The primary safety issues with vacuum pumps stem from four distinct sources: mechanical and electrical hazards from the pump's operation, chemical exposure from the substances being pumped, physical dangers like implosion or pressurization, and environmental factors such as noise and heat. Understanding these risks is not just about the pump itself, but about how it interacts with your entire system and process.

A vacuum pump is not an isolated device; it is the engine of a larger system. The most severe safety risks arise not from the pump in isolation, but from the hazardous materials it moves and the potential energy it stores within the vacuum system.

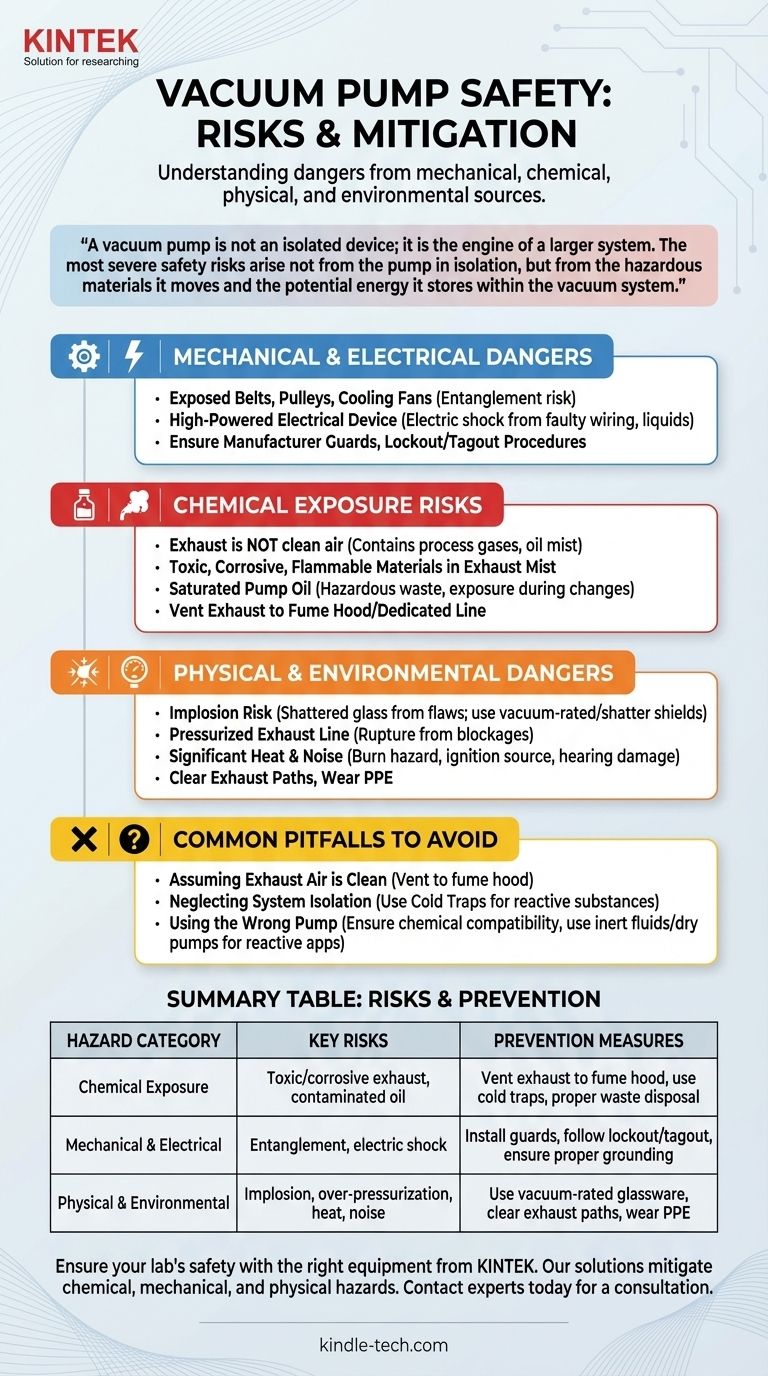

Deconstructing the Primary Hazards

A comprehensive safety assessment requires looking at each potential point of failure or exposure. The dangers can be categorized into clear, manageable groups.

Mechanical and Electrical Dangers

All vacuum pumps are powered machines with moving parts. The most immediate hazards are often the most conventional.

This includes risks from exposed belts, pulleys, and cooling fans, which can cause serious injury through entanglement. It is critical that all manufacturer-supplied guards are kept in place.

Furthermore, pumps are electrical devices, often high-powered. They present a risk of electric shock from faulty wiring, improper grounding, or exposure to liquids. Standard lockout/tagout procedures are essential during maintenance.

Chemical Exposure Risks

This is frequently the most underestimated hazard. The pump's exhaust is not clean air; it is a concentrated stream of whatever substances were drawn from the vacuum system.

