect the true geometric size distribution.

Making the Right Choice for Your Analysis

Apply these precautions based on the goal of your measurement.

- If your primary focus is routine quality control: A sieve shaker is an excellent tool; prioritize establishing a consistent procedure, sieving time, and a strict maintenance schedule.

- If your primary focus is R&D with fine or unknown materials: Use the sieve shaker as a preliminary tool and be prepared to validate your findings with a more advanced particle sizing method.

- If your primary focus is analyzing flaky or elongated particles: Understand that your results are a mass-based approximation and should not be interpreted as a precise geometric measurement.

By treating the sieve shaker with an understanding of its principles and limitations, you can ensure it remains a reliable asset in your analytical toolkit.

Summary Table:

| Precaution Category | Key Action | Purpose |

|---|---|---|

| Method Limitations | Acknowledge bias against non-spherical particles and lower size limit (~50-100 µm). | Prevent misinterpretation of results. |

| Sample Handling | Use minimal sieving time to avoid attrition; verify liquid compatibility for wet sieving. | Preserve sample integrity and prevent particle breakdown. |

| Equipment Care | Regularly inspect and clean sieves; ensure stack is clamped tightly. | Maintain accuracy and prevent damage for repeatable results. |

Maximize the accuracy and lifespan of your particle analysis equipment. KINTEK specializes in high-quality lab equipment and consumables, including durable test sieves and reliable sieve shakers designed for precise, repeatable results. Our experts can help you select the right tools and establish optimal procedures for your specific materials. Contact our team today to discuss your laboratory needs and ensure your sieve analysis is a success.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

People Also Ask

- What is the purpose of using high-precision vibrating sieving systems? Master Filler Quality in Wood-Plastic Composites

- What is the role of a sieving system in wet depithing? Optimize Sugarcane Bagasse Cellulose Extraction

- What is the role of a laboratory shaker in PHA research? Accelerate Extremophile Screening & Bioplastic Development

- Why is a laboratory sieving system required for bentonite in coatings? Ensure Flawless Surface Performance

- What is the primary role of an electronic shaker in diesel desulfurization? Optimize Mass Transfer in Lab Research

- How does a standard sieving system contribute to the quality control of recycled concrete aggregates?

- What is the description of a sieve shaker? Automate Particle Size Analysis for Accurate Results

- Why is a benchtop shaker essential during the biosorption experiments of palladium ions (Pd2+)? Maximize Your Ion Yield