If you are pumping toxic, corrosive, or flammable materials, these will be present in the pump's exhaust mist. Venting this exhaust directly into a room can create a severe inhalation hazard or an explosive atmosphere.

The pump oil in oil-sealed pumps can also become saturated with hazardous chemicals, making oil changes a point of significant chemical exposure risk. This contaminated oil is hazardous waste and must be disposed of correctly.

Physical and Environmental Dangers

A vacuum does not "suck"; rather, external atmospheric pressure pushes inward. This immense, invisible force creates significant physical hazards.

The most dramatic risk is implosion. A flaw in a glass vacuum vessel can cause it to shatter inward violently, creating projectile shards. This is why vacuum-rated glassware and shatter shields are critical.

Conversely, improperly venting a pump against a blockage can pressurize the exhaust line, creating a risk of rupture. The exhaust path must always be clear and unobstructed.

Finally, pumps generate significant heat and noise. High surface temperatures can be a burn hazard or an ignition source for flammable vapors, while prolonged noise exposure can cause permanent hearing damage.

Common Pitfalls to Avoid

Even experienced users can make dangerous assumptions. Recognizing these common mistakes is the first step toward building a robust safety protocol.

Assuming Exhaust Air is Clean

Never assume pump exhaust is safe to breathe. It contains not only the process gases you've pumped but also a fine mist of pump oil (in oil-sealed pumps). This exhaust must be captured and vented safely.

The single most important safety measure is to vent the pump's exhaust into a dedicated exhaust line or a fume hood. This prevents the accumulation of hazardous vapors in your workspace.

Neglecting System Isolation

A vacuum pump is a robust but sensitive piece of equipment. Allowing reactive, corrosive, or high-vapor-pressure liquids to enter the pump will damage it and create a significant safety hazard.

Cold traps, typically cooled with liquid nitrogen or a dry ice slurry, are essential. They condense volatile vapors before they can reach the pump, protecting both the equipment and the user from chemical exposure via the exhaust.

Using the Wrong Pump for the Job

Not all pumps are suitable for all applications. Using a standard oil-sealed pump for highly reactive or oxidizing substances (like oxygen) can lead to a fire or explosion within the pump itself.

Always select a pump that is chemically compatible with the materials you are working with. For reactive applications, specially prepared, inert fluids (like PFPE) or completely dry (oil-free) pumps are necessary.

Making the Right Choice for Your Goal

Your safety strategy should be tailored to your specific application. Different goals introduce different primary risks that must be prioritized.

- If your primary focus is handling volatile or corrosive chemicals: Your top priority must be system isolation with a cold trap and proper ventilation of the pump exhaust to a fume hood.

- If your primary focus is operating in a clean environment: Consider a dry pump to eliminate oil mist contamination, but remain vigilant about managing the higher heat output as a potential ignition source.

- If your primary focus is general mechanical or physics applications: Concentrate on fundamental safety, including mechanical guarding, electrical checks, and using shields or wrapped glassware to mitigate implosion risks.

Ultimately, a proactive safety culture is the most effective defense against the inherent hazards of working with vacuum systems.

Summary Table:

| Hazard Category | Key Risks | Prevention Measures |

|---|---|---|

| Chemical Exposure | Toxic/corrosive exhaust, contaminated oil | Vent exhaust to fume hood, use cold traps, proper waste disposal |

| Mechanical & Electrical | Entanglement, electric shock | Install guards, follow lockout/tagout, ensure proper grounding |

| Physical & Environmental | Implosion, over-pressurization, heat, noise | Use vacuum-rated glassware, clear exhaust paths, wear PPE |

Ensure your lab's safety with the right equipment from KINTEK. Our vacuum pumps and accessories are designed to mitigate chemical, mechanical, and physical hazards. Whether you need oil-sealed, dry, or chemically resistant pumps, we provide solutions tailored to your laboratory's specific needs. Contact our experts today for a consultation on selecting the safest vacuum system for your application.

Visual Guide

Related Products

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What role does a temperature-controlled heating reaction device play in the synthesis of akaganeite nanorods?

- How is the pressure and temperature process used to make a synthetic diamond? Replicate Earth's Diamond Formation in a Lab

- What are the disadvantages of centrifugal separators? High Costs and Performance Limitations

- How do you increase sputtering yield? Optimize Ion Energy, Mass, and Angle for Maximum Deposition

- How can we reduce porosity of sintering? Optimize Your Process for Maximum Density

- How is a sample analysis done in FTIR? A Step-by-Step Guide to Reliable Results

- What process is used to extract essential oils? From Crude Plant to Pure Perfume

- What is extruded graphite? Understanding Its Anisotropic Properties for Cost-Effective Solutions